A timing controller, or TCON, makes sure each pixel in an LCD gets the right signal at the right time. The TCON takes digital image data from the main board and sends out timing signals like HSYNC, VSYNC, and pixel clock. These signals tell every part of the LCD panel when to update, so images look smooth and sharp. The TCON also splits and organizes data for each row and column, preventing flicker and screen tearing. By understanding what the TCON does, you can find out why LCD panels need precise timing to show stable pictures. The following sections will break down how TCONs work, what goes wrong when they fail, and how they connect with other LCD parts.

What does the TCON board do in an LCD display?

The TCON board serves as the main controller that receives image data from the main board, processes timing signals and pixel data, and sends this information directly to the LCD panel(What is an LCD controller board?). It manages synchronization signals—like HSYNC (Horizontal Sync) and VSYNC (Vertical Sync)—to keep every pixel updating at the correct time. It also takes care of the conversion of digital signals into analog signals so the panel can display clear images. The TCON board ensures that the picture looks sharp, smooth, and free from flicker.

In many LCD display projects, a dedicated TCON board is used between the main control board and the LCD module. For example, when building a system with a large, embedded LCD, the main board sends raw image data and commands to the TCON. The TCON then adjusts the timing, handles overdrive functions to reduce blur, and ensures all LCD panel rows and columns receive the right signals. Direct management of HSYNC and VSYNC signals avoids issues like ghosting or screen tearing. Engineers often check if the TCON board is handling pixel data and sync signals properly when troubleshooting image quality.

What are the main timing signals handled by the TCON board?

The TCON board handles signals like HSYNC and VSYNC. These signals keep all pixels updating on time, so images move smoothly on the display. The HSYNC signal updates each horizontal line of pixels, and VSYNC refreshes the entire image. If these signals don’t match the display’s needs, the screen may flicker or show lines.

Most LCD systems require engineers to measure HSYNC and VSYNC output from the TCON using an oscilloscope. The right timing controller output gives a stable, clear image. If there is jitter or mismatch in these signals, issues like screen tearing or incomplete image refresh can appear. Technicians usually start with these checks when solving display quality problems in LCD modules.

TCON Timing Signal Overview

| Signal | Purpose | Impact if Wrong |

|---|---|---|

| HSYNC | Refreshes horizontal lines | Horizontal lines break or flicker |

| VSYNC | Refreshes full image frame | Image flickers or rolls |

How does the TCON convert digital signals for the LCD?

The TCON board takes digital image data from the main board and generates the correct analog voltages for the LCD panel’s pixels. Built-in circuits translate binary pixel codes into voltage steps for each subpixel. Without this, the LCD can’t show images, because the panel only responds to changing voltages.

In high-quality projects, the way the TCON converts digital to analog is key to sharpness and color clarity. Problems like incorrect colors, dim screens, or strange patterns often point to issues in the TCON’s output stage. Careful tuning and matching of signals are important for high-resolution embedded LCD modules.

Digital to Analog Conversion Process (Numbered Steps)

- 1. Main board sends digital image data and sync signals to the TCON board

- 2. TCON organizes and processes pixel data

- 3. TCON creates matching HSYNC/VSYNC signals for the display

- 4. TCON outputs analog voltages to LCD module rows and columns

- 5. LCD panel pixels light up to form the correct image

How Do Synchronization Signals Ensure Smooth LCD Display Performance?

| ignal | Function | Impact on Display |

|---|---|---|

| HSYNC | Starts a new display line. | Ensures pixels align in rows correctly. |

| VSYNC | Begins a new display frame. | Prevents screen tearing during refresh. |

| Pixel Clock | Times each pixel’s data. | Controls speed of image rendering. |

What Does HSYNC Do in Display Synchronization?

HSYNC (Horizontal Sync) signals the start of a new display line in an LCD. It tells the TCON when to move to the next row of pixels, ensuring accurate image rendering across the screen.

In a display calibration project, technicians noticed that a faulty HSYNC signal caused horizontal misalignment, making images appear skewed. The TCON uses HSYNC to organize pixel data row by row. Without it, pixels would not align properly, leading to distorted visuals.

The following list explains HSYNC functionality:

- • Triggers new line: Initiates the next row of pixel data.

- • Coordinates timing: Aligns pixels with the Pixel Clock.

- • Prevents misalignment: Ensures rows display correctly.

What Is the Role of VSYNC in Displays?

VSYNC (Vertical Sync) signals the start of a new display frame, allowing the LCD to refresh the entire screen. It ensures the display updates in sync with the source, avoiding screen tearing.

