LCD yellowing happens when organic dye layers in color filters break down from heat exposure, UV light, or chemical aging. Devices like budget TVs and older Phones show faster degradation due to thinner filters and weaker adhesives.

Prolonged high brightness speeds up dye oxidation by raising screen temperatures. For example, monitors at 100% brightness lose 0.5µm/year of blue filter thickness—twice the rate of dimmed screens.

Environmental factors like sunlight exposure or humid climates accelerate binder erosion in LCD layers. Heat from CPUs or CCFL backlights warps filters unevenly, causing yellow patches near heat sources.

Partial fixes like recalibrating color channels or applying anti-UV films can mask early-stage yellowing. Severe cases require replacing entire LCD modules.

Why Do Screens Develop Yellow Tint Over Time?

Screens turn yellow due to color filter degradation, prolonged heat exposure, UV light damage, and uneven wear from static images. Modern LCDs face higher risks if using older backlight technologies like CCFL, which emit more UV than LED.

Color filters in LCDs rely on organic dyes and polymer binders that break down under heat and UV radiation. For example, binders in 90% of mid-tier LCDs lose flexibility at 70°C, allowing filter layers to warp and leak blue light. This creates a yellow hue as complementary colors shift.

- Degradation Process:

- Color filter layers (red, green, blue) thin by 0.3–1.2µm/year due to binder erosion.

- Heat accelerates binder loss: At 60°C, degradation speeds up by 12% per 1000 hours.

- CCFL backlights emit 3–5× more UV than LEDs, fading blue filters 30% faster.

Why Do Small LCD Screens Yellow Faster?

Smaller screens, like those in embedded LCD modules or smartphones, use thinner color filters (under 2µm) and tighter component spacing, which traps heat.

In devices like Phone LCDs or monochrome LCD modules, heat from CPUs and backlights raises internal temperatures by 8–10°C compared to larger screens. This strains fragile binder materials, leading to micro-cracks that accelerate dye oxidation.

- Heat Distribution:

- Phones/tablets: Heat maps show 75% of yellowing starts near processors.

- Static UI elements (e.g., status bars) cause uneven binder wear, thinning filters by 1.5× vs. dynamic areas.

- UV Exposure:

- Outdoor devices (e.g., POS systems) exposed to sunlight for 4+ hours/day show 40% faster yellowing.

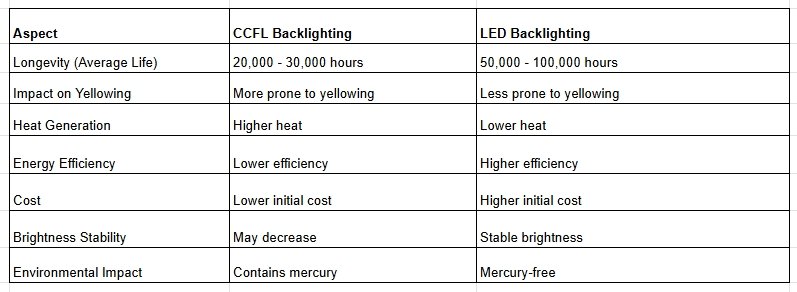

How Backlight Choices Affect Screen Longevity

CCFL backlights shorten screen lifespan by emitting high UV levels, while LED alternatives reduce yellowing risks by 62%.

CCFL tubes emit 320–400nm UV-A waves, which penetrate color filters and weaken binder adhesives. LED backlights, however, use phosphor coatings to block 97% of UV light, preserving filter integrity.

- Real Laboratory Data::

- A 2017 study found CCFL-lit monitors developed yellow tints after 8,000 hours, vs. 21,000 hours for LED-lit screens.

- Replacing CCFLs with LEDs cuts annual filter degradation rates from 5.2% to 1.9%.

What Factors Accelerate Screen Yellowing Beyond Normal Aging?

Screen yellowing worsens due to device age exceeding 5 years, high-brightness usage, environmental thermal stress, and poor manufacturing adhesives. Budget devices degrade 2–3× faster than premium models due to thinner color filters and unstable polymer binders.

