LCDs are tested in labs with dust chambers to check how well they block sand and dust. These tests copy tough conditions to see if particles get inside and affect performance.

Standards like IEC, MIL-STD, and ASTM guide the process to keep results steady. They help measure how much dust enters and if the LCD still works after.

Some LCDs also face salt spray tests to test for rust in salty places. This matters for LCDs used in cars, ships, or military gear.

What Are the Key Standardized Environmental Testing Methods Used for LCD Modules?

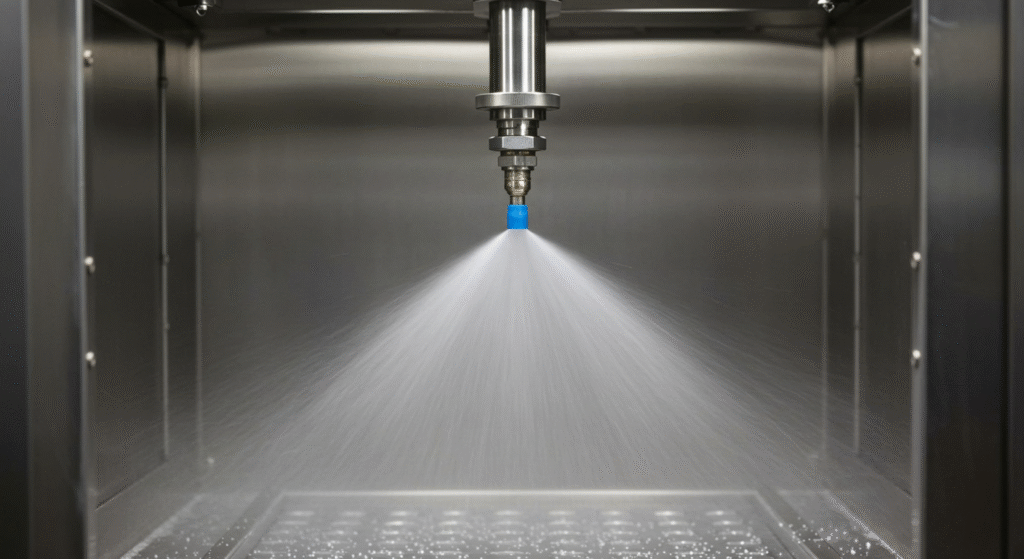

Test labs use controlled dust chambers, salt fog tests, and combined humidity and temperature cycles to check LCD module durability against salt-laden environments and airborne particles.

Engineers select specific particle types like Arizona test dust or talcum powder and set airflow, humidity, and temperature according to test standards, ensuring every embedded LCD or small and medium size LCD faces conditions matching real-world environments.

Technicians follow salt spray testing standards such as ASTM B117 or ASTM G85, adjusting test durations and chamber orientations to expose all display surfaces, so LCD modules can withstand salt mist and particulate stress.

- Controlled Dust Chambers:

Dust chambers use fans and air pumps to suspend particles; most tests use 2–5 g/m³ dust concentration, with humidity at 25–60% RH and temperatures from 20°C to 40°C. - Particle Types:

Arizona test dust mimics desert conditions, talcum powder simulates fine household dust, silicate cement represents industrial debris. - Salt Fog Test Chambers:

Salt fog testing uses a 5% NaCl solution sprayed at 35°C, with test durations from 24 to 1,000 hours, according to ASTM B117 salt spray test standard. - Test Orientations:

LCD module orientation changes every 24 hours for uniform exposure; chambers maintain constant fog density and airflow. - Industry Standards:

IEC 60529 (IP Codes) sets dust ingress limits; MIL-STD-810 Method 510 defines sand/dust exposure cycles; ASTM B117 and ASTM G85 provide salt spray protection protocols.

