Electrostatic discharge (ESD) can ruin delicate displays. As an LCD professional, I’ve seen costly damage from static. Let’s explore proven methods to safeguard displays effectively.

To protect displays from ESD damage, use grounding wrist straps, ESD mats, static-dissipative packaging, and maintain 60% humidity. Handle displays carefully, avoiding static-generating materials and direct contact with sensitive components.

I once saw a batch of displays fail due to improper handling. This experience drives my passion for sharing ESD protection strategies to save you from similar losses.

What is Electrostatic Discharge (ESD) and Why is It a Threat to Displays?

ESD can destroy displays instantly. I’ve witnessed static sparks ruin circuits. Understanding ESD’s threat is the first step to protecting your displays.

Electrostatic discharge (ESD) is a sudden electricity flow between charged objects, often imperceptible. It threatens displays by damaging delicate circuits, causing immediate failure or latent issues that shorten lifespan.

The Science and Impact of ESD

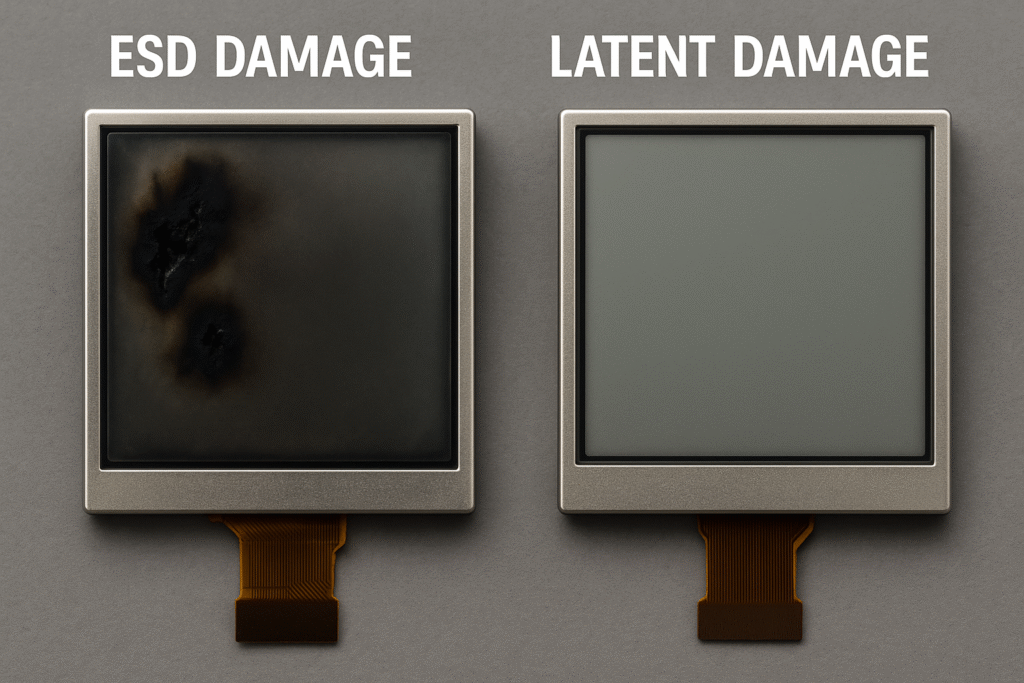

ESD, or electrostatic discharge, occurs when static electricity jumps between two objects. A charge as low as 100 volts can harm sensitive display components like thin-film transistors. I’ve seen displays fail completely or develop intermittent issues due to latent ESD damage. The “esd meaning” lies in its ability to disrupt electronic functionality silently.

1. Why Displays Are Vulnerable

Display1s, especially LCDs, have intricate circuitry. Static can arc through tiny gaps, burning out transistors or connections. This makes “electrostatic sensitive” components like displays prime targets for ESD damage.

2. Types of ESD Damage

| Damage Type | Description | Impact on Displays |

|---|---|---|

| Catastrophic | Immediate failure | Display stops working entirely |

| Latent | Delayed issues | Intermittent glitches, reduced lifespan |

3. Common ESD Sources

- Human body (e.g., walking on carpet)

- Non-ESD-safe tools or packaging

- Low-humidity environments

Understanding “what does ESD stand for” and its risks helps you prioritize protection. Displays are costly, and ESD prevention saves time and money.

What Essential Equipment and Materials Are Needed for ESD Protection?

Choosing the right tools prevents ESD damage. I’ve tested many solutions over the years. Let’s discuss the must-have equipment for display safety.