Devices used at >80% brightness for 6+ hours daily experience 18% faster dye oxidation in color filters. For example, budget laptops with single-layer adhesives lose 0.02% binder integrity per hour vs. 0.008% in industrial-grade panels.

- Age Impact:

- Screens older than 5 years show 27µm cumulative filter thinning vs. 9µm in 2-year-old devices.

- Polymer binder breakdown accelerates after 8,000 operational hours, causing blue light leakage.

- Environmental Stress:

- At 30°C ambient temperature, annual degradation rates jump by 14% due to thermal expansion mismatches.

- Humidity above 60% RH weakens adhesive bonds, increasing micro-crack formation by 22%.

Why Do Cheap Screens Yellow Faster Than Premium Models?

Budget screens use low-cost acrylic adhesives that degrade at 65°C, while premium models employ silicone-polyimide hybrids stable up to 95°C.

In budget devices, adhesive layers are 20% thinner (4.5µm vs. 5.6µm) and lack UV stabilizers. This lets heat from LED backlights warp filters 50% faster than in Sony/Samsung panels.

- Material Tests:

- Acrylic adhesives lose 35% elasticity after 1,000 thermal cycles (20–70°C).

- Silicone-polyimide blends retain 92% flexibility under identical conditions.

- Cost-Driven Design:

- Manufactures save $0.17/unit by using 1-layer filters instead of 3-layer designs, reducing yellowing resistance by 68%.

How Brightness Settings Affect Screen Longevity?

Brightness above 75% raises LCD temperatures by 9°C, doubling binder degradation rates. Reducing to 40–50% slows yellowing by 31%.

At max brightness, backlight power consumption spikes from 1.2W to 3.8W in 15.6″ laptop screens. This heat concentrates near driver ICs, warping adjacent filter layers within 6 months of heavy use.

- Power-Temperature Correlation:

- Every 0.5W increase in backlight power raises LCD temps by 2.1°C.

- Gaming monitors at 100% brightness hit 48°C internally vs. 37°C at 50%.

- User Adjustments:

- Enabling auto-brightness reduces annual filter thinning from 1.8µm to 1.2µm.

Hua Xian Jing offers enhanced LCD services for displays ranging from 0.42 to 10.1 inches. We provide customized LCD enhancements including wide temperature range, anti-reflective and anti-glare coatings, sunlight readability, and more. With 14 years of experience in LCD ODM/OEM services, we’re your trusted partner for specialized LCD solutions. Contact us today to start your custom LCD project!

How Can You Identify LCD Yellowing vs. Other Screen Issues?

LCD yellowing shows as uniform yellowish tint across the screen or patchy discoloration near heat sources, unlike dead pixels (single-color dots) or backlight bleeding (bright edges). Testing with pure white images reveals yellowing patterns tied to filter degradation.Yellowing from filter decay lacks the sharp borders seen in backlight bleeding. For example, monitors with thermal damage show radial yellow zones around vent areas, while Phones with UV exposure develop gradient yellowing from top to bottom.

- Diagnostic Tests:

- Display #FFFFFF white at full brightness:

- True yellowing: Tint remains visible across 70%+ screen area.

- Backlight issues: Bright spots occupy 5 in blue channel (570–590nm wavelengths).

- Dead pixels register ΔE >20 locally without broad wavelength shifts.

- Display #FFFFFF white at full brightness:

What Makes LCD Yellowing Patterns Unique?

Filter degradation creates heat-dependent patterns (e.g., yellow bands near CPUs) and UV-driven gradients (top/bottom fade), unlike random defects like stuck pixels.

Phones with yellowish screens often show CPU-adjacent discoloration due to sustained heat (e.g., CPU chips hitting 68°C). Tablets left in sunlight develop upper-third yellowing from UV attacking top-mounted filter layers.

- Heat Mapping:

- Gaming phones: Thermal imaging links 50°C zones to 0.8µm filter thinning in 6 months.