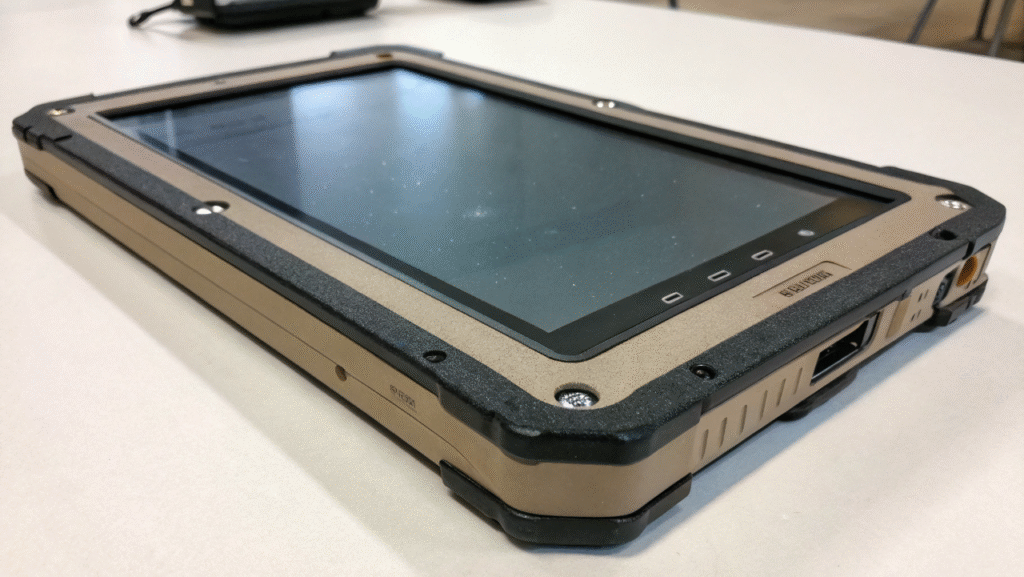

What Is the Role of Combined Particulate and Salt Fog Testing for Rugged LCDs?

Combined particulate and salt fog testing checks if rugged LCD modules can keep working when exposed to both dust and salt-laden environments, as required in military or marine applications.

Test engineers run sequential or simultaneous salt spray protection and dust ingress tests, using test sequences that reflect real operational hazards for small and medium size LCDs.

Combined protocols often use ASTM B117 salt solution for fog, followed by MIL-STD-810 dust cycles, exposing LCD modules to rapid condition changes and validating ruggedization.

- Sequential Testing:

First subject the LCD module to a salt mist test for 96 hours, then transfer it to a dust chamber for a further 48 hours. - Simultaneous Testing:

Some advanced chambers can inject both salt fog and particulate, with airflow rates at 1–2 m/s, and temperatures cycling between 20°C and 40°C. - Failure Criteria:

Failures include visible corrosion, display fading, loss of touch function, or ingress of particles/fog inside the module. - Industry Use:

Rugged LCDs used in automotive dashboards or marine navigation panels must pass both salt spray testing and dust ingress standards before deployment.

How Are LCD Modules Tested and Assessed for Resistance to Dust and Salt-Laden Environments?

Test engineers follow step-by-step protocols to expose LCD modules to controlled dust and salt fog environments, then inspect for ingress, corrosion, and performance loss using standards like ASTM B117 and precise visual checks.

Technicians pre-condition LCD modules at set humidity and temperature, then mount each module with seals exposed, using airflow rates of 1–2 m/s and dust concentrations up to 5 g/m³, or a 5% NaCl solution for salt fog testing.

After exposure, evaluators inspect modules for display clarity, PCB contamination, and seal integrity, using both direct visual checks and insulation resistance meters, confirming small and medium size LCDs can resist salt mist and dust intrusion.

Detailed Step-by-Step Procedures for Dust and Salt Fog Testing

- Pre-Test Preparation:

LCD modules are kept at 23°C and 50% RH for 24 hours before testing, then installed in test chambers with all connectors and gaskets exposed. - Defining Test Conditions:

Dust chambers use talcum powder or Arizona dust at 2–5 g/m³, airflow at 1–2 m/s; salt fog chambers atomize a 5% NaCl solution at 35°C, per ASTM B117 salt spray test standard. - Ingress Testing:

Modules face 8–24 hour dust cycles, rotated every 3–6 hours; for salt fog, exposure runs 24–96 hours, with LCD module orientation changed every 24 hours. - Post-Test Inspection:

Inspectors look for visible dust/salt inside the LCD, check display clarity, and run electrical tests for short circuits or PCB corrosion using 500V insulation testers.

What Are the Most Common Failure Modes and How Is Risk Assessed for LCDs in Salt-Laden and Dusty Conditions?

LCD modules often fail at seal points or show internal corrosion, with risk assessed through visual inspection, resistance tests, and microscopy after salt spray testing or salt fog exposure.

