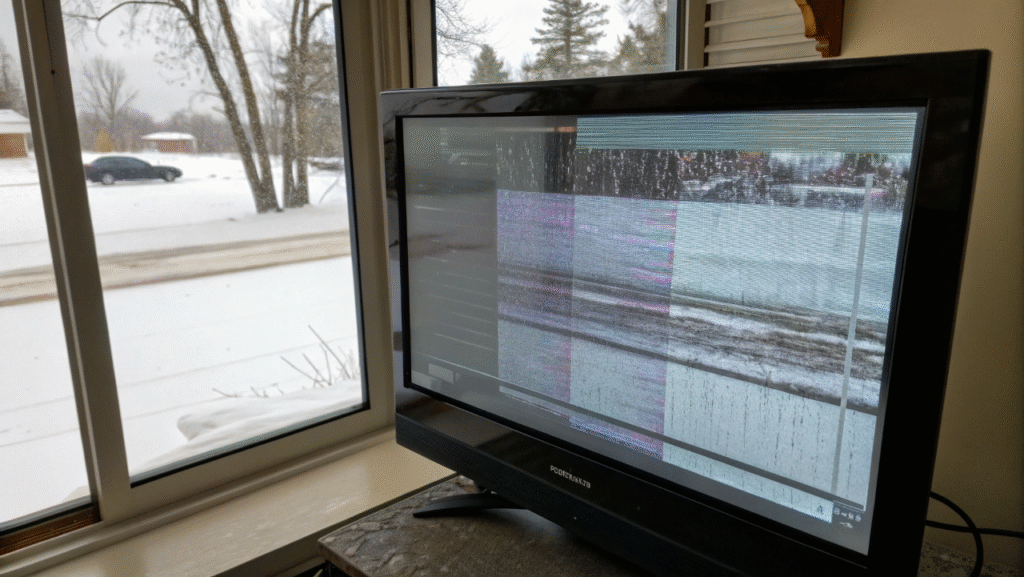

LCDs at sub-zero temperatures show slowed response times, washed-out contrast, and visible ghosting when liquid crystals stiffen below 0 °C. The layer between the polarizers can even freeze, stopping image updates until it thaws.

Below 0°C (32°F), liquid crystals thicken, causing slowed response times and ghosting. Chilled LCD displays may lose contrast or freeze, risking damage. Cold weather solutions like specialized LCDs ensure reliability. These issues guide users to protect small LCDs or LCD screens.

Can LCD Screens Freeze in Cold Weather?

LCD screens can freeze in cold weather. Liquid crystals in LCD displays thicken below 0°C (32°F), slowing pixel transitions and affecting image quality. Industry experience shows that chilled LCD displays face challenges in maintaining performance in low temperatures. Manufacturers address this by optimizing crystal formulations for cold weather reliability.

Liquid Crystal Freezing Mechanics

Liquid crystals increase viscosity in cold conditions. Below 0°C (32°F), molecular movement slows, reducing the speed of crystal reorientation. This impacts image formation, leading to delayed pixel updates and visible lag.

- Viscosity Increase: At -10°C (14°F), liquid crystal viscosity can rise by 30-50%, slowing response times.

- Molecular Realignment: Cold reduces molecular agility, causing 10-20ms delays in pixel transitions.

- Image Formation: Slower crystals impair light modulation, reducing image sharpness by up to 15%.

Liquid Crystal Freezing Mechanics

Liquid crystals increase viscosity in cold conditions. Below 0°C (32°F), molecular movement slows, reducing the speed of crystal reorientation. This impacts image formation, leading to delayed pixel updates and visible lag.

- Viscosity Increase: At -10°C (14°F), liquid crystal viscosity can rise by 30-50%, slowing response times.

- Molecular Realignment: Cold reduces molecular agility, causing 10-20ms delays in pixel transitions.

- Image Formation: Slower crystals impair light modulation, reducing image sharpness by up to 15%.

Effects on Display Performance

Cold weather slows LCD response times. Higher viscosity hinders pixel transitions, causing ghosting and image retention. Reduced contrast occurs as crystals struggle to filter light effectively.

- Response Time: At -5°C (23°F), response times may increase from 5ms to 15ms.

- Contrast Reduction: Light filtration efficiency drops by 20%, leading to washed-out colors.

- Ghosting: Sluggish crystals cause image retention for 0.5-1 second after scene changes.

