Key Highlights

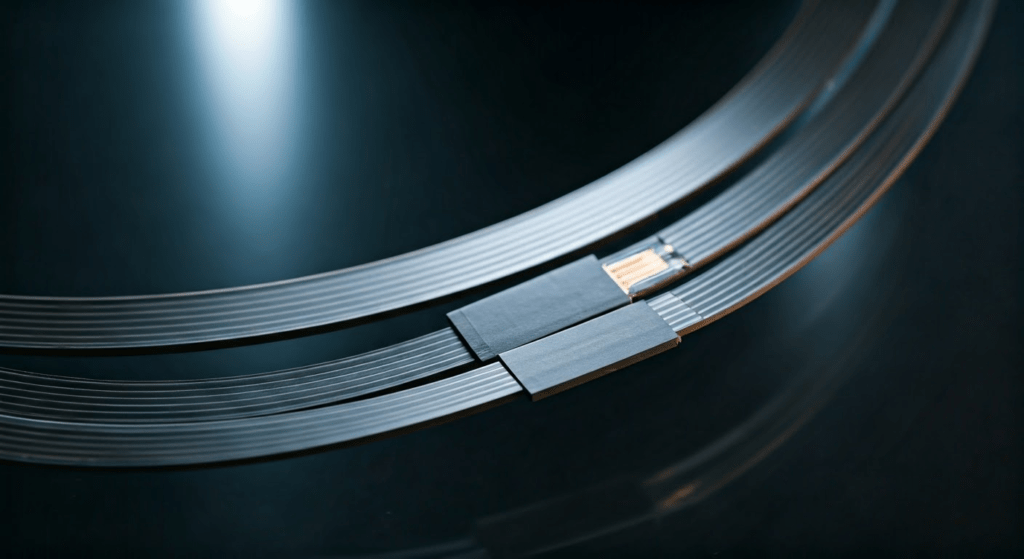

- Flexible flat cables (FFCs) are thin, flat wires used in small electronic devices.

- FFCs are excellent for confined areas as they have the ability to bend easily. This makes them ideal for smart designs.

- You can find FFCs in a range of gadgets such as smartphones, laptops, tablets, cars, airplanes, and medical devices.

- They come in several types and styles, with different conductors, pitches, and insulation materials.

- FFCs are simpler to work with than regular wires. They help cut costs and are more reliable.

Introduction

In today’s digital world, being small and flexible is important. Flexible flat cables, known as FFCs, play a big role in many devices. They carry electrical signals while staying flat and compact. This is useful when there isn’t much space. In this blog, we will cover the basics of FFCs. We will look at the types, the advantages of saving space, and how they are used in modern electronics.

Exploring the Basics of Flexible Flat Cables (FFC)

Flexible Flat Cables, or FFCs, are useful in many areas. There are types called low insertion force and zero insertion force. FFCs usually have ZIF connectors. These connectors make it simple to attach cables. The cables have conductors that help manage impedance. This ensures quick data transfer. FFCs can also offer custom solutions with bottom contacts. You can find them in LVDS and LIF applications. This shows how important they are in automation and electronics.

Defining FFC and Its Unique Characteristics

A flat flexible cable, or FFC, is made of several flat wires that are placed close together. These wires are spaced evenly and are covered with a non-conductive material. FFCs are thin and very flexible. This design makes them easier to use than round cables. They are great for tight spaces where you need something compact and bendable.

One important part of an FFC is controlled impedance. This feature helps keep signals clear and strong. It is very important when signals move quickly and over long distances. Controlled impedance stops signal reflection and distortion. FFC cables are made to match the right impedance standards. This makes them great for fast data transfer and places where there might be signal interference.

The sleek and thin design minimizes electromagnetic interference (EMI). This is important for today’s electronics. It makes creating circuit designs easier. It also helps produce smaller and more reliable electronic devices.

The Evolution of FFC Technology in the Modern Evolution

The development of FFC technology has made great strides. It started with simple ribbon cables and moved on to flexible printed circuits, known as FPCs, that meet advanced specifications. The first FFCs were used for basic connections. They had only a few conductors and lacked flexibility. But as technology improved, the need for smaller and more flexible electronics grew. This need led to new designs and methods to make FFCs.

A major improvement in FFC technology is using automation in production. Automation speeds up the assembly and makes it more precise. This change allows us to make smaller sizes, thinner paths for conductors, and more complex designs. Now, we can assemble a definitive list of applications apt for compact devices like smartphones and tablets that necessitate high-density connectivity.

