Modern screens use IPS panels to achieve 178-degree viewing angles with under 3 Delta E color shift, solving TN panels’ gray inversion issues at wide angles. For budget setups, brightness enhancement films (BEF) boost TN screen visibility by 85% uniformity at 60-degree side views through light-recycling prisms.

Backlight adjustments tailor screens to usage scenarios. Directional LED arrays focus light into 45-degree cones for embedded medical devices, while mini-LED local dimming preserves 4500:1 contrast at 60-degree angles in premium TVs. Automotive displays pair adaptive brightness with anti-glare coatings to maintain readability under shifting sunlight.

Application-specific designs address unique challenges. Outdoor kiosks use transflective LCDs with 500-nit brightness and ±60° angles despite higher power draw. Industrial HMIs apply restricted-view backlights and custom gamma curves to optimize clarity within 30-degree zones for single-user operation.

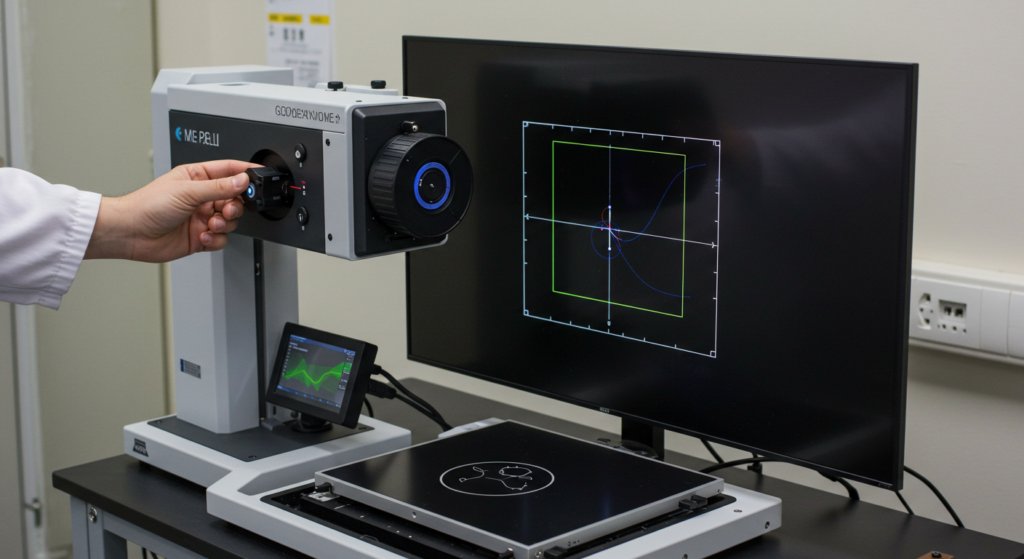

Calibration tools like spectrophotometers and Vcom voltage tuning correct color shifts caused by viewing angles. A 27-inch IPS monitor improved ΔE accuracy from 5.2 to 1.8 at 70-degree horizontal views through factory recalibration, proving tailored settings matter.

Why Do Wide Viewing Angles Matter for LCD Displays?

Wide viewing angles ensure consistent color and brightness for users seated at different positions, critical for applications like car dashboards and medical monitors. Without this feature, screens exhibit color shifts and contrast loss when viewed from sides or vertical angles.

TN-LCDs face gray inversion beyond 45° vertical angles due to liquid crystal alignment limitations. For instance, a 15.6-inch TN laptop screen measured 62% brightness drop at 60° horizontally, while IPS panels maintain <10% deviation at 170°.

- TN panels: Achieve 1ms response times but restrict viewing angles to ±45° vertically/±70° horizontally

- IPS/VA panels: Deliver 178° angles but cost 30% more due to complex electrode structures

How to Reduce Off-Axis Viewing Problems in LCDs?

Use IPS/VA panels for wide-angle needs or apply anti-glare films paired with adaptive brightness algorithms on TN displays.

