1. LCD module and LCD screen

LCD modules, such as the 16×2 monochrome COB LCD module, are essentially semi-finished products within the industrial landscape, requiring continuous refinement and development by skilled engineers. These modules serve as the foundational building blocks for a wide range of applications but need significant customization and integration before they can be used in end products. Unlike LCD screens, which are the fully assembled, ready-to-use final products found in devices like computer monitors, LCD modules are sold at a significantly lower price. This cost difference arises because the modules still require substantial development work to meet the specific needs of various applications.

When incorporating LCD modules into products like vape, instudy equipments or multimeters, manufacturers must undertake additional design and engineering efforts to ensure seamless integration. This customization is essential to adapt the generic module into a specialized component that functions correctly within the intended product.

To ensure the successful integration of LCD modules into your products, it’s crucial to source directly from manufacturers who specialize in these components. This direct approach not only provides better pricing but also ensures access to technical support and customization services that can be pivotal during the product development phase. Reliable manufacturers will offer comprehensive support, from initial design consultation to after-sales service, ensuring that the modules meet your exact specifications and performance requirements.

Additionally, engaging with genuine manufacturers allows for greater transparency and control over the quality and reliability of the modules. Manufacturers can provide detailed technical documentation, certification, and quality assurance processes, giving you confidence in the consistency and performance of the components you are incorporating into your products.

In summary, while LCD modules are cost-effective and versatile components, they require careful selection and development to be effectively utilized in final products. Avoid the pitfalls of dealing with intermediaries and seek out direct manufacturers who can offer the expertise, support, and quality assurance needed to bring your products to market successfully.

2. The difference between BOE and Hua Xian Jing

While BOE Display indisputably reigns supreme as the preeminent display manufacturer not just within China but on a global scale, misconceptions often cloud the perception of its operations. Contrary to popular belief, BOE does not oversee the entirety of LCD product manufacturing. Instead, its diverse portfolio spans across various sectors, encompassing Semiconductor Display Business, MLED, Sensor and Solutions Business, IoT Innovation Business, and Smart Medicine and Engineering Business. This expansive reach underscores BOE’s innovative capabilities and its pivotal role in advancing display technology across multiple industries.

BOE’s expertise in producing high-precision LCD screens is well-recognized, positioning it at the forefront of the market for finished display products such as those used in consumer electronics and professional equipment. However, it’s essential to note that BOE’s primary focus is on delivering these fully integrated, high-quality products, rather than the industrial semi-finished screens like LCD Modules. This strategic focus allows BOE to excel in the domains of end-user applications, ensuring top-tier performance and reliability.

On the other hand, the demand for LCD Modules—key components that require further development and integration by engineers—has led to a dynamic market where specialized suppliers like Hua Xian Jing thrive. Hua Xian Jing capitalizes on the exceptional quality of BOE’s components by incorporating them into their own offerings. This approach ensures that customers benefit from the high standards set by BOE while also enjoying the added advantages of Hua Xian Jing’s competitive pricing and extensive support services.

By sourcing a portion of their raw materials from BOE, Hua Xian Jing is able to maintain a high level of quality in their LCD Modules. This collaboration allows them to offer products that meet rigorous standards while remaining cost-effective. In addition, Hua Xian Jing provides professional after-sales service and direct engineer-to-engineer technical support, ensuring that customers receive comprehensive assistance throughout the development process. This level of support is crucial for manufacturers who need to integrate LCD Modules into their products, such as industrial machinery, medical devices, and specialized consumer electronics.

For those in search of LCD Module acquisitions, Hua Xian Jing emerges as the optimal choice, presenting a compelling combination of quality, affordability, and comprehensive support services. Their ability to leverage BOE’s superior components while offering tailored solutions and dedicated technical support makes them a standout player in the industry. This strategic partnership not only enhances the value proposition for Hua Xian Jing’s customers but also solidifies their position as a leading supplier of LCD Modules in a competitive market.

3. How to find a good Chinese source manufacturer?

Navigating the complexities of establishing reliable business relationships with Chinese companies can indeed be challenging, especially for those with no prior experience. The most well-known B2B website, Alibaba, has become inundated with various traders, which has led many companies to lose trust in the platform. In response, some businesses have turned to temporary agents on platforms like Upwork and Fiverr to verify the authenticity of manufacturers. However, this method often proves to be unreliable and insufficient.

Ensuring that the business you are engaging with is trustworthy requires a systematic approach. Here are some essential steps to identify reliable suppliers:

- Verify the Supplier’s Certificates: The first and most crucial step is to check for valid certifications. These documents are essential as they attest to the supplier’s compliance with industry standards and regulations. Certifications such as ISO, CE, and RoHS can provide assurance of quality and reliability. If the supplier lacks the necessary certifications, it is advisable to discontinue further negotiations, as this is a clear indicator of unreliability.