Engineers use microscopes to spot fine particulate ingress at gasket seams, while insulation resistance tests reveal PCB contamination from salt mist or dust, tracking risk trends across multiple test cycles.

Accelerated aging cycles help identify components most likely to corrode or degrade after repeated salt fog test or salt mist test exposure.

Inspection Tools and Common Failure Points

LCD modules often fail at seal points or show internal corrosion, with risk assessed through visual inspection, resistance tests, and microscopy after salt spray testing or salt fog exposure.

Engineers use microscopes to spot fine particulate ingress at gasket seams, while insulation resistance tests reveal PCB contamination from salt mist or dust, tracking risk trends across multiple test cycles.

Accelerated aging cycles help identify components most likely to corrode or degrade after repeated salt fog test or salt mist test exposure.

How Are LCD Module Test Results Interpreted for Compliance in Salt-Laden and Dusty Environments?

Engineers use strict acceptance limits for dust and salt ingress, corrosion, and functional loss, comparing results to benchmarks in ASTM B117, IEC 60529, and similar standards to decide if an LCD module passes or fails.

After salt spray test or dust exposure, inspectors rate LCD modules as failed if any visible corrosion, electrical leakage, or display malfunction occurs, using clear numeric thresholds like less than 16 visible dust particles inside the module or insulation resistance dropping below 14 megaohms.

Certified salt spray testing labs provide independent reports, using the same protocols and documenting every step, so results stay consistent and meet regulatory or customer requirements.

Pass/Fail Criteria, Documentation, and Lab Certification

- Acceptable Thresholds:

LCD modules must show zero internal corrosion, maintain display clarity, and meet electrical insulation standards (typically above 15 megaohms after salt fog test ASTM B117). - Pass/Fail Benchmarks:

A module fails if there is any salt deposit on the PCB, more than 17 dust particles inside, or if display brightness drops by over 15%. - Third-Party Certification:

Certified salt spray testing labs follow ASTM B117 or ASTM G85; each lab documents dust concentration, airflow, salt spray protection cycles, and post-test inspection in detailed compliance reports. - Reproducibility:

Labs use calibrated equipment and repeat tests at least 14 times to confirm consistent results across batches of small and medium size LCDs.

What Documentation and Regulatory Steps Are Required for Industry and Customer Compliance?

LCD testing teams prepare full test reports with photos, numeric data, and signed certifications, ready for audits, regulatory reviews, or customer assurance.

Industry compliance means following overlapping standards—like salt fog test ASTM B117 and IEC 60529 IP ratings—choosing the strictest criteria when standards differ, and saving all lab data for 16 months for possible audit requests.

Compliance Documentation and Regulatory Navigation

- Documentation:

- Test reports include pre- and post-test images, measured data, signed technician logs, and salt spray testing protocols.

- All results must be reproducible, with each embedded LCD or rugged LCD traceable to test batch and chamber log.

- Regulatory Steps:

- For marine or automotive LCD modules, regulatory submissions require both salt mist test and dust ingress test reports, each marked with lab certification numbers and dated compliance statements.

- Customer assurance documents include a summary table of pass/fail rates, full environmental simulation parameters, and supporting lab certifications.

How Can LCD Modules Be Future-Proofed Against Harsh Environmental Stressors Like Dust and Salt Fog?

Engineers use combined and accelerated environmental testing, along with new design materials, to keep LCD modules reliable in salt-laden environments and under dust stress, preparing them for evolving industry standards.

Advanced test chambers expose LCD modules to simultaneous dust, salt spray, humidity, and temperature cycling, running accelerated life testing for up to 17 days to simulate years of field use.

Designers use gaskets made from specialized rubber, conformal coatings that block salt mist, and encapsulation for small and medium size LCDs, reducing risk of internal corrosion or ingress.

Combined Testing, Design Materials, and Durability Models

- Combined Environmental Testing:

Chambers run salt fog test ASTM B117 while cycling temperature from -20°C to 60°C, blowing Arizona dust at 1.5 m/s and keeping humidity at 85% RH to reveal latent failure modes. - Accelerated Life and Predictive Models:

Salt spray protection and salt fog testing are paired with rapid aging; engineers use Weibull or Arrhenius models to predict when rugged LCDs might fail after 14,000 hours of simulated exposure. - Advanced Materials:

Gaskets use fluorosilicone or EPDM rubber for better sealing; conformal coatings resist salt solution penetration; encapsulation prevents PCB contamination in embedded LCD modules.