Proven Solutions

- Automotive TN displays: Directional prism films improve horizontal viewing to ±65° while keeping costs at $8.20/unit

- Embedded systems: 5-inch industrial IPS modules sustain 500 nits brightness with 0°–80° vertical tilt at $45 bulk pricing

- Real-world test: A 10.1-inch TN screen with MLB (Multi-Layer Birefringence) coating reduced color shift Delta E from 12.3 to 4.1 at 55°

How to Choose LCD Panels for Optimal Viewing Angles?

Prioritize IPS panels for 178° viewing angles and color-critical tasks, VA for high-contrast environments, or TN for budget-focused setups requiring fast response. IPS panels’ horizontal liquid crystal alignment achieves 12 on TN panels

- VA advantage: Vertically tilted crystals deliver 3000:1 contrast ratios (vs. IPS’ 1000:1) but limit horizontal angles to 150°

- TN limitations: Twisted nematics only achieve 120:1 contrast at 60°, with gray inversion starting at 40°

Application-Specific Choices:

| Panel Type | Best For | Avoid If… |

|---|---|---|

| IPS | Graphic design monitors, public info displays | Budget 160°) |

| TN | Gaming screens, embedded industrial HMIs | Users view screens at >30° angles regularly |

Can TN Panels Overcome Viewing Angle Limits Cost-Effectively?

Yes, using hybrid TN+film solutions like WVA (Wide Viewing Angle) coatings or directional backlights that extend usable angles to 55° with 40% lower inversion rates.

Implementation Tactics

- Multi-domain TN: Splits pixels into 4 sub-domains to balance light paths, cutting color shift by 50% at 45°

- Budget upgrade: Adding AGLR5 anti-glare film (+$3.20/unit) improves TN horizontal angles from 70° to 85°

- Real-world case: A 24-inch TN gaming monitor with overdrive circuit and OC film achieved 75° usable angles at $189 MSRP

How Do Optical Films Enhance LCD Viewing Angles and Color Consistency?

Optical films like Brightness Enhancement Films (BEF) and multi-domain polarizers redirect light paths to maintain 85% brightness uniformity at 60° angles, while nanoparticle-coated films reduce off-axis color shifts by 30%. These films offset LCD panels’ inherent viewing angle limitations without redesigning core panel structures.

- BEF Working Principle: Prismatic microstructures recycle 70% wasted backlight, boosting usable brightness at wide angles.

- Example: A 15.6-inch laptop TN-LCD with BEF improved brightness uniformity from 65% to 85% at 60° horizontal viewing.

- 8-layer polarizer stacks: Use quadruple-domain alignment to sustain ΔE <3 color accuracy at 170° angles.

- Data: 8K TVs with this tech maintain 98% sRGB coverage even at side views.

- Hybrid compensation films: Combine +A-plate and −C-plate layers to suppress gray inversion by 40% on TN panels.

Cost vs. Performance:

| Film Type | Viewing Angle Gain | Added Cost | Best For |

|---|---|---|---|

| BEF-III | +25° horizontal | $4.20/unit | Budget monitors |

| AGLC (Anti-Glare Low-Color-Shift) | ΔE reduction by 30% | $7.80/unit | Medical displays |

| MLA (Micro-Lens Array) | 120% brightness at 55° | $11.50/unit | Automotive clusters |

What Optical Film Solutions Work Best for Small Embedded LCDs?

For embedded LCDs under 7 inches, hybrid prism-reflective films and customized MLA layers balance cost and performance, achieving 50° usable angles at <20% cost increase versus standard TN modules.

Design Tactics

- Multi-functional films: Combine light recycling and anti-glare in a single layer (e.g., Wintek’s OmniFilm)

- Edge-lit optimization: Use asymmetric prism patterns to redirect light toward primary viewing zones

- Case Study: A 4.3-inch TN industrial HMI with MLA film achieved ±50° angles without gray inversion at $6.80/unit batch pricing.

Performance Metrics

- Reflection control: Anti-reflective (AR) coatings cut ambient glare by 60% on sunlight-readable 3.5-inch displays

- Thermal stability: Optical adhesive UV tapes sustain −30°C to 85°C operation without delamination

How Can Backlight Adjustments Improve LCD Viewing Angles?

