Struggling to choose the right display for your product? The wrong choice can lead to high costs and poor user experience.

Segment LCDs display fixed, pre-defined patterns, like numbers on a calculator. Dot matrix LCDs use a grid of pixels to show various graphics and text, offering much more flexibility.

How Do Segment LCD and Dot Matrix LCD Structures Differ?

The way these displays are built fundamentally separates them. This internal structure is the reason for all their other differences in features, cost, and application.

A segment LCD has a structure of pre-designed electrodes that form specific shapes. A dot matrix LCD has a grid of individual dots, or pixels, arranged in rows and columns.

To really get it, you have to think about what you want to show. Are you displaying the same information all the time, or does it need to change?

The Segment LCD Structure

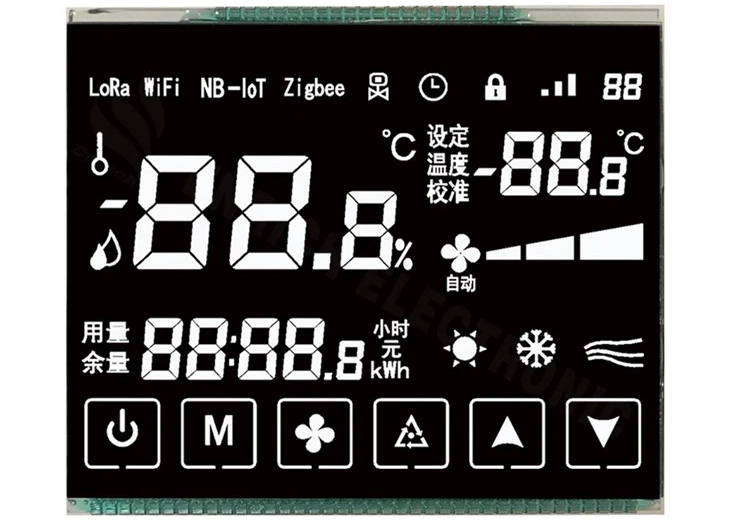

Think of a digital alarm clock. The numbers are always in the same spot, made of seven segments. Each segment is a separate electrode. We design these electrodes into any shape you need—numbers, letters, icons like a battery symbol, you name it. When we apply voltage to specific segments, they become visible. It’s simple and effective. The layout is permanent, so you have to decide on the design from the start. This involves a one-time tooling fee to create the custom glass mask(How to Design Your Own Segment LCD?).

Here are some examples of what can be designed as a fixed segment:

| Icon Type | Common Use | Complexity |

|---|---|---|

| Numeric Digits | Clocks, meters, calculators | Low |

| Battery Indicator | Mobile devices, power tools | Low |

| Wi-Fi Symbol | IoT devices, routers | Low |

| Custom Logos | Branded products | Medium |

The Dot Matrix LCD Structure

Now, imagine a tiny grid of dots. This is a dot matrix display. Each dot is a pixel that can be turned on or off independently. By controlling which pixels are on, you can create any character, number, or simple graphic you want. These displays are organized by rows and columns. For example, a 128×64 display has 128 columns and 64 rows of alphanumerics. This structure makes them incredibly versatile. You don’t need custom tooling for the display content itself, because the pixel grid is standard.

What Are the Features of Each Display Type?

The structure of each display directly leads to its unique set of features. One focuses on efficiency and clarity for specific tasks, while the other offers flexibility for dynamic content.

Segment displays offer high contrast and very low power consumption for showing fixed information. Dot matrix displays are valued for their ability to show graphics, multiple fonts, and dynamic data.

Feature Comparison

| Feature | Segment LCD | Dot Matrix LCD |

|---|---|---|

| Display Content | Fixed icons, numbers, symbols | Graphics, text, patterns |

| Flexibility | Low (content is permanent) | High (content is dynamic) |

| Customization | High (shape/layout is custom) | Low (pixel grid is standard) |

| Contrast Ratio | Very High | Good to High |

| Viewing Angle | Very Wide | Good |

| Power Consumption | Extremely Low | Low to Medium |

| Tooling Cost (NRE) | Required for custom designs | None for display content |

| Unit Cost | Lower | Higher |

Segment LCD

The biggest feature of a segment LCD is its simplicity. Because the segments are large and dedicated to one shape, the contrast is fantastic. The characters are crisp and easy to read from a distance and at wide angles. They are also incredibly reliable and durable, which is why you see them in industrial meters and medical devices that need to last for years.

Dot Matrix LCD

The key feature here is versatility. You are not locked into a fixed design. You can display scrolling text, show simple animations, or support multiple languages by simply changing the software. This is impossible with a segment display. Dot matrix displays, especially graphic types, can show much more information at once, making them suitable for interfaces that require menus or detailed status updates.

How Do Power Consumption and Cost Compare?

For any project, especially battery-powered ones, power and cost are critical decision factors. This is where the two display types differ the most, and it’s often the deciding factor.

Segment LCDs are the champions of low power and low cost. They use significantly less energy and have a lower unit price compared to dot matrix displays of a similar size.

I once worked with an engineer on a handheld water quality meter. Battery life was his number one concern. We immediately focused on segment LCDs.