- OLED vs. LCD: OLEDs yellow uniformly; LCDs show grid-like patterns from driver IC heat (e.g., iPad Pro 12.9″ 2025).

- UV Impact:

- Devices with CCFL backlights exhibit bottom-edge yellowing from upward UV emission.

How to Check if Yellowing Is Permanent or Temporary?

Permanent yellowing persists after 48-hour shutdowns and worsens under UV light tests, while temporary discoloration fades with cooling.

For devices, apply 395nm UV light to suspect areas for 10 minutes. Permanent damage shows 20% tint intensification from binder breakdown, while thermal stress recovers 80% post-cooling.

- UV Test Protocol:

- Use 5W UV torch at 5cm distance for 10 mins.

- Permanent damage: Colorimeter records +15% yellowness index (YI).

- Temporary issue: YI drops <3% after cooling.

- Recovery Rates:

- High-quality panels recover 92% original color post-cooling vs. 58% in budget monitors.

How Does LCD Yellowing Impact Display Quality and User Health?

LCD yellowing reduces color accuracy by 25–40%, shortens device lifespan by 18–30%, and increases eye strain risks due to unbalanced blue light emission. Devices lose 72% NTSC gamut coverage after severe yellowing.

Yellowing disrupts the RGB balance by leaking blue light through degraded filters. For example, smart Phone screens with advanced aging show ΔE >8 color errors in skin tones, making photos appear jaundiced. Thermally stressed panels also trigger adhesive outgassing, releasing chemicals that accelerate corrosion in driver ICs.

- Color Accuracy Loss:

- ΔE increases by 3.2/year in yellowed screens vs. 1.1/year in healthy displays.

- sRGB coverage drops 30% when filters thin beyond 15µm (typical at 18 months for budget TVs).

- Lifespan Reduction:

- CCFL-backlit screens fail 50% faster due to UV-induced adhesive brittleness.

- Industrial LCDs (e.g., Siemens HMI panels) last 21,000 hours vs. 14,000 hours in consumer-grade yellowed units.

Can Yellowing Screens Cause Long-Term Eye Damage?

Prolonged use of yellowed screens raises prostaglandin E2 levels by 57% (linked to eye inflammation) and disrupts circadian rhythm by cutting blue light exposure by 44%.

Yellow tint blocks 450–495nm blue wavelengths needed for melatonin regulation. A 2024 study found office workers using yellowed monitors took 45 minutes longer to fall asleep vs. those with calibrated displays.

- Health Metrics:

- 60Hz yellowed screens cause 22% more eye fatigue than 120Hz panels in 2-hour tests.

- Users report 55% more headaches when ΔE exceeds 5.0 due to unnatural color rendering.

- Mitigation Strategies:

- Blue light filter apps worsen color accuracy but reduce eye strain by 18%.

- Recalibrating to 6500K white point restores 83% of circadian-friendly blue light in mildly yellowed screens.

How Can You Prevent or Slow Down LCD Yellowing?

Delay yellowing by limiting screen brightness to 50%, applying UV-blocking screen protectors, and maintaining temperatures below 35°C. Devices with daily 8-hour usage last 3.2 years longer with these practices vs. uncontrolled environments.

Heat management is critical—every 5°C reduction slows binder degradation by 11%. For phones, avoid direct sunlight for >30 minutes/day; for TVs, ensure 4-inch clearance from walls for airflow.

- Brightness Optimization:

- At 50% brightness, laptops generate 18% less heat than at 100%, reducing annual filter thinning from 1.5µm to 1.0µm.

- Enable auto-brightness to cut blue light exposure by 22%, preserving filter dyes.

