LCD power consumption in an embedded system can be reduced by turning the screen off when possible and dimming the backlight. It also helps to adjust the display settings for efficiency and choose components designed for low power.(What Are the Differences Between VCC, VDD, VSS, and VEE in LCD Power Inputs?)

Low power design in embedded systems focuses on minimizing each component’s energy use. This means even the LCD is only active when necessary.

Adjusting an embedded LCD’s parameters can reduce its power usage. For example, using a lower refresh rate or resolution means the display does less work and draws less energy.

Power gating is a way to shut the display off completely when it is not needed. This technique ensures no energy is wasted by the LCD during idle periods.

The backlight often uses more power than the LCD panel itself. Dimming it or turning it off when possible leads to significant energy savings.

Selecting display components with low power consumption can greatly reduce the system’s energy use. For example, a simple monochrome LCD will draw much less power than a large full-color screen.

How does an embedded LCD consume power?

Embedded LCD panels consume power primarily by charging and discharging their segment capacitances and by powering any backlight. The LCD glass itself draws virtually no direct current, whereas an LED backlight (if present) can use far more power.

AC Drive and Segment Switching

AC drive waveform for an LCD segment (selected vs. non-selected). The average voltage over a cycle is zero, so there is no DC bias on the liquid crystal.

An embedded LCD is driven with an alternating voltage rather than DC. A constant DC voltage would damage the liquid crystal, so the drive signals continuously flip polarity. As a result, each LCD segment behaves like a small capacitor being charged and discharged. There is essentially no continuous current flowing through the liquid crystal itself. Power is only drawn when the segment’s electric field is switched, which means the panel’s intrinsic consumption is extremely low. In practice this leads to very low power consumption for the LCD glass – often just a few microamps for an entire display.

Dynamic Power in LCD Segments

Because each segment is capacitive, the energy use follows the dynamic power formula P = C·V²·f. The power to drive a segment depends on its capacitance (C), the driving voltage (V), and the frequency of the AC waveform (f). In an embedded LCD the AC drive frequency is kept low – typically on the order of tens of hertz (e.g. ~30–100 Hz) – to save energy while avoiding flicker. Higher refresh rates or larger LCDs (with more segment capacitance) will linearly increase the power consumption. Similarly, running at a higher LCD drive voltage greatly raises the power use (since it scales with V²): for example, using 5 V instead of 3.3 V more than doubles the segment power draw. However, even under worst-case conditions, the segment-driving part of an LCD is very efficient. Only the changing electric field uses power, so if a segment’s state isn’t toggling, it draws almost no current. In one low power design, a watch display’s LCD controller drew ~3 µA with all segments off and ~4 µA with all segments on. This tiny consumption is why simple monochrome LCDs are favored for battery-operated devices.

Backlight Power vs. Segment Power

If the LCD has a backlight, the backlight power can dominate the overall consumption.(How Do TN, IPS, and VA LCD Panels Affect Backlighting System Design?) The segments themselves might only draw microamps, but an LED backlight often draws milliamps of current – orders of magnitude more. For example, adding an LED backlight to a small segment LCD can increase the required current by up to ten-fold. In real-world designs, a bright backlight can easily draw tens of mA (e.g. 15 mA × 4 LEDs ≈ 60 mA) if left on continuously. This is far above the microamp-level current needed for the LCD segments. Consequently, the backlight is usually the primary consideration in low power design for embedded displays. Many low-power devices use reflective or transflective LCDs that are readable in ambient light, so that the backlight can be used sparingly. Techniques like briefly enabling the light on a button press, dimming via PWM, or using a more efficient LED can drastically reduce the backlight’s energy impact. In short, the liquid crystal itself only requires an electric field (minimal power), while lighting the display for visibility can cost much more energy.

Technical Details and Typical Values

Factors Affecting Backlight Power Consumption

- AC drive frequency: Common LCD drive waveforms range roughly from 30 Hz up to a few hundred hertz (often around 50–64 Hz). Lower frequencies minimize power use but must stay high enough to prevent flicker.

- Segment capacitance: Each segment electrode is a tiny capacitor (with the backplane as the other plate). Capacitances are on the order of tens of picofarads, depending on segment size and LCD technology.

- LCD drive voltage: Usually around 3 V in portable low power consumption applications, sometimes up to 5 V for higher contrast or wide-temperature operation. (Higher bias voltages increase power usage quadratically.)