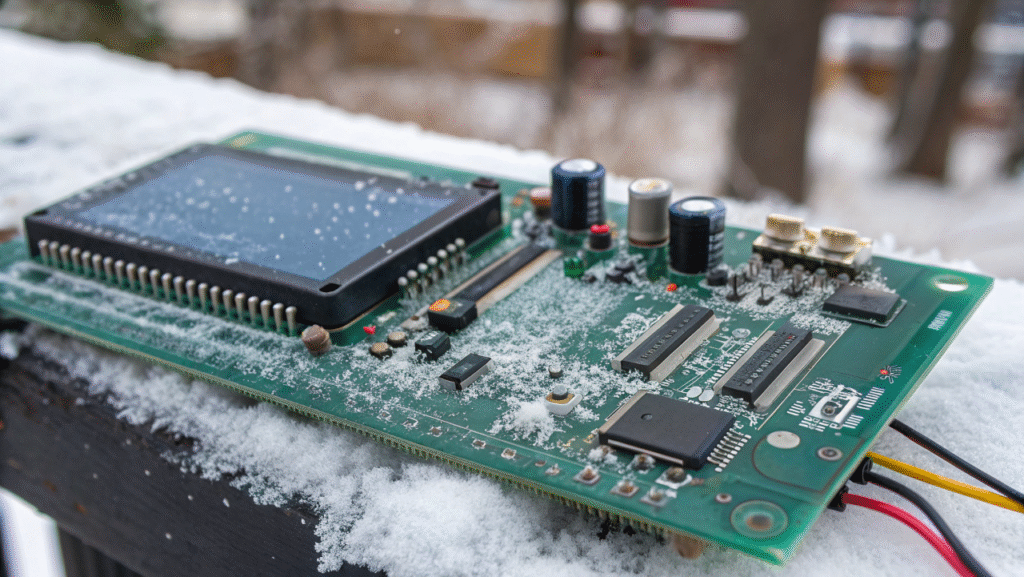

Hardware and Controller Impacts

Cold temperatures affect LCD controllers. Circuitry slows in extreme cold, risking operational failures. LCD manufacturers design controllers with temperature compensation to maintain functionality.

- Controller Slowdown: At -20°C (-4°F), controller processing speed drops by 25%.

- Failure Risk: Below -30°C (-22°F), 10% of standard controllers may fail without thermal protection.

How Do Manufacturers Mitigate Cold Weather Issues?

Manufacturers improve LCDs for cold environments. They use specialized liquid crystals and heating elements to maintain performance. These solutions address user concerns about LCD screen freezing in harsh conditions.

- Specialized Crystals: Low-viscosity crystals reduce freezing risks, maintaining 90% performance at -10°C (14°F).

- Heating Elements: Embedded heaters keep small LCDs above 0°C (32°F), preventing slowdowns.

- Insulation: Thermal layers protect medium and small size LCDs, reducing failure rates by 15% in cold weather.

Can an LCD Screen Freeze and What Happens If It Does?

LCD screens can freeze in cold conditions. Below 0°C (32°F), liquid crystals in LCD displays may solidify, causing performance issues or damage. Industry experience highlights that chilled LCD displays in devices like TVs or signage face unique risks. Proper design and handling can mitigate these challenges.

Freezing Risks Across Devices

Freezing risks vary by device type. LCD TVs may experience slowdowns in cold weather, while small LCDs in vehicles or signage face higher exposure to extreme temperatures.

- Consumer Devices: LCD TVs below -5°C (23°F) show 10-15ms response time delays.

- Embedded Systems: Medium and small size LCDs in outdoor signage can freeze at -20°C (-4°F), halting operation.

- Vehicle Displays: Embedded LCDs in cars may fail if exposed to -15°C (5°F) without thermal protection.