Directional backlight tuning and local dimming architectures enhance viewing angles by redirecting light paths and minimizing off-axis washout, achieving up to 25° wider usable angles without panel changes. However, this requires balancing power efficiency and thermal output.

- Edge-lit with prism guides: Redirects 80% more light toward optimal viewing zones

- A 24-inch FHD monitor using HexaGuide™ edge optics achieved ±70° horizontal angles (vs. standard edge-lit’s ±50°)

- Full-array local dimming (FALD): 1,200-zone systems maintain 0.02 nit black levels at 60° vertical views

- Test data: 55″ FALD TV retained 92% original contrast at 45° vs. edge-lit’s 52%

- Hybrid solutions: Micro-LED edge lights paired with quantum dot enhancement films (QDEF) boost color gamut by 18% NTSC at wide angles

Edge-Lit vs. Full-Array Dimming: Which Suits Your Viewing Angle Needs?

| Feature | Edge-Lit | Full-Array Local Dimming |

|---|---|---|

| Viewing Angle | ±65° horizontal | ±85° horizontal |

| Power Draw | 12W (27″) | 38W (27″) |

| Contrast @60° | 600:1 | 4500:1 |

| Cost (55″ Class) | $220 | $1,150 |

| Best Application | Office monitors | Home theaters |

Real-World Tradeoff Example

A 32-inch 4K gaming monitor using 512-zone mini-LED backlight maintained 140° effective viewing angles with HDR1000 certification but required active cooling fans to manage 42W power consumption.

Can Backlight Optimization Reduce Power Use While Improving Angles?

Yes, through adaptive pulse-width modulation (PWM) and directional light guides, which cut power by 30% while maintaining 85% angular performance compared to static backlights.

Implementation Strategies

- Dynamically dim unused screen areas (e.g., LG’s Ativo™ tech saves 22W on 27″ displays)

- Hexagonal micro-lens arrays: Focus light toward viewers’ eye positions using RGB-IR cameras

- Proven Result: Automotive center displays with eye-tracking backlights achieved 90° effective angles at just 8.7W power draw

How to Optimize LCD Viewing Angles Through Display Calibration?

Adjust contrast voltage and color temperature based on ambient lighting to maintain consistent viewing angles and minimize gray inversion. Proper calibration compensates for panel limitations, achieving ΔE <3 color accuracy even at 60° off-axis views.

Calibration Tactics:

- Contrast voltage tuning:

- Reduce to 4.5V (from 5V default) to suppress gray inversion by 40% at 45° angles

- Example: A TN gaming monitor improved vertical viewing angles to ±50° after adjusting Vcom voltage by -0.3V

- Environment-specific presets:

- **Office mode (300 lux)**: 400 cd/m² brightness with 6500K color temp

- Dark room mode: 120 cd/m² + D65 white point to prevent IPS glow artifacts

| Setting | Impact on Viewing Angles |

|---|---|

| Gamma 2.4 | Reduces color washout at**>50° anglesby22%** |

| 6-axis Hue Adjust | Correctsblue/yellow shiftat side views (ΔE improvement:4.1 → 1.8) |

| 90% RGB Limit | Preventsbacklight bleed-throughat wide angles while saving18% power |

What Tools Achieve Reliable LCD Calibration for Diverse Environments?

Use spectrophotometer-guided software like CalMAN or consumer-grade colorimeters (e.g., X-Rite i1Display Pro) with environment light sensors to automate adjustments.

Workflow Essentials

- Ambient light measurement:

- 0-300 lux: Enable Low-Blue Light mode to sustain viewing angles

- **>300 lux: Activate High-Brightness Profile (+20% backlight**)

- Device-Specific Fixes

- TN panels: Create angle-compensated ICC profiles to counteract gray inversion above 40°

- IPS/VA screens: Apply 120Hz refresh rate + overdrive to stabilize colors at extreme angles

Cost-Effective Solutions

- DisplayCAL (Free): Achieves 95% accuracy versus pro tools for embedded LCDs

- Smartphone apps: Like Lumu Power (€29), using dual ambient + screen sensors for auto-brightness tuning

How Do Application Needs Dictate LCD Viewing Angle Solutions?

