You’re squinting at your LCD screen in bright sunlight, struggling to read the display. This common frustration affects millions of devices daily.

Sunlight-readable LCDs require at least 1,000 nits of brightness, specialized polarizers, anti-reflective coatings, and optical bonding to overcome the approximately 100,000 lux of direct sunlight while maintaining clear visibility.

After 13 years in the LCD industry, I’ve helped countless customers solve this exact problem. The transformation from a washed-out screen to a crystal-clear display involves multiple technologies working together.

Why Do Standard LCDs Fail in Sunlight?

Standard LCDs struggle in sunlight because they face an overwhelming brightness battle. I’ve seen too many projects fail because engineers underestimated this challenge.

Standard LCDs fail in sunlight because their typical 250-450 nit brightness, Sunlight is often over 100 times brighter than typical LCD backlights, instantly overpowering the screen., while surface reflections further reduce visibility and contrast(How Do Sunlight-Readable LCDs Maintain Contrast Outdoors?).

The physics are unforgiving. When you take a standard LCD outdoors, the ambient light reflects off the display surface, creating a bright reflection that washes out the image. This phenomenon becomes even more pronounced when you consider that the human eye requires at least a 2.5:1 contrast ratio to comfortably distinguish content from background.

Why Do Standard LCDs Fail in Sunlight?

Direct sunlight can reach 100,000 lux or more(the sun’s brightness is not measured in nits). Most standard LCDs produce 200-400 nits of brightness. This is not enough.

The brightness calculation isn’t just about raw numbers. You need to consider:

| Ambient Condition | Required Display Brightness | Typical Use Case |

|---|---|---|

| Indoor office (200-500 lux) | 200-300 nits | Computer monitors, tablets |

| Shaded outdoor (1,000-5,000 lux) | 500-800 nits | Covered patios, vehicle cabins |

| Bright outdoor (10,000+ lux) | 1,000+ nits | Direct sunlight applications |

| Intense sunlight (100,000+ lux) | 2,000+ nits | Desert, snow, marine environments |

What Role Do Reflections Play in Display Visibility?

Reflections compound the brightness challenge significantly. When I measure typical LCD displays with touch screens, they reflect approximately 14% of ambient light back to the viewer.

The reflection problem has multiple layers:

Surface Reflections: These occur at the top glass layer and are the most visible. They create mirror-like images that directly compete with display content.

Internal Reflections: These happen between different layers within the display stack. Air gaps between the LCD panel and cover glass create additional reflection surfaces.

Fresnel Reflections: These occur at every interface where light passes between materials with different refractive indices. Uncoated glass typically reflects 4% of incident light.

The cumulative effect means that a standard LCD in bright sunlight faces both the challenge of insufficient brightness and excessive reflected light. This creates a double disadvantage that standard displays cannot overcome.

What Are the Core Technologies That Make LCDs Sunlight Readable?

Multiple technologies must work together to create truly sunlight-readable displays. I’ve implemented these solutions across hundreds of projects.

Core sunlight-readable technologies include high-brightness LED backlights (1,000+ nits), specialized polarizers (reflective or transflective), anti-reflective surface treatments, and optical bonding to eliminate air gaps and reduce reflections.

How Do High-Brightness Backlights Overpower Sunlight?

High-brightness backlights form the foundation of sunlight readability. The approach is straightforward: generate enough light to overpower ambient conditions.

Modern LED backlights can achieve 2,000+ nits through several methods:

Increased LED Density: More LEDs per unit area provide higher total light output. Where standard backlights might use 20-30 LEDs per square inch, high-brightness versions can use 50-100.

Higher Drive Currents: LEDs can be driven at higher currents for increased brightness, though this affects lifespan and heat generation.

Improved Optical Design: Enhanced reflectors and light guides maximize light utilization efficiency.

