A Zero Insertion Force (ZIF) connector is an electrical connector with a locking mechanism. This mechanism allows you to insert a cable without any force and then secure it for a reliable connection.

How Does the Zero Insertion Force Mechanism Work?

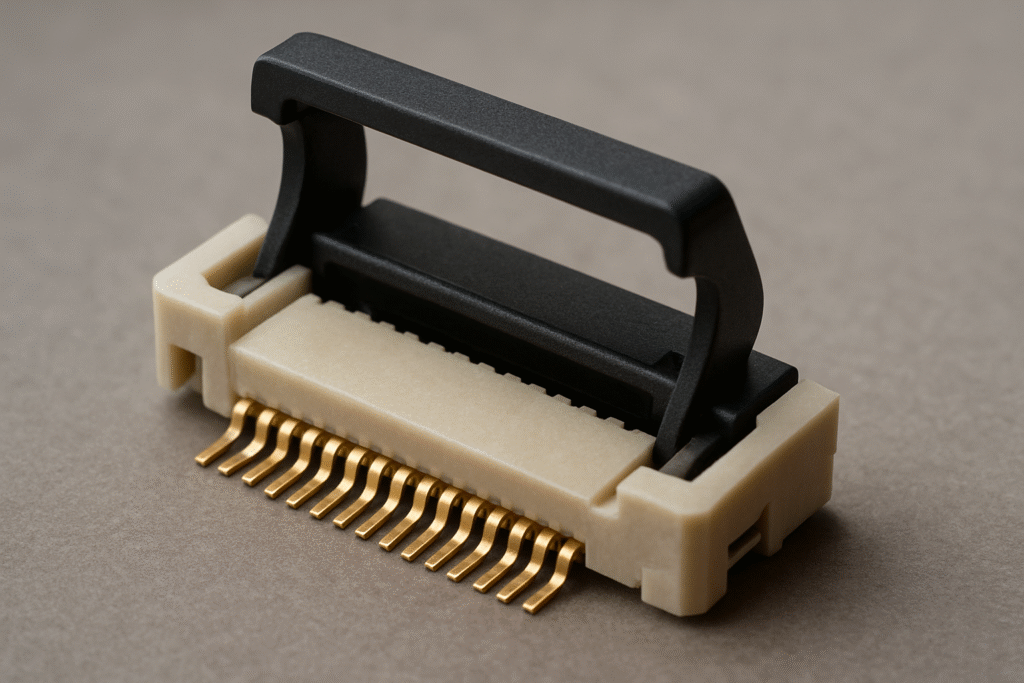

The ZIF mechanism works using a movable actuator. When the actuator is open, there is a gap, allowing a cable to be inserted with zero force. Closing the actuator clamps down on the cable’s contacts.