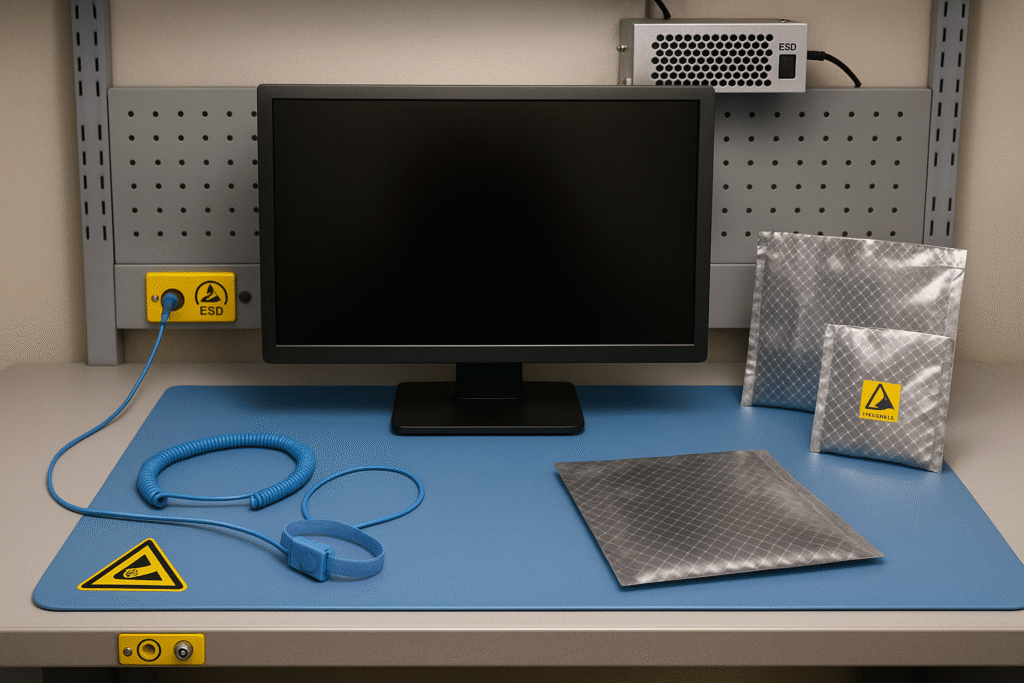

Essential ESD protection equipment includes grounding wrist straps, ESD mats, static-dissipative packaging, ESD flooring, and ionizers. Use grounded tools and maintain a clean, static-free workspace for optimal protection.

Building an ESD-Safe Toolkit

To create an “esd safe” environment, you need specific tools and materials. I’ve set up workspaces that prevent static buildup, and these are the essentials I rely on.

Key ESD Protection Equipment

To create an “esd safe” environment, you need specific tools and materials. I’ve set up workspaces that prevent static buildup, and these are the essentials I rely on.

Why Each Tool Matters

- Grounding Wrist Straps: These “esd wrist straps” connect you to a grounded surface, safely dissipating static. I always test them with an “esd wrist strap tester” to ensure they work.

- ESD Mats: Made of “static dissipative materials,” these mats prevent charge buildup on work surfaces. They’re critical for any “electrostatic workbench.”

- Static-Dissipative Packaging: Unlike regular plastic, “electrostatic discharge packaging” prevents static accumulation. I use anti-static bags for all display storage.

- ESD Flooring and Footwear: “Esd flooring” paired with “esd shoe straps” or “esd heel straps” keeps personnel grounded, especially in large factories.

- Ionizers: These “static eliminators” neutralize charges on insulators, where grounding isn’t possible.

Avoid “static-generating materials” like styrofoam or vinyl. I once saw a display damaged because it was stored in a regular plastic bag. Using “esd products” like anti-static gloves and grounded tools ensures comprehensive protection.

How Should Displays Be Handled to Prevent ESD Damage?

Choosing the right tools prevents ESD damage. I’ve tested many solutions over the years. Let’s discuss the must-have equipment for display safety.

Essential ESD protection equipment includes grounding wrist straps, ESD mats, static-dissipative packaging, ESD flooring, and ionizers. Use grounded tools and maintain a clean, static-free workspace for optimal protection.

