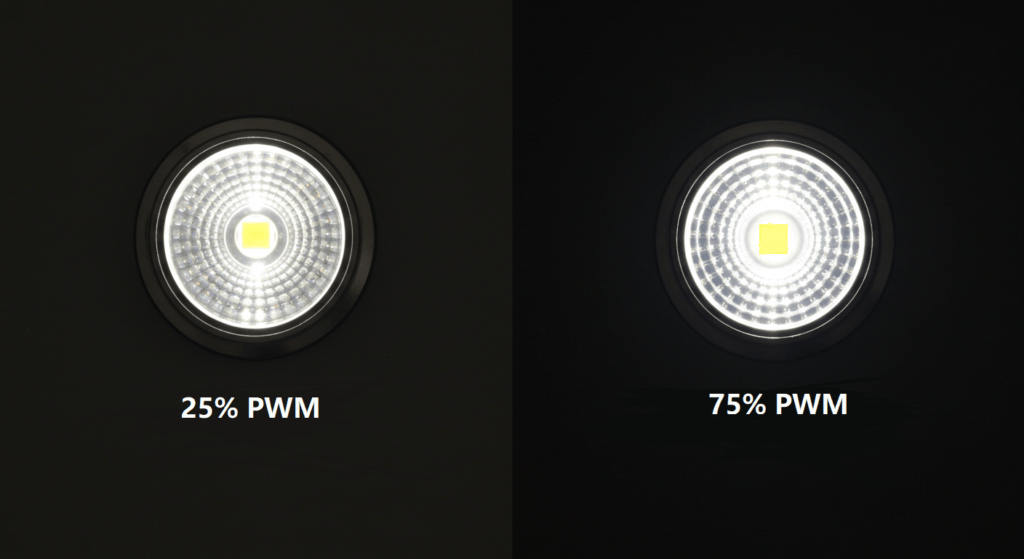

PWM switches LEDs on and off fast with a pwm frequency, using the pwm duty cycle to set brightness levels. A 75% duty cycle keeps lights on longer, making screens bright, while 25% dims them down.

This saves power compared to old methods, a big deal for pwm displays in phones and laptops. Users see steady light because eyes can’t catch the quick pulse width modulation flickers.

Flicker worries some people, though, especially at low hertz pwm like 100 Hz. That’s why designers tweak pwm led controllers to hit higher frequencies, like 1,000 Hz.

The trick lies in balancing efficiency with comfort in screen pwm setups. This article digs into how PWM works, its perks, and fixes for those flicker headaches.

From motors to car lights, PWM stretches beyond screens, showing its real muscle. Each section ahead unpacks these angles to help users and tech fans get it.

How Does Pulse Width Modulation Work in Practice?

Pulse width modulation (PWM) works by creating a pulse width modulated signal that switches between high and low voltages at a set pwm frequency, adjusting the pwm pulse width to control power. The pwm duty cycle determines the average output, like dimming an LED or driving a motor.

This method stands out because it efficiently manages power without wasting energy as heat, unlike older analog systems. Engineers tweak the pulse width modulation frequency and duty cycle to fit specific needs, making it a go-to for precise control in modern devices.

- A pulse width modulator generates a square wave, say at 5V, toggling on and off.

- For a 25% duty cycle, the signal stays high for 1/4 of the period, averaging 1.25V output.

- Devices like pwm led drivers use this to adjust brightness in pwm led lights by changing the pulse width modulation duty cycle.

- Microcontrollers, such as those with Arduino pulse width features, rely on built-in timers to produce the pwm output accurately.

What Affects PWM Performance?

PWM performance hinges on the pwm frequency and hardware setup, impacting flicker and efficiency.

Users might not notice flicker at 100–400 Hz, but cameras or sensitive eyes could. Higher frequencies, like 1,000 Hz or more, fix this and cut noise in systems like pwm led controllers.

- Low hertz pwm (e.g., 100 Hz) suits basic tasks but may show pwm flicker on video.

- Fast-switching FET transistors in a pwm module led keep the signal clean and responsive.

- The pulse width modulation control adjusts dynamically, ensuring stable output even under load changes.

How Does PWM Adjust Backlight Brightness in Displays?

PWM adjusts backlight brightness by pulsing LEDs on and off at a set pwm frequency, using the pwm duty cycle to control intensity—75% duty cycle for bright, 25% for dim. The human eye blends these pulses into steady light thanks to persistence (pulse width modulation dimmer).

This technique beats analog dimming because it saves power and gives precise control over led intensity. Designers pick the right pulse width modulation frequency to keep screens comfortable and efficient, a trick that shapes modern display tech.

- At 75% duty cycle, LEDs in a pwm led setup stay on longer per cycle, pushing brightness up.