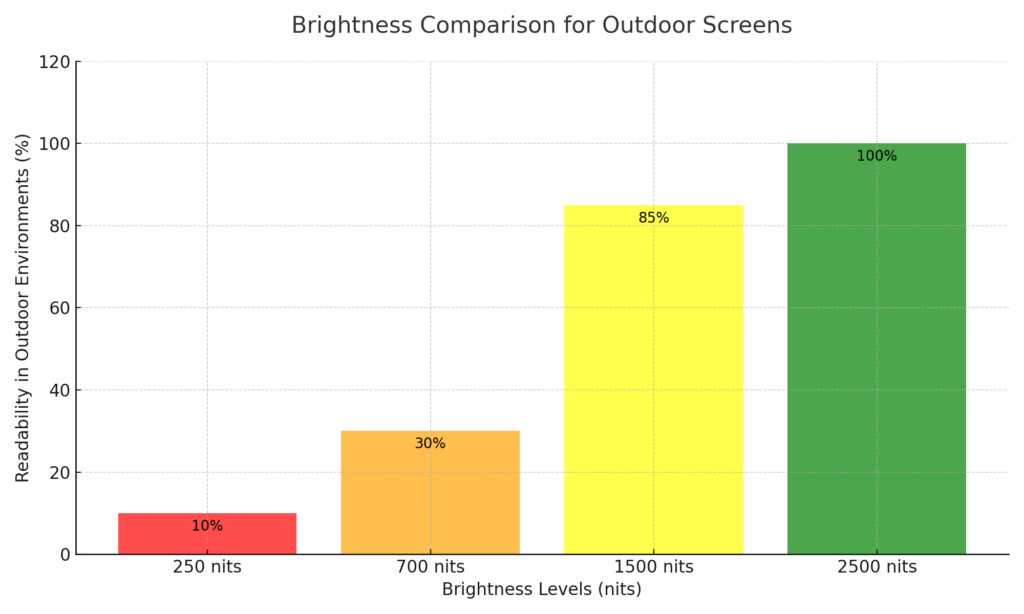

What Nit Levels Are Required for Different Lighting Conditions?

The nit requirements scale with ambient light conditions:

Indoor Applications (200-300 nits): Standard office lighting requires minimal brightness. Most commercial displays operate comfortably in this range.

Covered Outdoor (500-800 nits): Shaded patios or covered areas need moderate brightness increases. Vehicle displays often operate in this range.

Bright Outdoor (1,000-1,500 nits): Direct sunlight applications need significant brightness. This is the minimum for true sunlight readability.

Extreme Conditions (2,000+ nits): Marine, desert, or snow environments require maximum brightness. Professional outdoor signage often operates here.

I’ve measured displays in various conditions. A 1,000-nit display that looks excellent in partial shade becomes difficult to read in direct noon sun. The 2,500-nit displays I’ve tested in outdoor kiosks remain clearly visible even in intense sunlight.

How Do LED Backlights Achieve Ultra-High Brightness?

LED technology improvements enable higher brightness levels:

Improved LED Efficiency: Modern LEDs produce 100-200 lumens per watt, compared to 50-70 lumens per watt for older technologies.

Better Heat Management: Heat sinks, thermal interfaces, and air circulation prevent LED degradation at high drive levels.

Advanced Driver Circuits: Switching power supplies and current regulation maintain stable brightness across temperature ranges.

Zoned Backlighting: Local dimming zones can boost brightness in specific areas while maintaining overall efficiency(What is HDR Technology: Local Dimming, Global Dimming).

The trade-off is power consumption. High-brightness backlights consume 10-20x more power than standard versions. A 1,000-nit display might consume 50-100 watts compared to 5-10 watts for a standard display.

How Do Specialized Polarizers Work With Ambient Light?

Polarizers represent a clever approach to sunlight readability. Instead of fighting ambient light, they harness it(What Sets Transmissive, Reflective, and Transflective LCDs Apart?).

Reflective Polarizers: These act like mirrors, reflecting ambient light back to the viewer. The brighter the environment, the more readable the display becomes.

Transflective Polarizers: These combine reflective and transmissive properties, using ambient light when available and backlight when needed.

Transmissive Polarizers: Standard polarizers that block ambient light and rely entirely on backlight.

I’ve tested all three types extensively. Reflective polarizers work brilliantly in bright conditions but become unreadable in darkness. Transflective polarizers offer the best compromise for battery-powered devices.

When Are Reflective Polarizers the Better Choice?

Reflective polarizers excel in specific applications:

Always-On Displays: Information displays that don’t need backlighting save significant power.

Battery-Powered Devices: Handheld instruments benefit from reduced power consumption.