- Segment current draw: On the order of microamps. A small static segment LCD panel typically draws ~1–5 µA in total when active. This current comes from continually charging the segment capacitors each frame.

- Backlight current draw: Often on the order of milliamps. Even a modest LED backlight can draw 10–20 mA, and multiple LEDs or higher brightness can draw tens of milliamps (vastly more than the LCD itself).

- Multiplexing levels: Using multiple common backplanes (multiplex drive) reduces pin count but can slightly increase current per segment. Higher multiplex ratios drive more segments per frame, raising the effective switching frequency seen by each segment and therefore using a bit more power.

Aside from the obvious brightness setting, several factors influence how much power a backlight draws:

- Number of LEDs: Backlights with more LED elements (or larger LEDs) will consume more power. A bigger display that uses multiple LEDs will draw proportionally more current than a single-LED backlight.

- LED efficiency: The efficacy of the LED (light output per unit of power) matters. New high-efficiency LEDs can achieve the same brightness at a lower current. Choosing LEDs with higher luminous efficiency reduces the required drive current for a given illumination level.

- Optical design (transflective vs. transmissive): A display with a transflective polarizer can use ambient light to make the content visible, reducing reliance on the backlight. Good optical coupling (efficient light guides and reflectors) ensures that more LED light reaches the viewer, meaning the backlight can be run at a lower power for the same readability.

- Driver circuitry: The way the LED is driven affects power loss. Using a dedicated LED driver (or a boost converter with current regulation) can deliver the needed LED current more efficiently than a simple resistor drop. An efficient driver minimizes wasted energy, especially if the supply voltage is higher than the LED’s forward voltage.

- Duty cycle of use: Limiting how long the backlight stays on significantly lowers energy use. For example, briefly lighting the backlight on user interaction, or using PWM to dim it, cuts down the average power. By minimizing the backlight’s active time, designers prevent it from draining the battery unnecessarily while still providing on-demand visibility.

Which LCD drive settings reduce power consumption the most?

Lowering the LCD’s drive voltage, reducing the refresh frequency, and minimizing the display’s effective capacitance are the most effective ways to cut its power use. These three adjustments each target one term of the dynamic power equation (P ≈ C·V²·f), so changing any of them directly reduces the LCD’s energy consumption.

In an embedded low-power design, the display’s power draw is almost entirely dynamic – each segment acts like a small capacitor being charged and discharged continuously. The power required is proportional to the capacitance of the LCD, the square of the drive voltage, and the refresh frequency of the drive waveform. Effective power management in embedded systems therefore focuses on optimizing these three parameters (C, V, and f) within the constraints of the application.

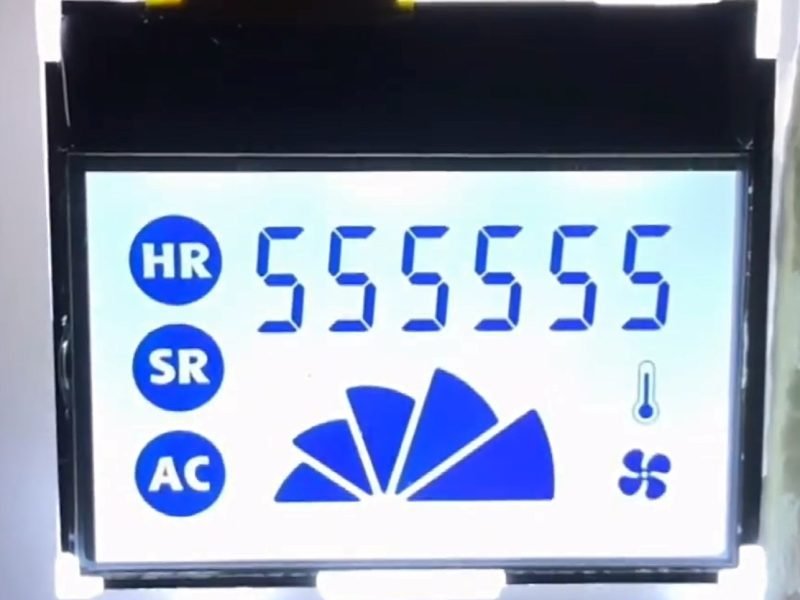

A custom segmented LCD module, consisting of seven-segment numerals and a bar graph, used in battery-powered devices. Such static drive displays draw only microamp-level currents by using reflective segments and efficient AC drive waveforms (no LED backlight).