Power Consumption Analysis

A segment LCD consumes microamps (μA) of current. This is because the driver only needs to apply voltage to a few segments at a time. It’s a very efficient process. You can often run a device with a segment display for years on a single coin cell battery.

A dot matrix display, on the other hand, needs to constantly refresh its entire grid of pixels, even the ones that are off. This requires more processing and more power, typically in the milliamps (mA) range—that’s a thousand times more than a segment display. This makes them less ideal for devices that need to conserve power over long periods(What Is the Right Way to Use Level Shifters With 3.3V LCD Modules in 5V Systems?).

Cost Breakdown

There are two types of costs to consider: the one-time tooling cost and the per-unit cost.

- Tooling Cost (NRE): For a custom segment LCD, you have to pay a one-time Non-Recurring Engineering (NRE) fee. This is for creating the photolithography masks that define your unique segment layout. This can be a few thousand dollars. Dot matrix displays usually have no NRE because the pixel layout is standard.

- Unit Cost: Once the tooling is paid for, the price per segment display is very low. Dot matrix displays are more complex to manufacture, with more connections and often an integrated controller IC, so their unit price is higher.

For the multimeter, a custom segment display was perfect. The initial tooling cost was acceptable because he planned a large production run, and the low unit cost and minimal power draw were exactly what he needed.

Which Applications Are Best Suited for Each Display?

Understanding the structure, features, and costs leads us to the final question: where should you use them? The application will always dictate the best choice.

Use segment LCDs for products that display simple, repetitive information like numbers or status icons. Choose dot matrix LCDs for devices that require graphical interfaces or flexible text displays.

Matching the display to the application is my favorite part of the job. It’s like solving a puzzle.

Common Applications for Segment LCDs

These are ideal for “set it and forget it” information displays. The user just needs to glance at it and get a clear reading.

- Digital clocks and watches

- Calculators

- Utility meters (water, gas, electric)

- Medical devices (glucose meters, thermometers)

- Appliance displays (microwaves, washing machines)

- Industrial Meter

- UPS Device

Common Applications for Dot Matrix LCDs

These are used when the information is more complex or needs to change. They are better for interactive devices.

- Point-of-Sale (POS) terminals

- Medical equipment with menus (infusion pumps)

- Industrial controllers that show graphs or logs

- Handheld measurement tools with advanced functions

- Vending machine interfaces

- Printers and network equipment

For a client making an assembly line controller that needs to display error messages in multiple languages, a dot matrix display is the only logical choice. For a simple thermostat showing the temperature, a segment display is cheaper, clearer, and more power-efficient.

How to Drive Them?

Controlling the display, or “driving” it, is the final technical piece of the puzzle. The method is very different for each type and impacts your circuit and software design.

Segment LCDs are driven by applying specific AC voltages to segment and common pins, often with a simple driver IC. Dot matrix displays require a more complex controller that manages a memory map of all pixels.

This topic can get very technical, but I’ll explain it in a practical way.

Driving a Segment LCD

You can’t just connect a segment pin to a DC voltage. LCDs require an AC signal to prevent electrochemical degradation of the liquid crystal material. The display has “segment” pins and “common” pins. The segments you want to turn on get a waveform that is out of phase with the common pin’s waveform. Segments you want to leave off get a waveform that is in phase.

There are two main methods:

- Static Drive: Each segment has its own dedicated driver pin. This is simple but uses a lot of microcontroller pins. It’s only for displays with very few segments.

- Multiplex Drive: Segments are grouped and driven in a sequence. This uses fewer pins but slightly reduces contrast and viewing angle. This is the most common method(What Is the Purpose of Multiplexing in LCDs?).

Many microcontrollers have built-in LCD drivers that handle all of this for you, making it very easy to implement.

Driving a Dot Matrix LCD

Driving hundreds or thousands of individual pixels is too complex for a standard microcontroller. That’s why dot matrix modules almost always come with a controller IC already on the board.

This controller IC does all the heavy lifting. It has its own RAM (a framebuffer) that stores the state of every pixel. Your microcontroller just sends high-level commands to the controller, like “draw a character at this position” or “set this pixel to on.” Common communication interfaces like I2C, SPI, or a parallel bus are used to talk to the controller. This makes the software side easier in some ways, but the initial setup and communication protocol are more complex than for a segment display.

Conclusion

The choice between segment and dot matrix LCDs depends entirely on your application’s needs. One offers unmatched efficiency for fixed data, the other provides flexibility for dynamic content.

FAQ

Can I customize the display shapes in both segment and dot matrix LCDs?

You can customize segment LCD shapes during design and production. Dot matrix LCDs allow flexible content customization through software.

Can Segment LCDs Display Graphics Like Dot Matrix LCDs?

Segment LCDs cannot display complex graphics. Their fixed segments limit them to predefined patterns, unlike the flexible pixel grids of dot matrix LCDs.

Are Segment LCDs More Durable Than Dot Matrix LCDs?

Segment LCDs are often more durable. Their simpler design withstands harsh environments better than the more complex dot matrix LCDs.

Do Dot Matrix LCDs Support Color Displays?

Some dot matrix LCDs support color with advanced configurations. Segment LCDs typically remain monochrome due to their fixed segment design.

What is the typical lifespan of segment and dot matrix LCDs?

Both types generally last over 50,000-100,000 hours if used within recommended temperature and voltage ranges.