Extreme Brightness Environments: Marine and desert applications where even 2,000-nit backlights struggle.

Cost-Sensitive Applications: Eliminates backlight costs and complexity.

The limitations are significant. Reflective displays cannot be used in dark environments without additional edge lighting. Color reproduction is also limited compared to backlit displays.

What Surface Treatments Minimize Glare and Reflections?

Surface treatments form the final line of defense against reflections. I’ve seen dramatic improvements from proper coatings(What’s the Difference Between Anti-Glare and Anti-Reflective Coatings for LCD Screens?).

Anti-Reflective (AR) Coatings: These use thin-film interference to cancel reflected light waves.

Anti-Glare (AG) Coatings: These scatter reflected light to reduce concentrated glare.

Anti-Fingerprint (AF) Coatings: These prevent oil and water marks that increase reflections.

How Do Anti-Reflective Coatings Improve Clarity?

Anti-reflective coatings work through destructive interference. Multiple transparent layers create phase shifts that cancel reflected light.

The process involves:

Layer Thickness: Each layer is precisely 1/4 wavelength thick for specific colors.

Refractive Index Matching: Sequential layers have carefully controlled refractive indices.

Multi-Layer Design: Professional coatings use 3-7 layers for broadband effectiveness.

Properly applied AR coatings can reduce reflections from 4% to less than 1%. This represents a 4x improvement in contrast ratio under bright conditions.

What's the Difference Between Anti-Glare and Anti-Reflective Treatments?

The distinction is important for application selection:

Anti-Glare (AG):

- Creates a matte surface through microscopic texturing

- Scatters light to reduce concentrated reflections

- Reduces overall brightness by 12-15%

- Better for high-traffic public displays

Anti-Reflective (AR):

- Uses optical interference to cancel reflections

- Maintains high transparency (99%+)

- Provides clearer images with better contrast

- Better for precision applications

I recommend AG coatings for outdoor kiosks and public displays where finger smudges are common. AR coatings work better for vehicle displays and professional equipment where clarity is paramount.

How Does Optical Bonding Enhance Sunlight Readability?

Optical bonding eliminates air gaps that create internal reflections. This technology has transformed outdoor display performance(Bonding Technology: Optical Bonding vs Air Bonding).

Optical bonding fills air gaps between display layers with optically clear adhesive, eliminating internal reflections, improving contrast by up to 400%, and enhancing durability against shock and vibration.

What Happens During the Optical Bonding Process?

The optical bonding process requires precision manufacturing:

Surface Preparation: All surfaces must be perfectly clean and decontaminated.

Adhesive Application: Optically clear adhesive is applied evenly across the entire surface.

Lamination: The cover glass is carefully positioned to avoid bubbles or gaps.

Curing: UV light or heat cures the adhesive to create a permanent bond.

The process must be performed in clean room conditions to prevent contamination. Even microscopic particles can create visible defects in the finished display.

There are several adhesive types:

Liquid Adhesives (LOCA): Provide excellent optical clarity but require careful handling.

Dry Film Adhesives (DFA): Easier to apply but may have slightly lower optical performance.

Silicone Adhesives: Offer excellent durability and reworkability.

What Are the Measurable Benefits of Optical Bonding?

The improvements are quantifiable:

Reflection Reduction: Internal reflections drop from 8-12% to 2-3%.

Contrast Improvement: Contrast ratios increase by 300-400%.

Brightness Efficiency: More backlight reaches the viewer, improving efficiency.

Durability Enhancement: Bonded displays resist shock and vibration better.

Moisture Protection: Eliminates condensation between layers.

I’ve measured these improvements directly. A standard 1,000-nit display with optical bonding outperforms a 1,500-nit display without bonding in bright conditions.

What Are the Critical Trade-offs in Sunlight-Readable Design?

Every sunlight-readable feature comes with compromises. Understanding these trade-offs helps in making informed decisions.

Critical trade-offs include increased power consumption (10-20x higher), heat generation requiring thermal management, higher costs, and reduced battery life in portable applications.

