Struggling to understand what’s inside a capacitive touch screen? This confusion can lead to choosing the wrong technology for your project, causing performance issues and costly rework down the line.

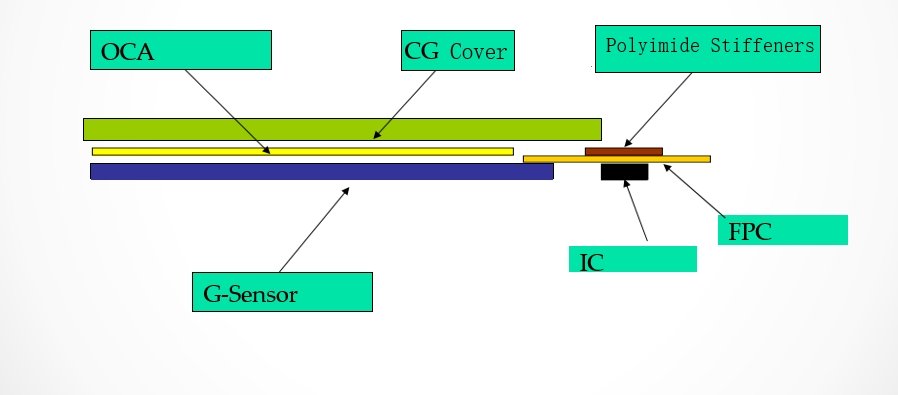

A capacitive touch screen is built from several key layers. These typically include a protective cover lens, an optical adhesive, and a sensor layer with a grid of conductive material. The specific arrangement defines its performance.

In my 13 years in this industry, I’ve seen how these technical details can seem overwhelming. But breaking it down is simpler than you think. Let’s peel back the layers and see how it all comes together.

What Is the Structure of Each Layer in a Capacitive Touch Screen?

Ever wondered how your screen knows exactly where you’re touching it? It’s not magic. It’s a coordinated effort between different layers, each with a specific job to do in detecting your finger’s position.

The cover lens protects the assembly while the sensor layer, made of a transparent conductor, generates an electric field. When your finger

The First Line of Defense

The cover lens is the top surface you physically touch. Its main job is to protect the delicate internal components from scratches, impacts, and the en that. The material—be it glass or plastic—and any surface treatments, like anti-glare or anti-fingerprint coatings, directly affect the user experience and the screen’s durability. It’s the gatekeeper for both your touch and the light coming from the display below.

The Heart of Touch Detection

Beneath the cover lens lies the sensor layer. This is where the real work happens. This layer is typically a piece of glass or film coated with a transparent conductive material, most commonly Indium Tin Oxide (ITO). The ITO is etched into a grid of tiny, invisible wires (X and Y electrodes). This grid creates a stable, uniform electrostatic field. When your conductive finger gets close, it couples with the grid and changes the local capacitance. The screen isn’t feeling pressure; it’s sensing this tiny electrical disturbance(Why Is ITO Glass Vital for LCD Displays and Touchscreens?).

The Brain of the Operation

The change in capacitance is detected by the controller Integrated Circuit (IC), often located on a flexible tail (FPC) connected to the sensor layer. The controller is the brain. It constantly scans the grid of electrodes for any change in capacitance. Once it detects a change, its firmware and algorithms calculate the precise X and Y coordinates of the touch event. It then sends this coordinate data to the device’s main processor, which translates your touch into an action on the screen(What is an LCD controller board?).

Why Are There Different Structures Like G+G, G+F, or G+F+F?

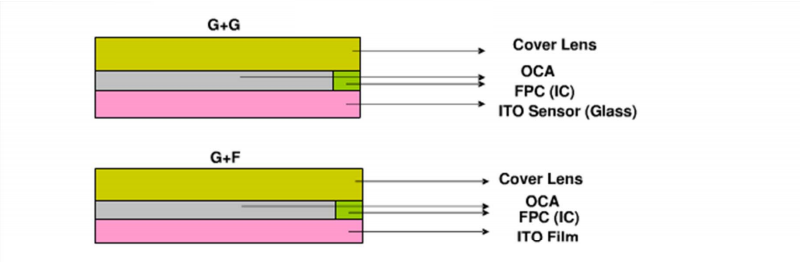

You may have seen acronyms like G+G or G+F when looking at touch screen specifications. These letters aren’t random; they describe the fundamental build of the touch panel and have huge implications for its performance.