- Capacitance (C): The LCD’s inherent capacitance is set by its size, technology, and connections. Each segment’s area and the wiring to it determine the capacitive load that must be driven. While this display capacitance is largely fixed by the hardware, designers can minimize parasitic capacitance in the interconnects – for example, by placing the LCD driver as close as possible to the glass to shorten traces. A smaller or simpler display (fewer segments, or smaller segment area) will naturally have less C and thus use less power, though the trade-off is reduced information display or readability. (There is an obvious limit here: making the screen too small or sparse harms usability.) Additionally, using a static drive (one dedicated pin per segment) instead of a multiplexed drive can avoid extra switching overhead. In a multiplexed LCD, segment lines are shared and driven in groups, requiring multiple voltage levels and more frequent transitions; this adds to effective capacitance and often wastes energy in bias networks. A static (direct-drive) configuration eliminates those losses – no divider networks are needed – making it more efficient at the cost of using more microcontroller pins.

- Drive Voltage (V): Lowering the LCD’s drive voltage yields a quadratic reduction in power consumption (since power scales with V²). Using the lowest LCD bias voltage that still produces a readable contrast can dramatically save energy. Many simple low-power IoT microcontrollers allow running the LCD at 3.3 V drive instead of a 5 V drive; this nearly halves the voltage and can cut the LCD’s current draw by about (3.3/5)² ≈ 44%. The challenge is that the voltage cannot go below the LCD contrast threshold. Each LCD fluid has a minimum RMS voltage needed to turn segments fully “on” versus “off” – if the drive voltage is too low, the segments will appear dim or indistinct. For example, at colder temperatures the liquid crystal becomes less responsive, and a higher voltage is required to maintain the same contrast. Engineers must therefore pick a voltage high enough for clear contrast under worst-case conditions (temperature, viewing angle, etc.), but no higher than necessary. Some power management in embedded systems involves using temperature compensation: e.g. increasing V slightly in the cold, but reducing it at room temperature to save power. It’s also common for LCD driver modules to include an internal charge pump that generates a boosted drive voltage when the desired contrast voltage exceeds the battery voltage. Any inefficiency in this charge pump will add to power loss, so a design that avoids using a high bias voltage (or uses a very efficient charge pump only when needed) will conserve more energy. In practice, the best approach is to use the lowest drive voltage that meets the contrast requirements of the application, nothing more.

- Refresh Frequency (f): The LCD is driven by an AC waveform that periodically reverses polarity (to avoid DC bias on the segments). The frequency of this drive can often be adjusted, and lowering it will linearly decrease the power drawn. However, there is a hard limit: if the refresh frequency is too low, the display will start to flicker visibly and become uncomfortable to read. Most embedded LCD drivers use a frequency in the range of roughly 30 Hz to 100 Hz. Below about ~30 Hz, the human eye can detect flicker as the segments flash on and off, especially in certain lighting conditions. On the other hand, driving the LCD at very high frequencies provides no visual benefit – the liquid crystals cannot switch infinitely fast, and once you are above the flicker fusion threshold, the image looks steady. Thus, the optimal choice is usually the lowest frequency that still avoids any perceptible flicker. For example, many battery-operated clocks and sensors drive the LCD at around 50–60 Hz (often derived from a 32 kHz watch crystal divided down) as a compromise between low power and stable display. Reducing f from 60 Hz to 30 Hz would cut the LCD’s dynamic power use by half, but going much lower isn’t feasible due to flicker. Some advanced LCD controllers also offer techniques like alternate-frame blinking of segments (turning them on and off at a very low rate) to save power when absolute real-time visibility isn’t required – though this is only useful for indicators or symbols that can blink as part of normal operation.

In summary, optimizing C, V, and f can shrink an LCD’s power consumption to extremely low levels. In fact, a small segmented LCD module can draw on the order of only microamp-level currents in normal operation. That said, real-world constraints mean none of these parameters can be lowered arbitrarily to zero. Every LCD needs a minimum voltage for legibility and a minimum refresh rate to avoid flicker, and its capacitance is fixed by the required display size and features. Because of these limits, even the most efficient LCD will always consume some continuous power to maintain an image (often a few μA for a modest display). Hardware designers often mitigate this by using ultra-low-power LCD drivers and by updating the display only when necessary. Modern MCUs designed for low-power IoT gadgets usually include built-in LCD controllers that let developers fine-tune the voltage and frame rate, and even operate the LCD in idle modes. By carefully leveraging these low-power design techniques, system builders can ensure the LCD is only drawing the minimum energy needed for acceptable visibility.