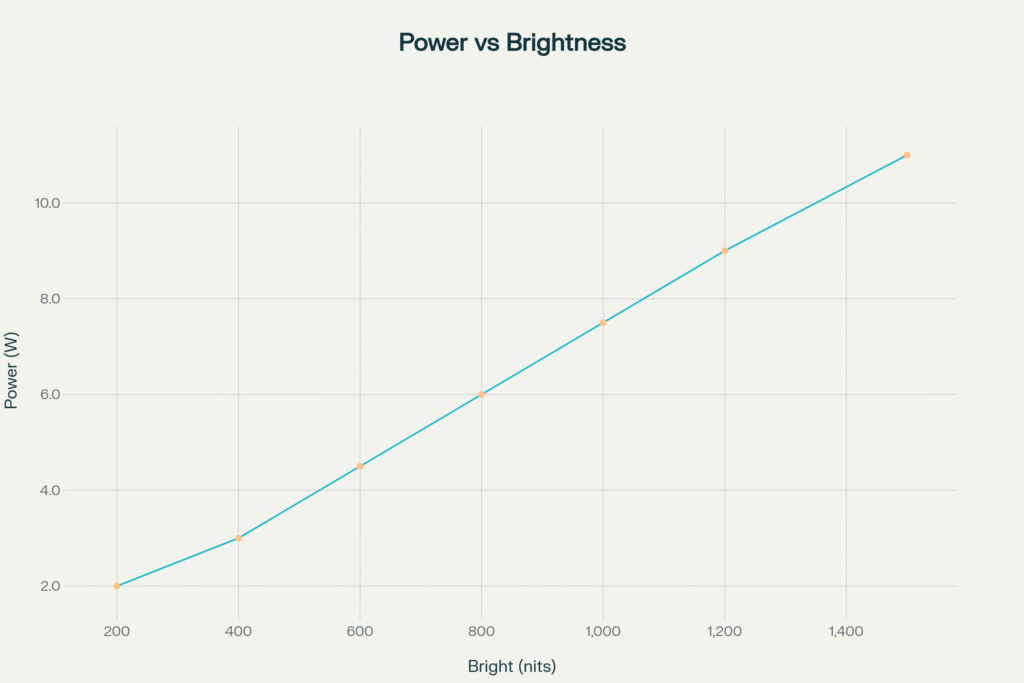

How Does High Brightness Affect Power Consumption?

Power consumption scales dramatically with brightness:

Standard Display (300 nits): 5-10 watts typical consumption.

High-Brightness Display (1,000 nits): 50-100 watts typical consumption.

Ultra-High-Brightness Display (2,500 nits): 100-200 watts typical consumption.

The relationship isn’t linear. LED efficiency decreases at higher drive currents, and thermal management systems require additional power(How can I reduce LCD power consumption in embedded systems?).

What's the Real Impact on Battery Life?

For battery-powered devices, the impact is severe:

Tablet Application: Battery life drops from 8-10 hours to 2-3 hours.

Handheld Instruments: Operating time reduces from days to hours.

Vehicle Displays: Significant alternator load increases fuel consumption.

I’ve worked with customers who needed to redesign their entire power systems to accommodate high-brightness displays. The power requirements often exceed the original device specifications.

How Do Manufacturers Manage Heat Generation?

Heat management becomes critical at high brightness levels:

Passive Cooling: Heat sinks, thermal pads, and aluminum housings.

Active Cooling: Fans, heat pipes, and liquid cooling systems.

Thermal Management ICs: Automatic brightness reduction at high temperatures.

Duty Cycle Control: Pulsed operation to reduce average power consumption.

Professional outdoor displays often include temperature sensors that automatically reduce brightness when internal temperatures exceed safe limits.

How Can You Determine If a Display Is Truly Sunlight Readable?

Marketing claims often exceed reality. Proper evaluation requires understanding specifications and testing methods(What Temperature Range Can LCD Modules Safely Operate In?).

True sunlight readability requires at least 1,000 nits measured brightness, less than 3% total reflectance, wide operating temperature range (-20°C to +70°C), and verification through actual outdoor testing.

What Specifications Should You Look For?

Critical specifications include:

Brightness Rating: Minimum 1,000 nits, preferably 1,500+ nits.

Contrast Ratio: At least 800:1, preferably 1,000:1 or higher.

Reflectance: Less than 3% total reflectance.

Operating Temperature: -20°C to +70°C minimum range.

Viewing Angle: 160° or better horizontal and vertical.

How Do You Interpret Nit Ratings and Brightness Claims?

