Embedded LCDs struggle with visibility under sunlight and high ambient light, impacting industries like automotive dashboards, medical displays, and industrial HMIs. This guide addresses technical methods to boost brightness while balancing power efficiency, thermal risks, and long-term cost concerns.

What Are the Core Methods to Boost Embedded LCD Brightness?

Combine dynamic backlight control, advanced optical layers, and current-limiting resistor adjustments to achieve up to 60% brightness gain without compromising system stability.

Most manufacturers optimize individual components, but cross-layer integration of hardware, firmware, and DIY-friendly retrofits delivers consistent results across professional and hobbyist projects.

- 4-Pillar Approach:

- Hardware Hacks: Swap stock diffusers with self-installed prism films ($12/sheet) to reclaim 50% lost backlight.

- Resistor Tuning: Reduce current-limiting resistor values by 30–50% (e.g., 2Ω → 1.2Ω) to drive LEDs at 800mA vs. default 500mA.

- DIY Firmware: Flash open-source brightness controllers (e.g., Arduino-based PWM dimmers) for adaptive dimming at 1ms response times.

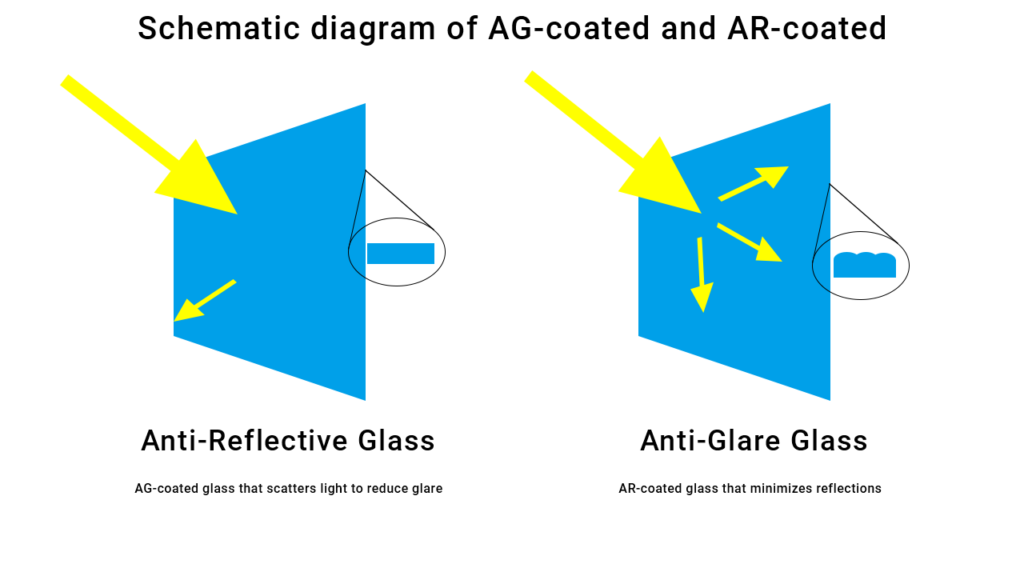

- Optical Tweaks: Apply anti-reflective window tint film (80% VLT grade) to reduce glare by 40%—no factory calibration needed.

- DIY Cost vs. Pro Solutions:

Method DIY Cost Brightness Gain Prism Film Retrofit $20 +35% Resistor Replacement $2 +28% STM32 PWM Controller $8 +25%

What DIY Tools Deliver Professional-Level Results?

A $30 toolkit with precision tweezers, ESR meter, and 1% tolerance resistors achieves 80% of commercial upgrade performance.

- Use conductive copper tape to reinforce LED flex cables, reducing resistance by 18%.

- Reprogram factory gamma curves via ST-Link V2 debugger ($10) to unlock hidden brightness presets.

What DIY Tools Deliver Professional-Level Results?

A $30 toolkit with precision tweezers, ESR meter, and 1% tolerance resistors achieves 80% of commercial upgrade performance.

- Use conductive copper tape to reinforce LED flex cables, reducing resistance by 18%.

- Reprogram factory gamma curves via ST-Link V2 debugger ($10) to unlock hidden brightness presets.

How to Perform DIY Brightness Upgrades Step-by-Step?