Are there display technologies that consume even less power than LCD?

Yes. Bistable displays such as electrophoretic “e-paper” screens (and some cholesteric LCDs) can maintain an image with virtually no power. These technologies only require energy when updating the display content. For example, an e-paper module uses power in short bursts during page updates but zero current to hold a static image. This means that if you update infrequently, the average power consumption can be orders of magnitude lower than a conventional LCD. One source notes that e-ink (electrophoretic) displays can have a typical current on the order of only hundreds of nanoamps per cm² during an update pulse – essentially negligible when averaged over minutes or hours of no change. Such displays are ideal for ultra-low-power devices that only need to show static information or infrequently changing data (for instance, an e-paper price tag or ebook reader). The trade-offs are that these bistable screens tend to refresh slowly (updates can take a second or more) and often require complex drive voltages (e.g. ~15 V pulses for e-paper) plus specialized controllers. They are also typically more expensive than standard LCDs. In summary, for applications where content can remain fixed for long periods, e-paper displays offer even lower power consumption than traditional LCDs, at the cost of speed and sometimes cost/complexity. For most other battery-powered embedded devices that need modestly dynamic readouts, a carefully optimized LCD (with low C, V, and f) provides a good balance of readability and power efficiency.

How can power gating reduce display energy use in embedded systems?

Power gating can significantly reduce a display’s energy use by turning off its most power-hungry parts when they aren’t needed. For example, an embedded system can cut power to the LCD backlight or put the display driver into sleep mode when the screen is idle, eliminating unnecessary energy draw.

In many cases, the display itself can consume over half of an embedded device’s power. Shutting it off during inactivity yields major savings. Fully power gating the display (turning off both the panel and the backlight) stops almost all power use from the screen. Partial gating is also common – for instance, switching off only the LCD backlight while leaving the LCD’s memory or image frozen, or disabling just the display driver electronics. Even just turning off the backlight saves a lot of energy, since the backlight LEDs are often the largest source of display power consumption.

Most modern LCD drivers provide a built-in sleep mode or standby state to drop their power draw. In sleep mode, the driver often halts refreshing the screen and shuts down internal circuits, putting the display in a static (sometimes blank) state. This ultra-low power state drastically cuts consumption, but it comes with limitations. While asleep, the display cannot update content and may appear frozen or dark. Waking it up takes a short amount of time to re-enable the driver and backlight, during which the device cannot instantly show new information. Designers must account for this wake-up delay – if the screen is put to sleep too often, the user might notice lag or unresponsive moments. Thus, low power consumption gains must be balanced with the system’s responsiveness.

Some low power embedded systems use creative techniques to save display energy without completely turning the screen off. One method is segment blinking, where certain LCD segments or icons blink on and off instead of being lit constantly. By only energizing those segments part of the time (for example, flashing an indicator at a low duty cycle), the average power use for that segment drops. Another strategy is partial display shutdown, meaning the system turns off or stops updating unneeded sections of the screen. For example, a device with multiple display regions might disable an unused section to save energy. Reducing the active display area or duty cycle in these ways lowers overall energy use while still presenting essential information to the user.

Circuit diagram showing an NPN transistor used as a power switch for an LCD backlight (LED). The transistor (Q1) connects or disconnects the backlight to save power. In practice, implementing power gating requires hardware control. A transistor can act as a power switch that cuts off the display’s supply when commanded by the microcontroller. Many display modules also provide a driver enable pin or standby input that puts the display into a low-power state when toggled. Using these transistor switches and enable lines, the system can physically disconnect power to the display, achieving true power gating at the circuit level. This ensures no current flows through the display when it’s meant to be off – a common technique in power management in embedded systems to prevent wasted energy.

How does display sleep mode affect usability?

Display sleep mode saves power by turning off the screen when it’s idle, but it can also impact usability. The screen goes blank during sleep and needs a moment to wake up, so the user might experience a slight delay before seeing information again.

In sleep mode, the system cuts power to the backlight and often powers down the display’s driver circuits into a low power mode. This is excellent for conserving energy in low power embedded systems, but it means the display isn’t immediately visible or updating while asleep. When the user reactivates the device (for example, by pressing a button), the display must power back on and re-initialize the LCD driver and backlight. This wake-up process introduces a short delay and can make the device feel less responsive if it happens frequently. A very aggressive sleep setting (where the display turns off after only a brief idle period) might annoy users who find the screen constantly off or slow to update. Designers need to tune the sleep timing and provide quick wake mechanisms to balance power savings with a smooth user experience. In other words, not every power-saving trick is suitable for every scenario – one must consider the user’s need to see data instantly versus the benefit of saving battery power.