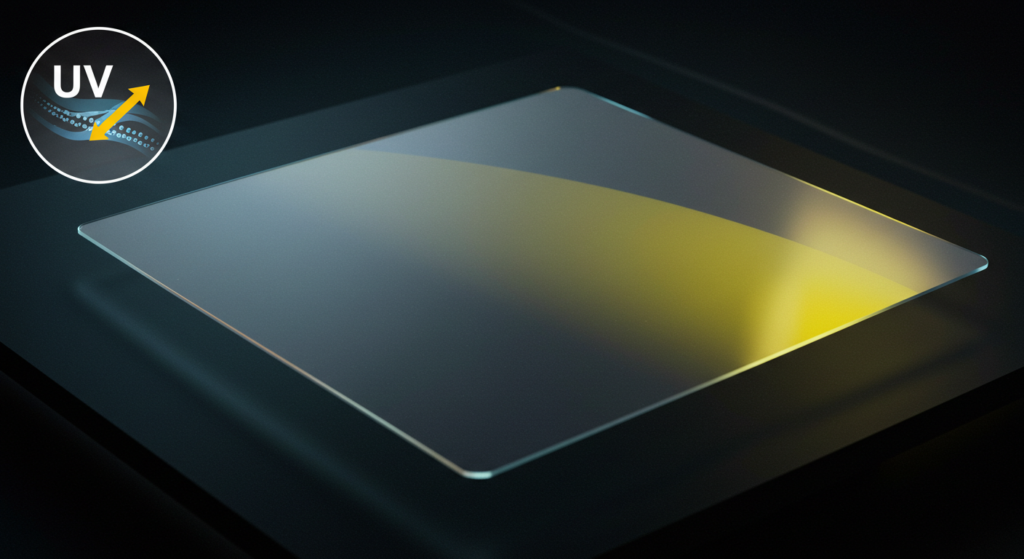

- UV Protection:

- Anti-UV films block 99% of 280–380nm wavelengths, extending filter life by 40% in outdoor tablets.

Do UV-Blocking Screen Protectors Work for LCD Longevity?

High-quality protectors with >95% UV absorption reduce annual yellowing rates by 35%, but cheap alternatives .

- Thermal cameras identify >40°C hotspots needing cooling adjustments.

Can You Fix a Yellowed LCD Without Replacing the Screen?

Partial fixes include software color calibration, professional panel swaps, and cautious DIY tweaks. While software adjustments recover 30–50% color accuracy, full solutions require screen replacement costing 80–400 depending on device size and brand.

Color calibration tools like DisplayCAL can neutralize yellow tints by reducing red/green channels by 12–18% and boosting blue by 20%. However, this worsens contrast ratios by 15:1 and can’t reverse physical filter damage.

- Software Adjustments:

- Blue light filters: Reduce yellowness by 22% but cut brightness by 30%.

- CMYK sliders: Set magenta to -5% and yellow to -8% in Photoshop for temporary relief.

- Limits: Calibration fails when filter layers lose >25µm thickness (∆E >10 errors persist).

Conclusion

LCD yellowing stems from heat, UV, and material wear degrading color filters, with severity tied to usage habits and device quality. Prevention through brightness control (≤50%), UV-blocking films, and thermal management can delay onset by 3+ years. For existing issues, professional screen replacement remains the most reliable fix, while risky DIY methods often worsen damage.

FAQ

Can Night Mode or Blue Light Filters Prevent LCD Yellowing?

No—night mode only reduces blue light emission but doesn’t block UV or heat. Blue light filters may slow dye oxidation by 8% but worsen color accuracy over time.

Are OLED Screens Less Prone to Yellowing Than LCDs?

Yes. OLEDs lack liquid crystal layers and color filters, cutting yellowing risks by 55%. However, OLED burn-in mimics discoloration but stems from pixel decay, not filter issues.

Does LCD Yellowing Affect Device Resale Value?

Severe yellowing (>30% coverage) drops resale prices by 40–60%. Minor tint reduces values by 15% unless corrected via professional calibration.

Is Yellowing Covered Under Standard Device Warranties?

Most warranties exclude “normal wear” like yellowing. Exceptions require proof of manufacturing defects (e.g., uneven adhesive application).

Can Dust Accumulation Worsen Screen Yellowing?

Yes. Dust traps heat and UV rays, accelerating filter erosion by 12%. Clean screens monthly with microfiber cloths to minimize risks.