These terms describe the materials used for the structure: G stands for Glass and F stands for Film. G+G means a Glass cover lens with a Glass sensor, while G+F means a Glass cover lens with a Film sensor.

This choice impacts everything from durability and thickness to optical clarity and final cost.

Comparing Common Touch Screen Structures

To make it clearer, here is a breakdown of the most common structures I see in the industry.

| Structure | Composition | Pros | Cons | Typical Use Case |

|---|---|---|---|---|

| G+G | Cover Glass + Glass Sensor | Very durable, scratch-resistant, high optical clarity. | Thicker, heavier, more expensive. | Industrial controls, high-end devices, medical equipment. |

| G+F | Cover Glass + Film Sensor | Thinner and lighter than G+G, more cost-effective. | Less durable and optically clear than G+G. | Mid-range smartphones, tablets, consumer electronics. |

| G+F+F | Cover Glass + 2 Film Sensors | Allows for more complex sensor patterns, good for larger screens. | Can be thicker than G+F, potentially lower light transmission. | Laptops, all-in-one PCs. |

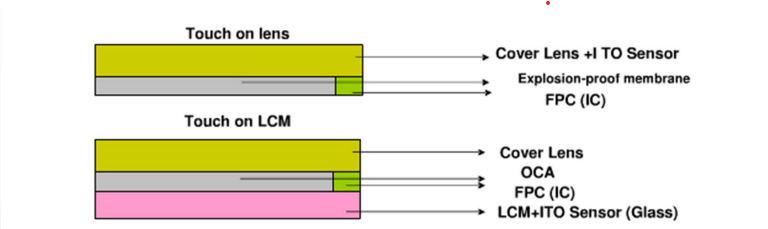

| OGS | One Glass Solution | Thinnest, lightest, best optical clarity. | Less durable, a crack can kill touch function, higher cost. | Premium smartphones, high-end tablets. |

OGS, or One Glass Solution, is a more advanced structure where the ITO sensor layer is patterned directly onto the back of the cover glass. This eliminates an entire layer of substrate and adhesive, leading to the thinnest and most optically pure stack-up. However, it makes the assembly more fragile. If the cover glass breaks, the touch functionality is usually lost completely, making repairs more expensive.

What Are the Typical Failure Modes and How Can They Be Prevented?

In my experience building and troubleshooting LCD modules, I’ve seen a lot of things go wrong. A touch screen is a complex assembly, and failure can occur in several ways. Knowing the weak points is the key to designing a robust product.

The most common failures are physical cracks from impact, sensor damage from flexing or stress, and controller IC malfunctions due to electrical or environmental factors. Prevention focuses on durable materials, smart mechanical design, and proper sealing.

Physical Damage

This is the most obvious failure mode.

- Failure: A cracked or shattered cover lens is the most common issue. Even small scratches can weaken the glass and can sometimes be deep enough to damage the sensor layer underneath.

- Prevention: The first line of defense is material choice. Using chemically strengthened glass like Gorilla Glass greatly increases durability. Another key factor is the design of the product’s housing. A bezel that is raised slightly above the glass surface can protect the edges, which are the most vulnerable points.

Sensor and Connection Failure

This type of failure is less visible but just as critical.

- Failure: The ITO sensor layer is brittle. A sharp impact or excessive flexing of the device can cause microscopic cracks in the conductive traces, leading to dead spots or a completely unresponsive screen. The flexible cable (FPC) that connects the sensor to the mainboard is also a common failure point(What Are the Key Differences Between FFC and FPC?).

- Prevention: Good mechanical design is crucial. The touch panel must be adequately supported within the housing to prevent flexing. For the FPC tail, proper strain relief is essential to avoid damage during assembly or from vibration in the final product.