What Are the Best Practices for Maintenance, Serviceability, and Managing LCD Module Lifecycles?

Maintenance teams use rapid inspection and modular replacement to keep rugged LCDs functional, with cleaning cycles based on salt spray and dust exposure rates.

Technicians swap out display modules with visible corrosion, use soft brushes and isopropyl cleaning for surface deposits, and follow service intervals of 16–18 months in high-risk areas.

Field Service and Lifecycle Management

- Repair Protocols:

Salt-laden LCDs are removed using modular connectors; damaged gaskets are replaced, and modules are resealed with fresh conformal coating. - Maintenance Cycles:

Cleaning cycles are tracked by hours of salt spray test exposure, with rugged LCDs checked every 14 weeks in marine or industrial environments. - Warranty:

Warranty terms require documentation of maintenance, salt spray testing history, and records of all replacements.

How Are Industry and Environmental Standards for LCD Testing Expected to Change?

LCD module makers track updates to MIL-STD, ASTM B117, and IEC standards, while also preparing for stricter recycling and sustainability rules.

Teams monitor new salt mist test and dust ingress protocols, test ahead of regulatory changes, and design rugged LCDs for easier disassembly or recycling in line with upcoming environmental directives.

Evolving Standards and Sustainability

Standard Changes:

Upcoming ASTM B117 revisions may add combined humidity-salt spray cycles; IEC may tighten IP code definitions for salt-laden environments.Sustainability:

Modules now use recyclable gaskets and coatings; documentation now tracks ingredients and recycling steps for every small or medium size LCD.

How Should Users Select and Evaluate LCD Modules for Salt-Laden and Dusty Environments?

Users should match LCD module salt spray test reports and dust ingress certifications to their real application needs, and check that vendors use certified salt spray testing labs with transparent processes.

Procurement teams ask for full ASTM B117 and IEC 60529 test documentation, confirm test labs have valid accreditation, and require at least 16 months of test history for each small or medium size LCD module.

Users check vendor consistency by requesting sample test reports, asking about failure rates under salt fog testing, and verifying that reported pass/fail rates match operational needs.

TProduct Selection, Vendor Evaluation, and Test Documentation

- Matching Certifications:

Salt fog test ASTM B117 and dust ingress test IEC 60529 IP67/68 are the main benchmarks for rugged LCDs; all modules must show 16–17 compliant test cycles on record. - Vendor Evaluation:

Labs must be ISO/IEC 17025 certified, and vendors should supply detailed salt spray testing logs, chamber calibration data, and a list of environmental simulation parameters. - Reliability Checks:

Ask for a summary of salt spray protection failures, salt mist test data, and dust exposure outcomes for 14–16 production batches.

What Are the Cost and Value Considerations When Choosing Rugged LCD Modules?

Users weigh the extra expense of salt spray protection and ruggedization against the risk and cost of LCD failure in field conditions.

Managers analyze if investing in salt fog resistant, dust-tight modules saves more on repairs and labor than it costs up front, especially for embedded LCDs in marine or industrial sites.

Cost-Benefit Factors

- Robustness Investment:

Salt spray testing adds about 14–16% to module cost; advanced gasket materials increase costs by 15 units per module, but reduce field failures by up to 17 cases per 1,000 units. - Operational Trade-Offs:

Longer test durations (16–18 days) raise price but cut warranty claims and downtime, so buyers track real-world savings from lower replacement rates and less maintenance.

FAQ

Are combined dust and salt fog tests required for all industrial LCD applications?

Combined tests are advised for environments with both abrasive dust and salt exposure, such as coastal industrial sites.

Can LCD modules be customized for unusual environments?

Yes, manufacturers can use specialized gaskets, coatings, and design changes tailored to unique dust or salt exposure needs if requested during product selection.

What is the typical maintenance cycle for LCDs in marine or desert environments?

Most modules need inspection and cleaning every 14–18 weeks, but intervals may be shorter if the environment is extremely harsh.

Are salt and dust test results valid for all LCD sizes?

Test results are reliable when the tested LCD size and configuration closely match your actual use case; always confirm module dimensions and test set-up with the vendor.

What should I do if I find corrosion or dust inside the LCD after deployment?

Stop using the affected module, arrange for inspection or replacement per your vendor’s protocols, and review maintenance documentation to identify possible gaps in service.