New and better materials have made it easier to use FFCs. For example, high-temperature plastics, like polyimide, help FFCs handle heat in cars and planes. The flexibility of FFCs is key for designs with moving parts. This includes features like laptop hinges and the back flip options in smartphones.

Diving Into the Different Types of FFC

Understanding the different types of FFCs is important for choosing the right cable. FFCs come in various shapes and sizes. They also differ in materials, pitch sizes, insulation, and contact designs. These differences help engineers select the best FFC for their needs. This includes how much current it can handle, the voltage it can support, and how flexible it needs to be.

- Two main types of FFCs exist: standard and custom designs.

- Standard FFCs are good for regular uses.

- Designers create custom designs for special needs.

- When choosing between standard and custom FFCs, think about how complex your project is.

- Also, consider the space you have and your budget.

Standard vs. Custom FFC Designs

Standard FFCs are easy to find. They have helpful features that can save you money for different needs. These cables come in common sizes. They have various numbers of conductors and types of insulation. You can use standard FFCs to connect screens in laptops and smartphones. They can also carry signals in printers and scanners. (Learn more about FFC standard)

Custom FFC solutions are important when you need special designs or have limited space. They offer a variety of sizes, conductor setups, and materials. This allows manufacturers to create cable assemblies that fit their product needs perfectly. Custom FFCs are exceptionally useful in complex devices, like medical equipment, where size and reliability matter a lot.

Companies that focus on cable assemblies usually provide custom FFC design and production services. They collaborate with customers to learn their needs. After understanding, they create custom designs and produce cables that match those needs. This teamwork makes sure the final FFC works well for its purpose. It helps improve performance and reduces design issues.

Hua Xian Jing provides high-quality LCD FPC, LCD FFC, and LCD PCB customization services.

Key Variations: Pitch, Conductors, and Insulation

When choosing an FFC for your needs, consider three important factors: pitch, conductors, and insulation. Each part is essential for the cable’s performance. They also help decide if it will work in various environments and meet electrical needs.

Pitch is the gap between the centers of wires in a flat flexible cable (FFC), with various actuator types influencing design considerations. A smaller pitch lets more wires fit into a smaller width. This is key for making compact devices. FFCs often have pitch sizes from 0.5mm to 2.54mm. A 0.5mm pitch provides the most compact layout. Choosing the right pitch depends on the space you have and how many conductors you need.

The type and size of conductors in an FFC affect how much current they can handle and their electrical resistance. Copper is normally the best choice for conductors in FFCs because it is good at using electricity. We usually measure the size of the conductor using AWG, which stands for American Wire Gauge. A lower AWG number means a thicker conductor. A thicker conductor can carry more current safely.

The insulation material protects the conductors from outside factors. It guards against moisture, dust, and damage. This helps everything function properly and keeps the signals clear. Some typical insulation materials used in FFCs are polyester, polyimide, and FEP (fluorinated ethylene propylene).

| Feature | Description |

|---|---|

| Pitch | The distance between adjacent conductors, impacting cable density. |

| Conductors | Typically made of copper, with size influencing current carrying capacity. |

| Insulation | Protective layer guarding against environmental factors and ensuring signal integrity. |

The Advantages of Using Flexible Flat Cables

FFC designs are perfect for small spaces and curved shapes. They maintain a strong signal, which helps create products that are detailed and compact. Their lightweight nature also lowers the overall weight of the device. This is important for gadgets that you can carry around easily.

Space Efficiency and Flexibility for Complex Designs

Space efficiency is very important for electronics today. FFCs assist with this because they are thin. This feature is vital for new devices. Devices like smartphones and tablets need to be small in size.

FFC designs are very flexible. They can fit several conductors in a small size. This lets different signals travel through one cable. It simplifies things and cuts down on the need for many cables. FFCs help keep wiring tidy and make good use of available space.

FFC flexibility is very useful. They can bend and move multiple times without breaking. This feature is great for jobs that need movement. For example, it helps when a laptop lid opens and closes, or when a robotic arm extends. FFCs keep signals strong and stay whole. This helps electronic devices last longer.

Durability and Reliability in Harsh Environments

FFC cables are great. They are small and strong. They are made carefully and have a protective layer. This layer keeps the inside safe from damage. Because of this, they are perfect for different uses, like home devices and factory equipment.