Nit ratings require careful interpretation:

Peak vs. Sustained: Some displays achieve peak brightness only briefly.

Test Conditions: Measurements at room temperature vs. operating temperature.

Uniformity: Brightness consistency across the display area.

Lifetime: Brightness degradation over time.

I always request detailed test reports showing brightness measurements under actual operating conditions. Laboratory measurements often don’t reflect real-world performance.

What Are the Practical Applications and Use Cases?

Sunlight-readable displays serve critical roles across multiple industries. Understanding applications helps guide technology choices.

Key applications include automotive displays, marine electronics, outdoor digital signage, industrial equipment, military devices, and medical equipment requiring outdoor visibility and reliability.

Where Are Sunlight-Readable Displays Most Critical?

Mission-critical applications include:

Automotive Dashboards: Driver safety depends on clear visibility.

Marine Navigation: GPS and radar displays must work in bright conditions.

Aviation Instruments: Cockpit displays require extreme reliability.

Industrial Controls: Outdoor machinery needs readable interfaces.

Military Equipment: Tactical displays must function in any environment.

Medical Devices: Portable ultrasound and diagnostic equipment.

Which Industries Require Sunlight-Readable Technology?

Industry-specific requirements:

Transportation: Vehicle displays, traffic management systems.

Agriculture: Tractor guidance systems, crop monitoring equipment.

Construction: Heavy equipment controls, surveying instruments.

Oil and Gas: Pipeline monitoring, wellhead controls.

Utilities: Solar panel monitoring, grid management displays.

Public Safety: Emergency vehicle displays, communication systems.

Each industry has unique requirements for brightness, durability, and environmental resistance.

How Do Mobile Devices Achieve Sunlight Readability?

Modern smartphones demonstrate advanced techniques:

Adaptive Brightness: Automatic adjustment based on ambient light sensors.

Peak Brightness Modes: Temporary high-brightness operation.

OLED Advantages: Self-emissive pixels provide better contrast.

Power Management: Intelligent brightness control to preserve battery.

Screen Coating: Advanced anti-reflective treatments.

The iPhone 16 achieves 2,000 nits peak brightness, while the Galaxy S25 reaches 2,600 nits. These represent the current state-of-the-art in mobile display technology.

What Are the Emerging Trends in Sunlight-Readable Technology?

New developments promise improved performance:

MicroLED Displays: Direct emission provides higher brightness with lower power.

Quantum Dot Enhancement: Improved color gamut and brightness efficiency.

AI-Driven Optimization: Machine learning for automatic brightness adjustment.

Flexible Displays: Curved and bendable sunlight-readable screens.

Transparent Displays: See-through screens for augmented reality applications.

How Are New Display Technologies Improving Outdoor Visibility?

Emerging technologies address current limitations:

E-Ink Color Displays: Extremely low power with excellent sunlight readability.

Transflective OLED: Combines OLED contrast with ambient light utilization.

Holographic Displays: Three-dimensional visualization for complex data.

Adaptive Optics: Real-time adjustment of display characteristics.

Integrated Sensors: Built-in light and proximity sensing.

These technologies promise to solve the fundamental trade-offs between brightness, power consumption, and cost.

How Can You Optimize Existing Displays for Better Sunlight Visibility?

Not every application requires a complete display replacement. Several optimization strategies can improve existing displays.

Immediate improvements include adjusting screen positioning, adding external shading, increasing brightness settings, using light-colored backgrounds, and implementing automatic brightness controls.

What Immediate Solutions Can Improve Current Display Visibility?

Quick fixes I recommend:

Tilt Adjustment: Angle displays to minimize direct reflections.

Brightness Maximization: Use highest available brightness settings.

Background Optimization: Light backgrounds require less backlight power.

Contrast Enhancement: Increase contrast settings for better definition.

Polarizing Filters: Add external polarizers to reduce glare.

How Can Screen Positioning and Shading Help?

Physical modifications often provide significant improvements:

Viewing Angle Optimization: Position displays perpendicular to primary viewing direction.

Shadow Creation: Add hoods, visors, or overhangs to block direct light.

Orientation Adjustment: Rotate displays to minimize sun exposure.

Distance Optimization: Closer viewing reduces ambient light impact.