- A 25% duty cycle cuts on-time, dimming the pwm led lights without voltage tweaks.

- Standard 100–400 Hz suits most pwm screens, keeping flicker below notice for users.

- High-end pwm led controllers hit 1,000 Hz or more, ensuring smooth visuals even under fast motion.

Why Does PWM Frequency Matter in Displays?

PWM frequency matters because it affects flicker visibility and eye comfort in pulse width modulation monitors.

Low hertz pwm like 100 Hz works for basic LCDs but might bug sensitive viewers. Jump to 1,920 Hz, as in some smartphones, and flicker vanishes, making pwm displays feel effortless to use.

- A pwm screen at 400 Hz balances power use and flicker-free viewing for most people.

- Devices like the Xiaomi 13 push >1,920 Hz in their pulse width modulation control, cutting eye strain.

- Certified flicker-free pwm monitors lean on high pwm frequency to stay easy on the eyes during long sessions.

What Makes PWM Better Than Other Dimming Methods?

PWM beats other methods by delivering power efficiently with a adjustable pwm duty cycle, cutting energy use, and keeping led intensity precise. It also holds color stability steady across brightness levels, unlike DC dimming.

This approach shines in devices needing long battery life, like pwm led lights, because it avoids wasteful heat from resistors. Its ability to fine-tune output with pulse width modulation control gives engineers an edge in performance and user experience.

- With PWM, a 5x current pulse for 1/5 of the time slashes power use by 50%, far better than DC’s constant drain.

- The duty cycle vs frequency setup allows smooth control from 0% to 100%, outpacing DC’s narrower range.

- A pwm led driver adjusts brightness without shifting hues, keeping led pulse output consistent.

- Battery-powered gadgets lean on pwm explained logic to stretch runtime without sacrificing function.

How Does PWM Ensure Color Accuracy?

PWM ensures color accuracy by pulsing LEDs at fixed pwm frequency, avoiding the voltage drops that skew colors in DC dimming.

DC methods often dim by lowering voltage, which can tint pwm led output. PWM sidesteps this, letting pulse width modulation dimmer settings maintain true tones even at low brightness.

- At 50% duty cycle, PWM keeps led intensity balanced without altering color profiles.

- High pulse width modulation frequency, like 1,000 Hz, ensures flicker-free stability in pwm led lights.

- Users get consistent visuals across all levels, a perk DC can’t match without extra tweaking.

What Should Designers Consider When Using PWM?

Designers must weigh pwm frequency for user comfort, ensure fine pwm duty cycle control for smooth output, and handle EMI from the pulse width modulated signal. These factors shape how well PWM performs in real-world devices.

Picking the right pulse width modulation frequency avoids flicker while fitting power needs, a balance that defines product quality. Fine-tuning the pwm control also cuts noise and keeps transitions seamless, critical for polished tech like pwm led drivers.

- Frequencies below 100 Hz cause pwm flickering, tiring eyes during long use.

- A 100–400 Hz range suits most pulse width modulation frequency needs, blending efficiency and comfort.

- High-end setups at 1,000 Hz in pwm led controllers cater to sensitive users and HDR displays.

- 16-bit resolution in a pulse width modulation control circuit delivers smooth dimming at low pwm duty cycle levels.

How Can Designers Reduce PWM Noise?

Designers reduce PWM noise by shielding the pulse width modulated signal and optimizing switching speed.

Fast toggling in pwm output creates EMI, which can mess with nearby electronics. Good layout and filters in pwm control setups keep this under control, ensuring clean operation.

- Rapid switching at 1,000 Hz boosts EMI risk but supports crisp led pulse performance.

- Adding shielding around a pwm led driver drops interference to nearby circuits.

- Slower edges on the pulse width modulation output can also quiet noise without hurting efficiency.

What Challenges Do Users Face with PWM, and How Can They Be Fixed?

Users face pwm flicker causing headaches, component wear from pulse width modulation, and hum at low pwm frequency, but high frequencies like 1,000 Hz and smart design fix these. Solutions include boosting pulse width modulation frequency or using hybrid methods like pwm dimming vs dc dimming.

Some people spot pwm flickering with a camera test, and it can strain their eyes, so designers push hertz pwm higher to smooth it out. Adding robust pwm led controllers also cuts wear and noise, making devices more reliable and quiet for users.

- About 10% of users get headaches from 200 Hz pwm flicker, detectable by waving a pencil.

- Frequencies above 1,000 Hz in pwm output stop flicker and suit sensitive eyes.

- LEDs under constant pulse width modulation control last longer with modern pwm led drivers.

- A hum from low-frequency pwm at 200 Hz fades when set past 1 kHz.

How Can PWM Avoid Health Risks?