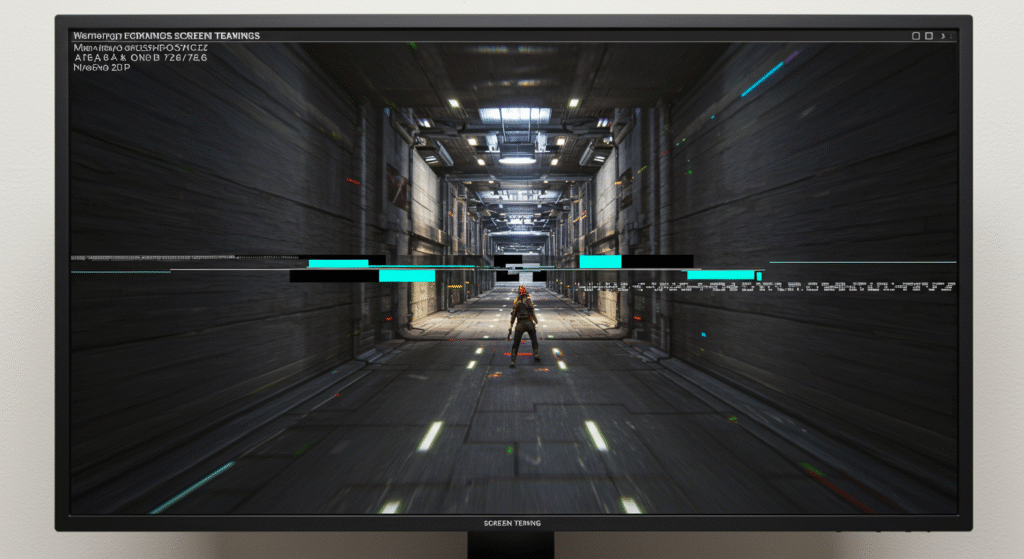

In a video playback test, engineers observed screen tearing when VSYNC failed, causing parts of the screen to show mismatched frames. VSYNC synchronizes the frame refresh with the source’s output, ensuring smooth transitions between frames.

The list below highlights VSYNC’s key tasks:

- • Starts new frame: Begins a full-screen refresh.

- • Syncs with source: Matches display timing to input data.

- • Avoids tearing: Prevents visual artifacts during motion.

How Does the Pixel Clock Affect Display Performance?

| Step | Description |

|---|---|

| Data Timing | Sets pace for pixel data delivery. |

| Pixel Activation | Ensures pixels light up in sequence. |

| Display Stability | Prevents flickering or artifacts. |

How Does a TCON Distribute Processed Signals for Image Formation?

The timing controller (TCON) sends processed signals to gate drivers and source drivers to control liquid crystal cells in an LCD display. This process ensures pixels light up correctly to form clear images.

The TCON processes digital image data and distributes it to the drivers. In a project repairing a monitor, technicians found that a faulty TCON caused blank screens because signals did not reach the gate drivers. The gate drivers activate rows of liquid crystal cells, while source drivers adjust voltage levels to control pixel color and brightness. This collaboration produces accurate visuals.

What Do Gate Drivers Do in LCD Displays?

Gate drivers activate rows of liquid crystal cells in an LCD display. They receive processed signals from the TCON to turn on specific rows for pixel activation.

In a display manufacturing project, engineers observed that defective gate drivers caused horizontal lines across the screen due to improper row activation. The gate drivers open rows sequentially, allowing source drivers to send pixel data. This ensures the correct rows light up at the right time.

The following list explains gate driver functions:

- • Activates rows: Turns on liquid crystal cells row by row.

- • Receives TCON signals: Processes row signals for timing.

- • Enables pixel control: Allows source drivers to set pixel data.

How Do Source Drivers Control Pixel Appearance?

| Step | Description |

|---|---|

| Receives Data | Gets pixel data from the TCON. |

| Adjusts Voltage | Sets voltage levels for pixels. |

| Controls Pixels | Twists liquid crystals for color display. |

What Are the Differences Between Embedded and External TCONs in Display Systems?

| Feature | Embedded TCON | External TCON Board |

|---|---|---|

| Location | Inside the display module | Separate from the display panel |

| Size Impact | Compact, saves space | Requires additional space |

| Flexibility | Fixed, harder to upgrade | Easy to replace or modify |

| Use Case | Small display types like laptops | Large or modular display systems |

How Are Embedded TCONs Integrated into Display Modules?

Embedded TCONs are built directly into the display module, connecting to gate drivers and source drivers to control image data. This design reduces size and streamlines manufacturing.

In a tablet display project, engineers integrated an embedded TCON to minimize the device’s thickness. The TCON was part of the LCD module, directly linked to the panel’s drivers. This setup ensured efficient signal processing but limited repair options. Embedded TCONs suit compact devices where space is critical.

The following list explains embedded TCON integration:

- • Built-in design: Part of the display module circuitry.

- • Driver connection: Links to gate drivers and source drivers.

- • Compact application: Used in small display types like phones.

How Do External TCON Boards Function in Display Systems?

External TCON boards operate as separate components, connecting to the display module via cables or connectors. They process image data and send it to gate drivers and source drivers for display.

In a monitor repair project, technicians swapped an external TCON board to resolve flickering images, avoiding panel replacement. The external design allows easier upgrades and repairs but requires more space. External TCON boards are common in larger display systems like TVs.

The list below outlines external TCON board functions:

- • Standalone operation: Processes image data independently.

- • Flexible connection: Links to the display module via connectors.