- Engage in Detailed Discussions with Sales Staff: It’s important to have in-depth conversations with the supplier’s sales representatives about the product. This dialogue should cover all aspects of the product, including its specifications, features, and potential after-sales issues. The knowledge and responsiveness of the sales staff are critical indicators of the supplier’s reliability and their ability to address any problems that may arise post-purchase.

- Confirm Delivery Timeframes: Establishing a precise delivery schedule is vital. Unreliable traders often struggle to commit to specific delivery times because they are not the actual manufacturers. If a supplier cannot provide a clear and guaranteed delivery date, this is a red flag that suggests potential future issues. Reliable suppliers will be able to offer a definitive timeline and adhere to it, ensuring a smooth and predictable supply chain.

- Request References and Reviews: Ask the supplier for references from previous clients or look for reviews online. Feedback from other businesses that have worked with the supplier can provide valuable insights into their reliability and quality of service. Verified reviews and testimonials are crucial in building trust and making an informed decision.

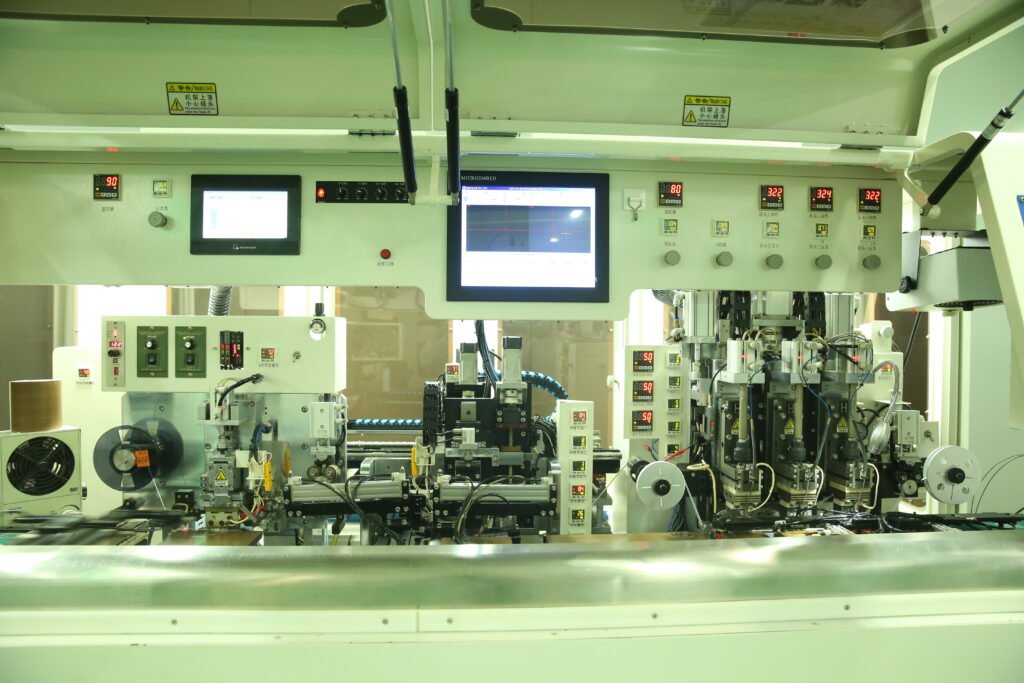

- Conduct Site Visits: If feasible, visit the supplier’s manufacturing facility. This allows you to verify their production capabilities and quality control processes firsthand. A reputable supplier will be transparent and accommodating in arranging such visits. An on-site inspection can reveal a lot about the operational standards and the real scale of the supplier’s business.

- Start with a Small Order: Before committing to a large order, start with a smaller purchase. This allows you to assess the quality of the product and the supplier’s reliability without a significant financial commitment. This step helps to mitigate risks and build confidence in the supplier’s capabilities.

- Utilize Third-Party Inspection Services: Consider employing third-party inspection services that can audit the supplier’s facility and verify their compliance with your standards. These services can provide detailed reports on the supplier’s quality control processes and operational practices.

By following these steps, you can effectively navigate discussions with Chinese suppliers and identify a reliable partner that meets your requirements and provides high-quality products. Additionally, while these steps are crucial, it is highly recommended to visit China and conduct on-site inspections whenever possible. This face-to-face interaction and direct observation are the best ways to ensure the normal operation of your business and establish a solid, trustworthy partnership.