Reflection Elimination: Remove nearby reflective surfaces.

I’ve seen 50% improvements in readability from proper positioning alone. These solutions cost nothing but require thoughtful implementation.

What Software and Settings Adjustments Make a Difference?

Software optimizations can help:

Brightness Scheduling: Automatic brightness adjustment based on time of day.

Contrast Boosting: Software enhancement of display contrast.

Color Temperature Adjustment: Warmer colors often appear brighter.

Font Optimization: Larger, bolder fonts improve readability.

Background Adaptation: Light backgrounds for outdoor use.

When Should You Consider Display Upgrades?

Upgrade indicators include:

Persistent Readability Problems: Current display inadequate for application.

Safety Concerns: Visibility issues affecting operation.

Competitive Pressure: Market demands better performance.

Technology Availability: New solutions solve specific problems.

Cost Justification: Productivity improvements justify investment.

What Are the Indicators That Your Current Display Is Insufficient?

Warning signs I watch for:

User Complaints: Consistent feedback about visibility problems.

Workaround Behaviors: Users seeking shade or adjusting positions.

Reduced Productivity: Tasks taking longer due to display issues.

Safety Incidents: Visibility-related accidents or near-misses.

Competitive Disadvantage: Competitors offering better solutions.

When multiple indicators align, upgrade becomes necessary for business success.

Conclusion

Sunlight-readable LCD technology represents a complex engineering challenge that requires multiple coordinated solutions. High-brightness backlights, specialized polarizers, anti-reflective coatings, and optical bonding must work together to overcome the fundamental physics of outdoor visibility.

The trade-offs are significant – increased power consumption, higher costs, and thermal management challenges. However, for applications where outdoor visibility is critical, these compromises become acceptable in exchange for clear, readable displays in any lighting condition.

As emerging technologies like MicroLED and adaptive optics mature, we can expect improvements in efficiency and cost-effectiveness. Until then, understanding the current technologies and their proper application remains essential for successful outdoor display implementations.

The key is matching technology choices to specific application requirements, testing thoroughly in real-world conditions, and planning for the complete system implications of sunlight-readable displays.

Related Articles:

What Is the Difference Between Static and Dynamic Contrast Ratio?

What Exactly Are DPI and PPI, and Why Do They Derail Design Projects?

Are OLED Screens Bad for Your Eyes Long Term?

What is the difference between OLED and AMOLED? What are its advantages?

What is Electrostatic Discharge (ESD) and How Can You Prevent It?

FAQ

How long do sunlight-readable LCD displays typically last in outdoor environments?

Sunlight-readable LCD displays typically last 3-5 years in outdoor environments, with high-quality displays reaching 7-10 years when properly maintained. However, UV exposure, temperature extremes, and continuous high-brightness operation can reduce lifespan by 30-50% compared to indoor displays.

Can I upgrade my existing standard LCD display to make it sunlight-readable?

While you can optimize existing displays through positioning, software adjustments, and add-on anti-glare films, you cannot truly upgrade a standard LCD to full sunlight readability. Standard displays lack the high-brightness backlights (1,000+ nits) and optical bonding necessary for outdoor visibility, making replacement with purpose-built displays the only effective solution.

Why does my sunlight-readable display still look dim even at maximum brightness?

Your display may appear dim due to several factors: ambient light levels exceeding the display’s brightness capacity, thermal throttling reducing brightness in high temperatures, LED backlight degradation over time, or reflections from the screen surface. Additionally, some displays cannot sustain peak brightness continuously, leading to reduced performance under extended operation.

What's the difference between nits rating and actual outdoor performance?

Nits ratings are typically measured in dark room conditions and don’t reflect real-world outdoor performance. A display rated at 1,000 nits may only achieve 600-700 nits in actual outdoor conditions due to temperature effects, viewing angles, and ambient light interference. Look for displays with sustained brightness specifications and Weber contrast ratios for accurate outdoor performance assessment.

Are transflective displays better than high-brightness displays for battery-powered applications?

Transflective displays are significantly better for battery-powered applications as they consume 70-80% less power than high-brightness displays by utilizing ambient light. However, they typically cost 2-3 times more than high-brightness displays and may have limited size options. For applications requiring long battery life, transflective displays provide superior energy efficiency despite the higher initial cost.