Why Do LCDs Use AC Instead of DC?

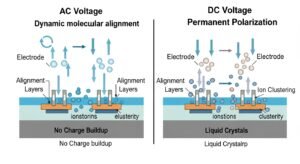

LCDs use AC voltage to prevent permanent polarization and protect liquid crystal molecules from degradation.

LCDs use AC voltage to prevent permanent polarization and protect liquid crystal molecules from degradation.

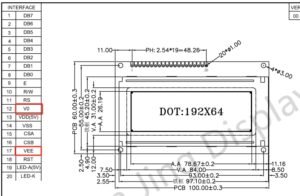

Some LCD modules need a negative voltage on the VEE pin to set the liquid crystal cell at a mid bias.

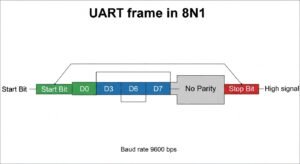

Correct wiring connects the microcontroller’s TX pin to the LCD’s RX pin, RX to TX, and a shared ground to enable serial communication.

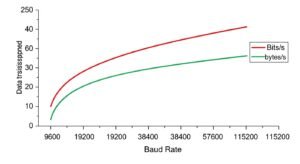

Baud rate controls how fast data reaches monochrome LCDs. Higher baud rates speed up display updates but risk transmission errors.

Built-in LCD controllers sit on the display module or main board with dedicated VRAM and optimized firmware.

The rise and fall times on the enable pin decide if the LCD1602 can read data without mistakes.

A timing controller, or TCON, makes sure each pixel in an LCD gets the right signal at the right time.

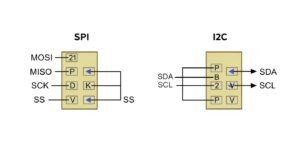

SPI uses four wires—MOSI, MISO, SCK, and SS—needing more pins. I2C needs only two wires, SDA and SCL, saving space.

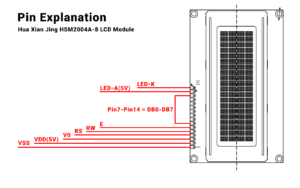

In 4-bit mode, the LCD uses four data lines to send data in two parts, saving pins but taking more time. In 8-bit mode, it uses eight data lines to send data all at once, speeding things up but needing more pins.

Most character LCDs use the Hitachi HD44780 or compatible clones like AIP31066 or SPLC780. These share a standard 14/16-pin layout for easy wiring.

Download our comprehensive catalog to explore 10,000+ LCD module options in detail:

0.42-10.11 inch TFT LCD

16×2-320×240 COB LCD

8×2-320×240 COG LCD