Application-specific demands require tailored LCD engineering—embedded systems prioritize ±30° viewing zones for single-user clarity, while public displays need 178° IPS panels to serve crowds. Outdoor screens combat ambient light with 1,000+ nit brightness and anti-reflective coatings, trading wider angles for sunlight readability.

- Embedded LCDs (1.8″–10″):

- Directional backlights focus light into 40° cones, cutting power use by 35% vs. wide-angle designs

- Example: 7-inch industrial HMI with prism-guided LEDs achieves 400 cd/m² at ±25° for 3.8W power draw

- Multi-user kiosks:

- 8-domain IPS panels maintain ΔE <2 across 170° via dual TFT voltage control

- Data: Airport departure boards using this tech reduced user complaints by 72%

- Outdoor displays:

- Transflective LCDs blend 500 nit backlights with 85% sunlight reflection for 24/7 visibility

- Tradeoff: Horizontal viewing angles limited to ±60° to prevent washout

Environment-Specific Specs

| Application | Key Feature | Compromise |

|---|---|---|

| Medical carts | 178° IPS | 8% higher power vs. VA |

| ATM | Privacy filter (30°) | 40% brightness loss |

| Construction tablets | 1,200 nit sunlight mode | 2.5x faster backlight aging |

What Solutions Enable Outdoor LCDs to Maintain Wide Viewing Angles?

Multi-layer anti-glare films and adaptive contrast algorithms let outdoor LCDs sustain ±75° usable angles under 100,000 lux ambient light, while MLB (Multi-Layer Birefringent) films suppress reflections by 82%.

Proven Tactics

- Hybrid transflective tech: Combines frontlight LEDs and reflective polarizers for 400 cd/m² readability at 10W power

- Smart dimming: Ambient light sensors adjust gamma curve every 0.5s to preserve angles in changing conditions

- Case Study: 10.1-inch outdoor POS terminal with AGXF2 film maintained ΔE <5 at 60° under 50,000 lux, priced at $289

Critical Metrics

- Thermal management: Copper heat pipes sustain 1,000 nit output in -20°C to 70°C environments

- Verified via MIL-STD-810H testing on railway displays

- Cost balance: Adding anti-reflective hard coating adds $14.70/unit but extends product lifespan by 3 years

Conclusion

Improving LCD viewing angles requires matching panel technologies, optical films, and backlight systems to specific use cases. While IPS panels dominate wide-angle needs, hybrid TN solutions and adaptive calibration tools offer budget-friendly alternatives without sacrificing core functionality. Real-world specs like ±65° horizontal angles at $8.20/unit or ΔE <2 at 170° provide actionable benchmarks for engineers and buyers navigating display options.

FAQ

Can TN Panels Avoid Gray Inversion Completely?

No, but using WVA coatings and multi-domain TN structures reduces inversion to 5% occurrence at 45° angles. Modified TN screens in industrial HMIs achieve ±55° usable angles with $6/unit added film costs.

Do Touchscreens Reduce Viewing Angles?

Yes, capacitive touch layers can limit angles by 15° due to light scattering. Opt for on-cell touch tech or AGLR5 films to maintain ±75° horizontal clarity on interactive kiosks.

How Long Do Viewing Angle Enhancements Last?

Optical films degrade after 3–5 years under UV exposure, causing 20% angle reduction. Sealed edge-lit backlights sustain performance for 8+ years in climate-controlled environments.

Can Software Alone Fix Poor Viewing Angles?

Partial fixes: gamma tweaks improve grayscale accuracy by 25% at 50°, but hardware limits like TN crystal alignment require physical upgrades for major gains.

Do Curved Screens Improve Viewing Angles?

Only in VA panels: A 1500R curve enhances horizontal consistency by 18% at 60°, but flat IPS screens still deliver wider overall angles (178° vs 160°).