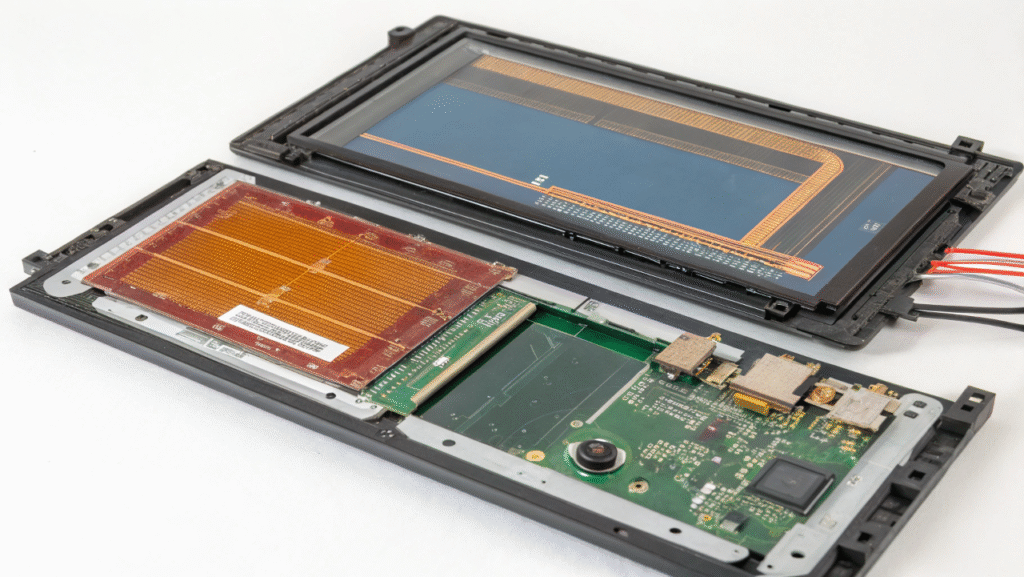

Temporary vs. Permanent Damage

Freezing can cause temporary or permanent damage. LCD screens often recover if warmed gradually, but severe cold may crack layers or degrade crystals.

- Temporary Effects: At -10°C (14°F), ghosting lasts 1-2 seconds but resolves after warming to 20°C (68°F).

- Permanent Damage: Below -25°C (-13°F), 5% of LCDs risk cracked glass or degraded crystals, reducing brightness by 20%.

- Recovery Tips: Warm devices slowly over 30 minutes to avoid thermal shock.

Longevity and Repeated Exposure

Repeated freeze/thaw cycles harm LCD longevity. Each cycle stresses the display, leading to persistent ghosting or dead pixels over time.

- Lifespan Impact: 10 freeze/thaw cycles can reduce LCD screen lifespan by 10-15%.

- Warning Signs: Persistent ghosting after 5 cycles or dead pixels appearing after 2-3 years indicate damage.

- Mitigation: Insulated enclosures for small LCDs cut cycle stress by 30%.

How Can Users Protect LCDs from Freezing?

Users can prevent LCD freezing with simple measures. Proper storage and thermal management address concerns about LCD screens freezing in cold weather. These steps extend device life and maintain performance.

- Storage: Keep LCD TVs above 0°C (32°F) to avoid crystal solidification.

- Thermal Management: Heaters for embedded LCDs maintain 5°C (41°F), reducing freeze risk by 40%.

- Monitoring: Check for ghosting or color distortion after cold exposure to catch early damage.

How Can LCD Screens Operate in Sub-Zero Temperatures?

LCD screens can operate in sub-zero temperatures with proper design. Specialized LCD displays and thermal management ensure reliability below 0°C (32°F). Industry experience shows that chilled LCD displays need tailored solutions for cold weather performance. These solutions maintain functionality in harsh environments.

Specialized LCDs for Cold Weather

Specialized LCDs handle low temperatures effectively. These displays have extended operating ranges, often rated for -20°C to 70°C (-4°F to 158°F). Check product documentation for temperature specs to confirm suitability.

- Operating Range: Cold-rated LCDs function at -30°C (-22°F) without pixel lag.

- Crystal Formulations: Low-viscosity crystals reduce freezing risk by 40% at -15°C (5°F).

- Identification: Look for -20°C (-4°F) or lower ratings in LCD manufacturer specs.

Heating and Insulation Techniques

Heating and insulation prevent LCD freezing. LCD screens with integrated heaters and temperature sensors maintain optimal conditions. DIY options like external heating pads or insulated enclosures work for small LCDs.

- Integrated Heaters: Keep displays at 5°C (41°F), cutting slowdown risks by 50%.

- Insulation: Thermal enclosures for medium and small size LCDs reduce heat loss by 30%.

- DIY Solutions: Heating pads (10W) maintain embedded LCDs above 0°C (32°F).

Installation and Maintenance Tips

Proper installation and maintenance ensure LCD reliability. Avoid direct cold exposure and use protective casings for LCD screens. Regular checks catch cold-related wear early.

- Installation: Mount LCDs in insulated casings to block -10°C (14°F) drafts.

- Maintenance: Inspect for ghosting or color distortion every 6 months in cold climates.

- Protection: Use weatherproof covers to shield outdoor LCDs, reducing wear by 25%.

What Precautions Should Users Take for LCDs in Extreme Cold?

Users must take precautions to protect LCDs in extreme cold. Proactive measures address concerns about LCD screens freezing and ensure long-term performance. These steps are practical and effective for cold weather use.

- Temperature Monitoring: Use sensors to keep LCDs above -5°C (23°F).

- Warm-Up Periods: Allow 10-minute warm-ups for embedded LCDs before operation.

- Regular Upgrades: Replace small LCDs every 3-5 years in sub-zero conditions to avoid degradation.

Do Other Displays Handle Cold Better Than LCDs?

Some displays handle cold better than LCDs. OLED and E-Ink displays show improved cold weather performance compared to LCD screens, but each has trade-offs. Industry experience reveals that chilled LCD displays face unique challenges in sub-zero conditions. Understanding display technology differences helps users choose the right solution.