Environmental Failure

The environment where the device is used plays a huge role in its longevity.

- Failure: Moisture is the enemy. If water gets inside the touch panel, it can cause the layers to delaminate or short-circuit the sensitive electronics. Extreme temperatures can also cause adhesives to fail. Finally, Electrostatic Discharge (ESD) can permanently damage the controller IC(What is Electrostatic Discharge (ESD) and How Can You Prevent It?).

- Prevention: For devices used outdoors or in industrial settings, proper sealing is a must. This is often done with gaskets or adhesives to achieve an IP rating (e.g., IP67). Choosing components and adhesives rated for the expected temperature range is also vital. ESD protection must be designed into the circuit from the start(How is Waterproof Touch Functionality Achieved in LCD Devices?).

What Should Be Considered When Customizing or Integrating a Capacitive Touch Screen?

Taking a standard touch screen off the shelf is one thing, but many projects require a custom solution. When you embark on a custom design, several key factors must be considered from the very beginning to ensure a successful integration(How Does Screen Size Affect Touch Accuracy?).

You must define the operating environment, determine the cover lens specifications (material, shape, printing), select the right controller IC for your feature set, and carefully design the FPC tail and mounting for your specific mechanical enclosure.

Define the Operating Environment

Before any design work begins, you must know where and how the device will be used.

- Will it be used outdoors? If so, it needs to be sunlight readable (requiring optical bonding) and may need UV-resistant materials.

- Will it be exposed to water or dust? This will determine the required IP rating and the need for gaskets and sealing.

- Will the user be wearing gloves? This requires a controller with a higher sensitivity and specific tuning.

Cover Lens Customization

The cover lens is often the most customized part of the assembly.

- Material and Thickness: A rugged industrial device may need a thick 3mm glass lens, while a sleek consumer device might use 0.7mm glass. This choice directly impacts touch sensitivity(How Does Screen Size Affect Touch Accuracy?).

- Shape and Printing: The glass can be cut into custom shapes with holes or notches to fit a unique product design. You can also print logos, button icons, or borders on the rear surface of the glass for a clean, seamless look.

Controller and Firmware Tuning

This is the technical core of the customization process.

- IC Selection: You need to choose a controller that supports the features you need. Do you need 10-point multi-touch? Water rejection (the ability to ignore false touches from water droplets)? Glove support? Stylus support? Different ICs have different capabilities(What Are the Differences Between Single-Touch and Multi-Touch LCD Screens?).

- Firmware Tuning: This cannot be stressed enough. Once the hardware stack-up is defined, the controller’s firmware must be tuned. This involves adjusting dozens of parameters to optimize the SNR, ensuring that the touch screen is sensitive, accurate, and immune to false touches from electrical noise generated by the display or other components. This is a specialized skill and is often the difference between a product that works and one that doesn’t.

Conclusion

Taking a standard touch screen off the shelf is one thing, but many projects require a custom solution. When you embark on a custom design, several key factors must be considered from the very beginning to ensure a successful integration.

You must define the operating environment, determine the cover lens specifications (material, shape, printing), select the right controller IC for your feature set, and carefully design the FPC tail and mounting for your specific mechanical enclosure.

FAQ

How Do Environmental Factors Like Humidity Affect Touch Screen Layers?

High humidity can cause delamination or adhesive failure. Use UV-resistant adhesives and robust materials to ensure durability.

Can Capacitive Touch Screens Work With Gloves or Stylus?

Projected capacitive screens support stylus or special gloves, but surface capacitive screens often don’t. Choose PCAP for versatility.

How Does Screen Size Affect Layer Structure Choices?

Larger screens need stronger materials like G+G for durability. Smaller screens can use G+F for cost savings.

Can capacitive screens be repaired if one layer is damaged?

Usually, it is not cost-effective to repair. It is better to replace the panel with a new one.

Are capacitive touch screens suitable for outdoor environments?

Yes, as long as you use proper sealing, thicker glass, and anti-glare or UV protection, they can work outdoors reliably.