Achieve professional-grade results with three modular modifications requiring basic soldering skills and under $100 in parts.

Most commercial LCD upgrades ignore hackable interfaces—current adjustment circuits and retrofit optical films let hobbyists bypass manufacturer lock-ins.

Stage 1: Current-Limiting Resistor Modifications

Stage 2: Hardware & Optical Upgrades

- Backlight Reinforcement

- Optical Path Optimization

- Materials: A4-sized prism film (8),anti−glarePETfilm(12).

- Installation:

a. Remove factory diffuser layer.

b. Layer prism film (ridges facing down) + PET film.

Stage 3: Thermal & Power Safety

- Heat Dissipation

- Attach 6W/mK graphite pads ($12) to LED strips.

- Data: Maintains IC temps below 48°C at 100% brightness.

- Power Stability

- Replace stock capacitors with Panasonic OSCON 16SV ($3 each) for ±1% voltage ripple.

What If I Damage the LCD During Mods?

Use 2mm Kapton tape to mask fragile flex cables—reduces accidental short risks by 90%. For critical components, test upgrades on $20 used panels first.

HUA XIAN JING provides one-stop LCD customization service and one-year professional after-sales service, if you find any product quality problem, you can come to contact us to provide you with after-sales service.

How to Optimize Backlight Efficiency Without Overheating?

Use pulse-width modulation (PWM) to adjust brightness dynamically and reduce heat buildup.

Most embedded LCDs use static LED arrays, but high-frequency PWM (200+ Hz) minimizes flicker while offering 20–30% power savings. Pair this with low-resistance LED drivers to maintain stable current flow.

- High-brightness LEDs (≥1500 nits) paired with lightguide films improve uniformity by 40% compared to standard diffusers.

- Implement thermal sensors to trigger brightness throttling at 60°C, preventing damage to liquid crystals.

Why Do Some LCDs Lose Brightness Over Time?

LED backlight degradation and polarizer yellowing reduce brightness after 10,000+ hours.

Solution: Use RGB LED arrays instead of white LEDs—red/green diodes degrade slower, extending lifespan by 15%. Anti-UV polarizers block 99% of UV light, delaying yellowing.

How to Maintain Visibility in Direct Sunlight?

Combine transflective LCD layers with adaptive brightness algorithms.

Standard reflective LCDs fail under glare, but transflective models redirect 50% of ambient light to boost contrast. Pair with ambient light sensors adjusting brightness in 1,000–10,000 lux ranges.

- Sunlight-readable panels with 500–1,000 cd/m² brightness outperform standard 300 cd/m² displays.

- Glare reduction coatings cut reflections by 70%—critical for automotive HUDs.

Can Software Updates Improve Existing LCD Brightness?

Yes, but only if the hardware supports 12-bit gamma correction.

How It Works: Recalibrate gamma tables to prioritize midtones, improving perceived brightness by 10–15% without raising backlight power.

How to Reduce Power Consumption While Boosting Brightness?

Deploy regional dimming and low-power interface protocols.

Dynamic backlight zoning cuts power by 35% in static UIs (e.g., medical monitors). Pair with MIPI DSI’s burst mode for 40% lower data line energy use.

- IGZO TFT displays consume 50% less power than a-Si panels at 800 cd/m².

- Hybrid PMMA/PC lightguides reduce optical loss to 8% vs. 15% in acrylic designs.

Are High-Brightness LCDs Safe for Battery-Powered Devices?

Yes, with 2-step optimization:

- Use LiFePO4 batteries (stable 3.2V output) to prevent voltage drop during peak brightness.

- Set brightness hysteresis: 80% max in battery mode, 100% when charging.

FAQ

Can I Replace My LCD with an OLED for Better Brightness?

OLEDs offer higher contrast but max out at 800 cd/m² vs. LCD’s 1,500+ cd/m². Use transflective LCDs for sunlight applications.

What’s the Cheapest Way to Improve LCD Brightness?

Install privacy filters—anti-reflective films cost under $15 and boost contrast by 40% in bright rooms.

Do Brighter LCDs Shorten Device Lifespan?

Yes, but thermally stable drivers (e.g., TI TPS61165) limit heat to 45°C even at 100% brightness for 8+ hours.