Reducing Backlight Power in Embedded LCDs

A backlight’s power use can be minimized by dimming it to only the needed brightness, automatically adjusting it to ambient light, and turning it off when idle. Using efficient drivers instead of resistors and selectively lighting only required screen zones further lowers power consumption in low power embedded systems.

Dim with PWM to Lowest Acceptable Brightness

Using Pulse-Width Modulation (PWM) to dim the backlight reduces energy use by cutting the LED’s on-time. A lower PWM duty cycle means the backlight is off for a larger fraction of each cycle, outputting less light and consuming proportionally less power. For example, PWM dimming can provide fine control from 0% (backlight off) to 100% (full brightness). Running the backlight at the lowest acceptable brightness that still meets visibility needs dramatically curtails its share of the device’s power consumption. In low power embedded systems, this approach extends battery life by avoiding excess illumination.

Ambient Light Sensing for Dynamic Brightness

An ambient light sensor can enable dynamic brightness control that adapts the backlight to surrounding light levels. In a dark environment, the system auto-dims the LCD, and in bright conditions it increases brightness just enough for readability. This adaptive brightness prevents overpowering the backlight when not necessary, directly saving energy. Devices ranging from smartphones to ultra low power Linux gadgets use this technique – by automatically adjusting display brightness, they conserve battery life while maintaining usability.

Inactivity Timer to Turn Off Backlight

Many embedded devices implement an inactivity timer (idle timeout) that turns off the backlight after a period of no user interaction. Cutting the backlight during idle periods prevents wasting power on an unattended screen. For instance, an equipment interface might extinguish its display lighting after, say, 30 seconds of no input. Such a backlight timeout can significantly lengthen standby times. Setting a timer to turn off the backlight when the unit is not in use helps improve battery autonomy and preserve LCD life. The backlight instantly turns on again when the user resumes interaction, ensuring convenience without continuous energy draw.

Use Constant-Current LED Drivers Instead of Resistors

Driving the backlight with a dedicated constant-current LED driver (often a DC-DC converter) avoids the waste of a simple resistor dropper. A series resistor limits LED current but burns off excess voltage as heat, making it an inherently inefficient way to drive an LCD backlight. This method is notably less efficient than using an LED driver circuit and offers no easy way to adjust brightness. In contrast, a proper LED driver delivers regulated current to the backlight with minimal loss. Modern switching LED drivers can exceed 90% efficiency, whereas resistive limiting “is futile…and inefficient”. Using a high-efficiency driver thus reduces energy loss and keeps the backlight current stable despite changes in LED voltage or temperature.

Selective Zone Backlighting (Local Dimming)

Some displays support local dimming, where the backlight is divided into zones that can be dimmed or turned off independently. If available, this selective backlighting technique lets the system illuminate only the portions of the screen that need light. Dark areas of an image get less or no backlight, while bright areas are lit normally. Dimming unused regions not only improves the display’s contrast and apparent black level, but also cuts down on power usage by avoiding full brightness across the entire panel. This kind of dynamic backlighting reduces the load on the LEDs – effectively lowering LED usage and extending their lifetime. In practice, even partial or coarse zoning of the backlight can yield energy savings when large parts of the screen are dark.

How does PWM frequency affect backlight quality?

Lower PWM frequencies can introduce visible flicker in the backlight, while sufficiently high frequencies make the brightness appear steady to the human eye. Typically, a PWM frequency above about 100 Hz is enough to eliminate any perceptible flicker in an LED backlight. For example, a common microcontroller PWM around 490 Hz is well above the flicker fusion threshold and is more than enough to prevent visible pulsing. Increasing the PWM frequency beyond the no-flicker point does not change the perceived brightness or smoothness of the light, but extreme frequencies carry other trade-offs. Very high PWM rates (in the tens of kHz or higher) can lead to slightly higher switching losses and potential electromagnetic interference (EMI) noise. Designers choose a frequency that avoids flicker without incurring unnecessary complexity or energy loss, balancing visual comfort and low power consumption in the backlight control system.

What LCD Technologies and Components Are Best for Low Power Consumption in Embedded Systems?

For low power consumption in embedded systems, opt for simple monochrome segment or character LCDs, which use only ~10-50 μA, or choose memory LCDs and bistable displays for more complex needs, paired with ultra-low-power microcontrollers (MCUs) or drivers designed for efficient LCD control. These choices minimize power use while meeting application needs, making them ideal for low power embedded systems.