- • Repair ease: Simplifies TCON replacement in large systems.

How Does LCD Overdrive Enhance Display Performance with TCON?

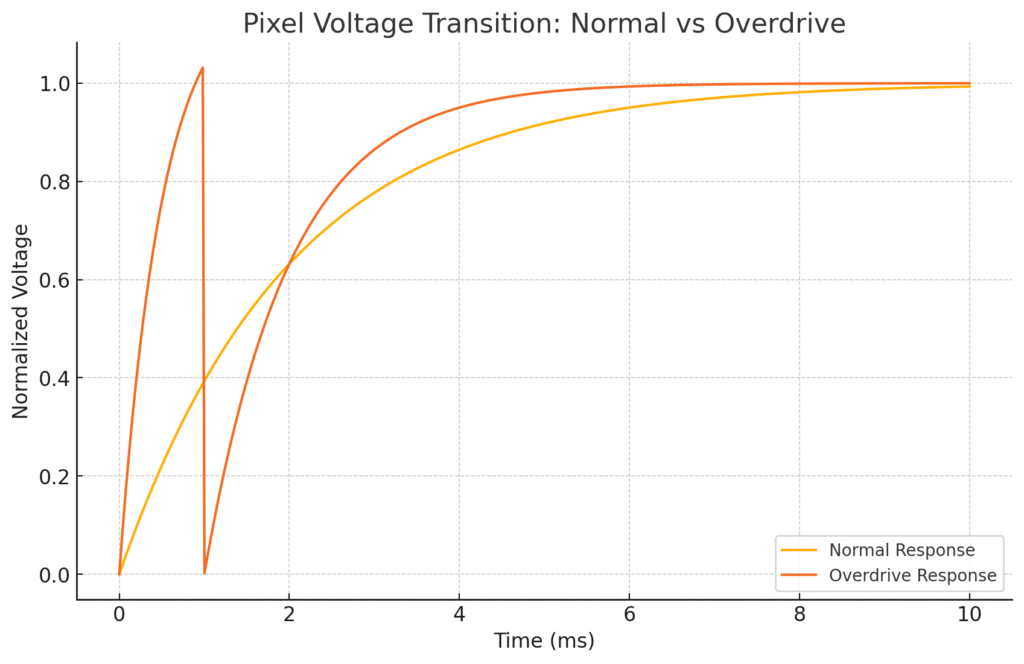

LCD overdrive speeds up pixel response times in displays by applying higher voltage levels to liquid crystal cells, reducing motion blur. The timing controller (TCON) manages this process to ensure smooth and clear visuals.

LCD overdrive works by temporarily increasing voltage to make pixels change states faster. In a gaming monitor project, engineers used overdrive to reduce motion blur during fast-paced scenes. The TCON adjusts overdrive settings based on image data, ensuring pixel transitions occur quickly without overshooting, which could cause visual artifacts.

What Is LCD Overdrive Technology?

LCD overdrive is a technique that accelerates pixel response times by applying higher voltage levels to liquid crystal cells. This reduces the time pixels take to change colors, improving display clarity.

In a high-refresh-rate display project, engineers implemented overdrive to ensure crisp visuals during rapid image changes. Without overdrive, slow pixel transitions cause motion blur, especially in dynamic content like videos or games. The TCON calculates the necessary voltage boost for each pixel.

The following list explains LCD overdrive functions:

- • Speeds up pixels: Increases voltage for faster pixel transitions.

- • Reduces blur: Minimizes motion blur in fast-moving images.

- • TCON control: Adjusts overdrive settings for optimal performance.

How Does the TCON Reduce Motion Blur Using Overdrive?

| Step | Description |

|---|---|

| Analyze Data | TCON processes image data for transitions. |

| Adjust Voltage | Applies overdrive voltage to pixels. |

| Reduce Blur | Ensures fast pixel response for clarity. |

Related Articles:

What is the difference between using an LCD in 4-bit mode versus 8-bit mode when interfacing?

How is CAN or LIN Bus Integration Handled with LCD Modules?

How Does DMA Improve Display Updates in Embedded Systems?

What Is Color Inversion in LCD Displays?

What Causes Crosstalk in LCDs and Why Do Active Matrix LCDs Perform Better?

FAQ

Can a Faulty TCON Cause Permanent Damage to an LCD Display?

A faulty TCON typically does not damage the LCD panel itself. It disrupts signal processing, causing issues like no display or distorted images, which can often be fixed by replacing the TCON.

How Can I Test if My TCON Is Malfunctioning?

Check for flickering screens, vertical lines, or no display, then test by swapping the TCON or inspecting its connections. A technician can use diagnostic tools to confirm TCON issues.

Are TCONs Compatible Across Different Display Models?

TCONs are often model-specific due to unique display module requirements. Always verify compatibility with the display’s gate drivers and source drivers before replacement.

What Happens if LCD Overdrive Is Set Too High?

Excessive LCD overdrive can cause visual artifacts like inverse ghosting. The TCON must balance voltage levels to avoid overshooting during pixel transitions.