PWM avoids health risks by using high-frequency pwm above 1,000 Hz to cut pwm flicker.

At 200 Hz, flicker bugs some users, but jumping to pulse width modulation frequency over 1 kHz keeps visuals steady. Hybrid setups blending pwm dimming vs dc dimming also ease strain for those prone to discomfort.

- Testing with a camera shows flicker at 200 Hz on a pwm screen, annoying 10% of people.

- A pwm led controller at 1,500 Hz ensures no headache triggers during long use.

- Mixing DC at low brightness with pulse width modulation explained logic balances comfort and efficiency.

What Else Can PWM Do Beyond Display Backlights?

PWM controls motor speeds with pwm and duty cycle, powers pulse led light in cars, and drives DIY projects using pwm output. It adjusts power delivery across industries by tweaking the pulse width modulation control.

This flexibility makes pwm control a favorite for engineers needing precise output without complex setups. From robotics to car lights, tweaking the pwm duty cycle opens doors to efficient, reliable performance in unexpected places.

- In robotics, a 50% duty cycle via what is pwm control halves motor speed smoothly.

- Car brake lights use pwm industry tricks to keep led pulse bright under varying voltage.

- Arduino’s analogWrite() sends a pwm output to fade pwm led lights or spin motors.

- The pulse width modulation frequency stays fixed while pwm pulse width shifts to match needs.

How Does PWM Fit into DIY Projects?

PWM fits into DIY projects through tools like Arduino pulse width, letting users tweak pwm output for LEDs or motors.

Hobbyists use pwm explained basics to dim lights or adjust speeds with simple code. It’s cheap and easy, turning pulse width modulation control into a go-to for custom builds.

- analogWrite(128) on Arduino sets a 50% duty cycle for steady pwm led fading.

- A motor at 25% pwm duty cycle runs slower, perfect for small pulse led prototypes.

- Low-cost pwm led controllers make tinkering accessible with minimal hardware fuss.

How Will PWM Evolve to Improve User Experience?

PWM will evolve with high-frequency pwm at 1,000 Hz to cut flicker and hybrid led pulse width modulation for better low-light performance. Tools like apps will also tweak screen pwm to boost comfort.

Pushing pwm frequency higher tackles eye strain head-on, a shift that’s already shaping pwm monitors. Pairing it with DC dimming or software fixes gives users more control, blending tech advances with practical relief.

- Screens at 1,000 Hz pwm reduce pwm flicker for sensitive eyes, unlike older 200 Hz setups.

- Hybrid pulse width modulation dimmer mixes PWM at high brightness with DC at low levels for stability.

- Apps like Screen Dimmer use GPU to adjust pwm output, skipping hardware flicker entirely.

- Future pwm led controllers aim for 2,000 Hz to make visuals seamless in bright or dim settings.

What Tools Help Users Avoid PWM Issues?

Tools like apps bypass screen pwm issues by shifting control to the GPU for smoother dimming.

Software like Screen Dimmer tweaks pulse width modulation control without relying on hardware PWM. This helps users dodge flicker or hum, especially on older pwm displays stuck at low frequencies.

- At 200 Hz, a pwm monitor might flicker, but GPU apps override it with steady led intensity.

- Users tweak brightness via pwm explained software, avoiding 100 Hz strain zones.

- Hybrid pwm dimming vs dc dimming in new devices pairs with these tools for a flicker-free fix.

FAQ

Can PWM cause screen tearing in video games?

PWM itself doesn’t cause screen tearing, as that’s tied to refresh rates and GPU sync, not pwm frequency. However, low pulse width modulation frequency like 100 Hz might make flicker more noticeable during fast motion, which users could confuse with tearing.

Does PWM affect battery life in laptops differently than phones?

PWM impacts battery life similarly in both by cutting power use with a lower pwm duty cycle, but laptops often pair it with bigger screens and higher pwm output, draining more power than phones. Phones optimize with smaller pwm led setups for longer runtime.

Is PWM safe for people with epilepsy?

PWM at low hertz pwm like 200 Hz might trigger discomfort in epilepsy-prone users due to pwm flicker, but frequencies above 1,000 Hz reduce this risk. Check device specs or use pulse width modulation dimmer apps to adjust safely.

Why does my LED bulb buzz with PWM dimming?

Buzzing comes from low-frequency pwm (e.g., 100–400 Hz) vibrating components in the pwm led driver, annoying some users. Switching to 1,000 Hz or higher in the pulse width modulation control usually stops the sound.

Can PWM interfere with Wi-Fi or other signals?

PWM can create EMI from its pulse width modulated signal, potentially disrupting Wi-Fi if poorly shielded in devices like pwm led controllers. Good design with filters in pwm control keeps interference low, so check hardware quality.