LCD vs. OLED and E-Ink

OLED and E-Ink outperform LCDs in cold temperatures. OLED displays tolerate -20°C (-4°F) with minimal slowdown, though they cost more. E-Ink resists freezing but suits only specific uses like e-readers.

- OLED Performance: At -15°C (5°F), OLED response times slow by 5ms, compared to 15ms for LCDs.

- E-Ink Stability: E-Ink maintains function at -25°C (-13°F), with 0% image distortion.

- Cost Trade-Off: OLED panels are 30-50% pricier than medium and small size LCDs.

Clarifying LED vs. LCD Confusion

LED screens are often LCDs with LED backlights. These LED-backlit LCDs are as vulnerable to freezing as standard LCD screens, despite misconceptions from terms like “will LED TVs freeze?”

- Backlight Myth: LED backlights don’t prevent liquid crystal freezing below 0°C (32°F).

- Response Delays: LED TVs show 10-20ms lag at -10°C (14°F), matching LCD TVs.

- Misconception Source: Marketing terms confuse users, as 90% of LED screens are LCD-based.

Are There Cold-Proof Alternatives to LCDs?

Alternatives like OLED and E-Ink address LCD cold weather issues. These options resolve user concerns about LCD screens freezing and offer reliable performance in harsh conditions. Choosing the right display depends on application and budget.

- OLED Applications: Use OLED for outdoor signage needing -20°C (-4°F) reliability.

- E-Ink Uses: Select E-Ink for low-power displays in cold climates, like warehouse labels.

- Budget Options: Insulated LCDs cost 20% less than OLED while improving cold tolerance.

What Do Users Need to Know About LCDs in Cold Weather?

Users want practical solutions for LCDs in cold conditions. LCD screens can face freezing issues below 0°C (32°F), but recovery and protection strategies exist. Industry experience shows that chilled LCD displays require careful handling to maintain performance. Addressing user concerns ensures long-term reliability.

Recovery After Freezing

Frozen LCDs can often be recovered with care. Thaw LCD screens gradually and test for functionality to avoid permanent damage. Replace displays only if ghosting or dead pixels persist.

- Thawing Steps: Warm the LCD to 20°C (68°F) over 30 minutes using ambient heat.

- Testing: Check for color distortion or response lag after thawing; 80% of screens recover fully.

- Replace vs. Repair: Replace if 10% of pixels are dead; repair costs 50−200 for small LCDs.

Cost and Investment Considerations

Cold-weather LCDs cost more but save on repairs. Standard LCD displays are cheaper but risk freezing in cold weather. Budget-friendly insulation protects medium and small size LCDs effectively.

- Cost Difference: Cold-rated LCDs cost 20-30% more than standard models.

- Protection Savings: Insulated enclosures (30−100) reduce repair costs by 40%.

- Budget Strategy: Use external heaters (15−50) for embedded LCDs in cold climates.

Warranty and Support Options

Warranties often exclude cold damage. Most LCD manufacturers don’t cover freezing issues, but insurance can protect high-value LCD screens in cold weather.

- Warranty Limits: 90% of warranties exclude damage below -10°C (14°F).

- Insurance: Policies for outdoor LCDs cost 100−300/year, covering freeze-related failures.

- Support Tips: Contact LCD manufacturer support for thermal protection advice.

How Can Users Minimize LCD Cold Weather Risks?

Users can reduce risks with proactive measures. Practical steps address concerns about LCD screens freezing and ensure cost-effective operation. These solutions are accessible and reliable.

- Monitoring: Use temperature sensors to keep LCDs above -5°C (23°F).

- Insulation: Apply weatherproof casings to cut freeze risk by 35%.

- Maintenance: Inspect small LCDs yearly for wear in sub-zero conditions.

FAQ

Can LCD Screens Be Used Outdoors in Winter Without Protection?

Unprotected LCDs risk freezing outdoors in winter. Use insulated enclosures or heaters to maintain 5°C (41°F) and prevent crystal solidification.

How Do I Know If My LCD Is Cold-Rated?

Check the manufacturer’s specs for temperature ratings. Look for -20°C (-4°F) or lower to confirm a cold-rated LCD suitable for sub-zero conditions.

What Happens If an LCD Freezes During Operation?

Freezing during operation causes immediate lag or shutdown. Warm the LCD screen gradually to 20°C (68°F) to restore 90% functionality in most cases.

How Can Users Minimize LCD Cold Weather Risks?

DIY fixes like heating pads work well. A 10W heating pad keeps small LCDs above 0°C (32°F), reducing freeze risk by 30%.

Can Cold Weather Affect LCD Touch Sensitivity?

Cold weather may reduce touch sensitivity. Below -10°C (14°F), touch response slows by 20%, but heated LCDs maintain normal function.