Selecting the right hardware is a critical step in low power design. Starting with components optimized for efficiency—rather than trying to optimize a power-hungry display later—sets the stage for effective power management. Monochrome segment LCDs excel in basic applications like digital watches, while memory LCDs and bistable displays suit systems needing occasional updates, such as IoT devices or e-readers.

Low-Power Displays and Components

- Monochrome Segment or Character LCDs

- • Power consumption: ~10-50 μA (no backlight).

- • These displays use few segments, reducing capacitance (C) and keeping dynamic power (P = C·V²·f) low.

- • Perfect for simple displays like numbers or icons in devices running on coin cells or solar power.

- • Memory LCDs

- • Power consumption: ~100-500 μA (only during updates).

- • They retain images with minimal refresh, using power only when pixels change—great for low power IoT devices with status screens.

- • Bistable or E-Paper Displays

- • Power consumption: near zero to hold an image; power used only for updates.

- • Ideal for applications like signage or e-readers where content changes infrequently.

- • Ultra-Low-Power MCUs with LCD Drivers

- • Seek MCUs with “LCD driver” and “ultra-low power” features in their datasheets.

- • These include efficient charge pumps and techniques like charge redistribution, cutting LCD power by up to 40% compared to standard drivers.

- • Integrated drivers reduce losses, a big win for low power microcontroller setups.

- • Avoid High-Power Modules

- • Off-the-shelf modules (e.g., TFT LCDs with touch) often draw unnecessary idle currents.

- • For low power consumption, use a raw LCD panel with a minimal driver to fully control power use.

For comparison, a color TFT LCD with a backlight can draw ~10-100 mA—orders of magnitude more than a segment LCD’s ~10-50 μA. This gap shows why hardware choice matters.

What Are the Trade-Offs When Choosing Low-Power LCD Technologies?

Low-power displays like segment LCDs offer minimal power use but limited functionality, while memory LCDs and bistable displays provide better visuals at the cost of higher power during updates. Matching the display to your application’s needs ensures efficiency without sacrificing usability.

Here’s how to navigate the trade-offs:

- • Segment or Character LCDs: Use for basic data (e.g., numbers, icons) where power must be ultra-low; visuals are basic.

- • Memory LCDs: Pick for occasional updates (e.g., notifications) needing some graphics, balancing power and capability.

- • Bistable Displays: Choose when images must persist without power, accepting slower updates.

- • Color TFTs: Reserve for rich visuals, but expect hundreds of milliamps and complex power needs.

Related Articles:

What Causes Crosstalk in LCDs and Why Do Active Matrix LCDs Perform Better?

What Is the Purpose of Multiplexing in LCDs?

How Does DMA Improve Display Updates in Embedded Systems?

How Do You Integrate a Graphical LCD with an RTOS Task Scheduler?

How Do Page Addressing Mode and Horizontal Addressing Mode Differ in Embedded LCD Systems?

FAQ

Do LCD screens use power if the image is not changing?

Yes. A traditional LCD must keep refreshing and keep its backlight on to maintain an image, so it continues to draw power even for a static picture. Unlike e-paper, an LCD will use nearly the same power for a still image as it does for a changing one.

Will a darker theme or dark mode reduce an LCD’s power consumption?

Not significantly. On an LCD, the backlight is always on at the set brightness, so displaying a mostly black screen doesn’t save much energy. Dark themes mainly benefit OLED displays; for LCDs, dimming the backlight is what actually saves power.

Is OLED more energy-efficient than LCD for battery-powered devices?

Often yes. OLED displays have no backlight and can turn off black pixels completely, which can save power for interfaces with dark or mixed content. However, if an OLED is showing very bright full-screen content continuously, it can draw as much power as an LCD or more.

How can I measure the power consumption of my embedded LCD?

Use a multimeter or power analyzer to measure the current into the display (and its backlight) at various settings. For example, measure the supply current with the backlight at full vs. dim, and with the display on vs. off. This will show how many milliamps the LCD draws in each state and help estimate battery impact.

Does screen size affect an LCD’s power usage?

Yes, larger LCDs generally consume more power. A bigger screen has a larger backlight (using more LEDs or higher current) and more pixels to drive. If you downsize the display or reduce its resolution, there are fewer pixels to refresh and usually a smaller area to illuminate, which lowers the overall power consumption.