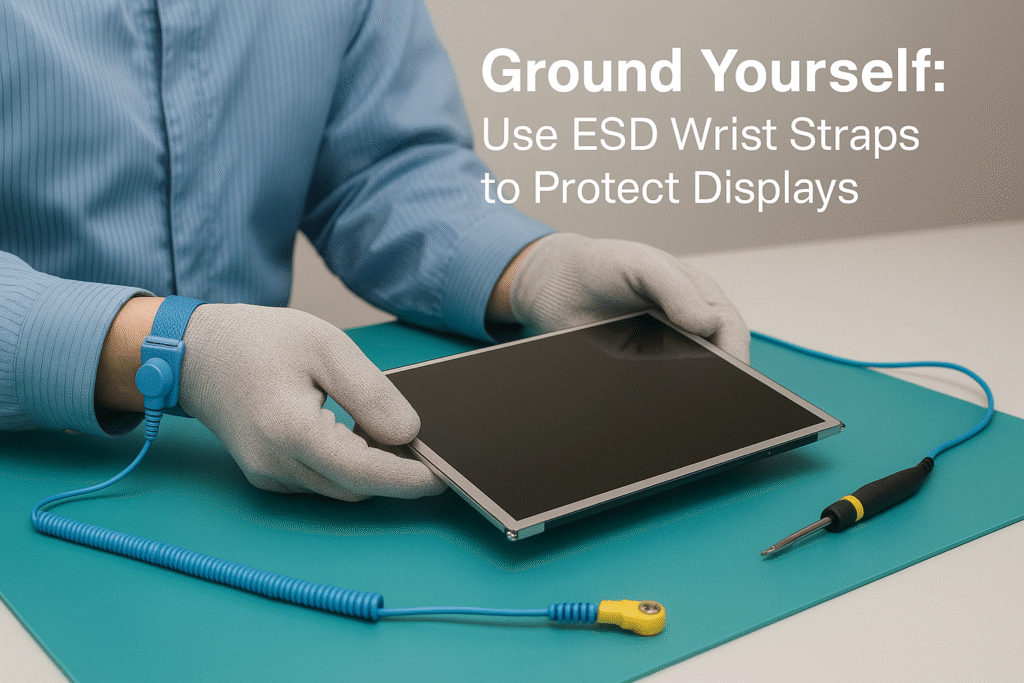

Safe Handling Practices

Careful handling prevents costly ESD damage. I’ve seen displays ruined by a single careless touch. Here’s how to handle them safely.

Key Handling Guidelines

| Action | Why It Matters | Best Practice |

|---|---|---|

| Minimize Contact | Prevents charge transfer | Hold displays by edges or frame |

| Ground Before Handling | Equalizes potential | Touch a grounded surface first |

| Use ESD Mats | Provides safe surface | Place displays on mats when idle |

| Power Off Devices | Reduces ESD pathways | Disconnect power before handling |

Practical Tips

- Avoid Sensitive Areas: Never touch “electrostatic sensitive” parts like flex cables or circuit boards. I always hold displays by their frame to stay safe.

- Ground Yourself: Before handling, touch a “grounded surface” like an ESD mat or metal ground point. This “electrostatic discharge procedure” prevents static transfer.

- Proper Storage: When not working on a display, place it in “static dissipative packaging” or on an “esd mat.” I never leave displays on regular surfaces.

- Use ESD-Safe Tools: Ensure all tools, like screwdrivers, are “esd safe” to avoid accidental charge transfer.

I once saw a technician damage a display by touching its circuit board without grounding. Following these “esd procedures” eliminates such risks.

How Should LCD Factory Controls Prevent ESD?

Factories must prioritize ESD control to protect displays. I’ve overseen production lines with robust systems. Let’s explore how factories can ensure ESD safety.

LCD factories should implement ESD flooring, grounding wrist straps, humidity control at 60%, ionizers, and regular ESD training. Use static-dissipative packaging and test equipment routinely for compliance.

Factory-Wide ESD Strategies

Running an ESD-safe factory requires a comprehensive approach. I’ve helped set up production lines that minimize ESD risks. Here’s what works.

Key Handling Guidelines

| Control | Purpose | Implementation |

|---|---|---|

| ESD Flooring | Grounds personnel | Install conductive flooring |

| Humidity Control | Reduces static buildup | Maintain 60% humidity |

| Ionizers | Neutralizes charges | Place in assembly areas |

| ESD Training | Educates staff | Conduct regular sessions |

Building an ESD Program

- ESD Flooring and Footwear: “Esd flooring” paired with “esd shoe straps” ensures workers stay grounded. I’ve seen factories reduce ESD incidents significantly with this setup.

- Humidity Control: Keep workspace humidity at 60% to dissipate static naturally. I use hygrometers to monitor levels daily.

- Ionizers: In areas with insulators, “static eliminators” like ionizers neutralize charges. They’re essential for high-volume production.

- Training and Signage: Regular “esd training” teaches workers about “esd safety” and the “esd symbol.” I use “esd warning” signs to mark protected areas.

- Equipment Testing: Routine “esd testing” of wrist straps, mats, and flooring ensures reliability. I schedule weekly checks to maintain compliance.

- Packaging Standards: All displays should be stored and shipped in “electrostatic discharge packaging” to prevent static buildup.

I once visited a factory where poor ESD controls led to a 20% defect rate. Implementing these measures dropped defects to near zero.

Conclusion

Protecting displays from ESD requires grounding, careful handling, and factory-wide controls. Use wrist straps, ESD mats, and maintain humidity to ensure display longevity.

Related Articles:

What Is a Glass Substrate in the TFT LCD Industry?

How Do LCD Modules Withstand Salt-Fog Environments?

What Causes Crosstalk in LCDs and Why Do Active Matrix LCDs Perform Better?

Why Do Some LCD Modules Require a Negative Voltage for Contrast Adjustment?

What Is the Difference Between Capacitive and Resistive Touch Screens?

FAQ

What is the ESD symbol?

The ESD symbol is a yellow triangle with a hand and a line, showing that a product is electrostatic sensitive.

Can ESD damage be repaired in displays?

Most ESD damage is permanent. Prevention is much more effective than repair.

What is the most important ESD protection device?

The ESD wrist strap is the most basic and effective personal ESD protection device.

Does high humidity prevent all static problems?

High humidity reduces, but does not eliminate, the risk of static. ESD control measures are still required.

Can regular plastic bags be used for display storage?

No, regular plastics generate static. Always use static-dissipative packaging to protect displays from ESD.