Using good materials in FFCs makes them dependable. Choosing the best insulation, conductor plating, and shielding helps these cables endure longer. They can also resist issues such as water damage, wear, and high temperatures.

FFC cables are useful in many situations. They work well for cars that travel long distances. They are also good for outdoor areas where the weather changes frequently. These cables can withstand pressure, so they are a reliable choice for different industries.

Common Applications of FFC in Various Industries

FFCs’ unique features are their flexibility, strength, and small size, which make them useful in many industries. FFCs help power the screens on our smartphones and connect devices in cars and planes properly. Thus, they play a key role in the technology we use every day.

Now, let’s look at some important ways FFCs are used. This shows how flexible and important they are in our technology today.

Consumer Electronics: From Smartphones to Home Appliances

The consumer electronics industry depends heavily on FFCs. These FFCs help make devices smaller, allow for flexible designs, and contribute to some of the more common uses. You can see them in many items we use every day. They connect different parts and assist with important functions.

In smartphones and similar devices, FFCs link key parts. These parts include the display, touchscreen, camera, and buttons. A slim design is very important for these small gadgets. It allows signals to travel easily while keeping the device light and compact.

- Smartphones and Tablets: These devices connect the screens, touch areas, and battery parts.

- Laptops and Notebooks: These devices link the screen, keyboard, and touchpad.

- Televisions: These devices send signals to both LCD and LED screens.

- Home Appliances: These devices connect parts in washing machines, refrigerators, and other common items.

The flexibility of FFCs in daily devices shows their effect on the technology we use.

Automotive and Aerospace: Enhancing Connectivity and Performance

Many industries, such as automotive and aerospace, use FFCs. They are strong and perform well in tough situations. These industries need products that can handle high heat, vibrations, and strong chemicals. That’s why FFCs are a great choice.

FFC cables play a key role in cars since they support the electronics. They link different features like:

- Infotainment Systems: These connect screens, GPS devices, and audio systems. They are meant for your enjoyment.

- Advanced Driver-Assistance Systems (ADAS): They use sensors, cameras, and control units. This helps you drive safely.

- Powertrain and Chassis Control: These send signals to manage the engine, brakes, and car stability.

- FFCs are very important in the aerospace field for several reasons.

- In-flight Entertainment Systems: They have screens, speakers, and controls. These provide entertainment during flights.

- Navigation and Communication Equipment: This equipment sends signals that are essential for the plane’s systems.

- Environmental Control Systems: These systems keep the temperature and pressure stable in the aircraft cabin for comfort.

FFCs are used in many areas. They perform well, even in tough conditions. This is why they are important for jobs that focus on safety.

Conclusion

Flexible Flat Cables (FFC) are a great option for PCB applications. They help save space and are very bendable. FFCs also last a long time, making them perfect for complex designs. Their growth has improved connections in several areas. These include consumer electronics, cars, and aerospace. FFCs have special features that can be changed to fit different needs. This makes them better than ordinary wires. However, keep in mind the environmental questions and any limits when creating products. If you want reliable FFC suppliers in the United States, contact us!

Frequently Asked Questions

What Makes FFCs Preferable Over Traditional Wiring?

FFC connectors have many advantages compared to regular wiring. They require less insertion force, making them easier to handle. FFC connectors also simplify the assembly process, allowing for improved design flexibility. Their neat design cuts down on clutter and helps make better use of space.

Can FFCs Be Customized for Specific Applications?

TE Connectivity and other companies create custom FFC designs with specialized contact points. These designs fit the unique requirements of various applications. They can have different amounts of conductors, pitches, lengths, and types of insulation materials.

How Do Environmental Factors Affect FFC Performance?

Environmental factors can affect how well FFCs work and how long they last. Things like very high or low temperatures, humidity, and vibrations matter. It is important to select the right insulation and shielding materials. Choosing the right ones helps FFCs stay strong in tough conditions.

Are There Any Limitations to Using FFC in Product Design?

- FFCs are not great if you need to carry a lot of current.

- They do not bend or twist easily.

- In these cases, other types of cables might be better choices.

Where Can I Find Reliable FFC Suppliers in the United States?

Many trustworthy FFC suppliers are based in the United States. They offer different custom solutions. You can check online directories and industry magazines. These resources can help you find reliable vendors that supply FFCs.