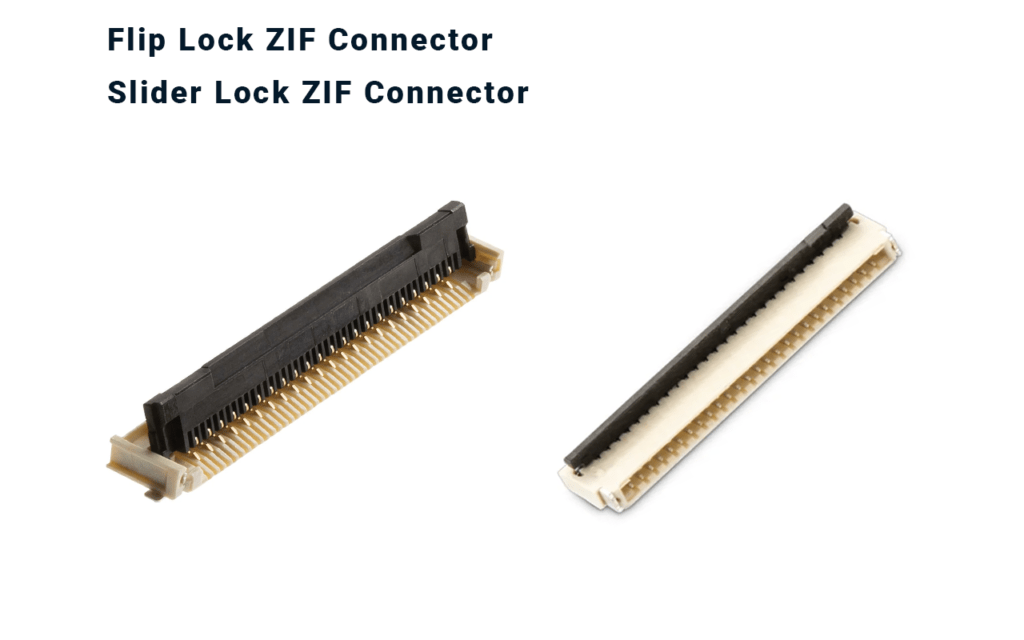

Actuator Types

There are two main styles of actuators you’ll see in the field. Each has its pros and cons depending on the application.

- Flip-Lock (or Hinge) Actuator: This is probably the most common type I see. It’s a small, hinged flap on the connector body. You lift the flap up, which opens the contacts. Slide the cable in, then press the flap down to lock it. This provides a very secure mechanical grip and a satisfying “click” so you know it’s locked. It’s great for applications where the connection needs to be extra reliable.

- Slider Actuator: This type uses a sliding tab. You pull the tab out, insert the cable, and then push the tab back in to secure it. These are often lower profile than flip-lock connectors, which can be useful in very compact devices. However, the locking force might not feel as strong as a flip-lock.

| Feature | Flip-Lock Actuator | Slider Actuator |

|---|---|---|

| Operation | A hinged flap is lifted and closed. | A tab is pulled out and pushed in. |

| Locking Feel | Strong, often with an audible click. | Smoother, less tactile feedback. |

| Profile Height | Generally taller. | Often lower profile. |

| Best For | High vibration, secure connections. | Space-constrained designs. |

What Is Connector Pitch?

Connector pitch is the distance from the center of one contact pin to the center of the next one. It’s a critical measurement that ensures the connector matches the cable perfectly.

Why Pitch Matters

The pitch determines the density of the connection.

- Component Matching: The pitch of the ZIF connector must be identical to the pitch of the Flat Flexible Cable (FFC) or Flexible Printed Circuit (FPC) you are using. A mismatch of even a fraction of a millimeter will make a connection impossible.

- Space and Miniaturization: A smaller pitch allows for more connections in a smaller space. As devices like smartphones and wearables get smaller, the demand for fine-pitch connectors (0.5mm or less) has skyrocketed.

- Electrical Performance: While smaller pitches are great for saving space, they can sometimes introduce challenges like crosstalk between signals, especially in high-speed applications.

Common Pitch Sizes

Here are some of the most common pitch sizes you’ll encounter in the industry and where you might find them.

| Pitch Size | Common Applications | Notes |

|---|---|---|

| 2.54mm | Older electronics, breadboarding, hobbyist projects. | This is the legacy “standard” pitch from dual in-line package (DIP) ICs. |

| 1.25mm | Internal connections in larger devices. | A good balance between size and ease of handling. |

| 1.00mm | LCDs, touch panels, general-purpose connections. | A very common and versatile pitch size. |

| 0.5mm | Smartphones, tablets, cameras, laptops. | This is the dominant pitch for modern consumer electronics. |

| 0.3mm & Below | High-density applications like medical sensors or compact camera modules. | Requires very precise manufacturing and careful handling. |

When I started 13 years ago, 1.0mm and 1.25mm pitches were the norm. Now, almost every new project I work on for a client in Germany or America uses a 0.5mm pitch. It’s a clear trend toward miniaturization.

What Types of Cables Work with ZIF Connectors?

ZIF connectors are primarily designed to be used with Flat Flexible Cables (FFC) and Flexible Printed Circuits (FPC). Both are thin, flat, and have exposed contacts on one side(What Are the Key Differences Between FFC and FPC?).

Flat Flexible Cable (FFC)

- What it is: Think of it as a flat version of a ribbon cable. It consists of multiple flat copper conductors laid parallel to each other and laminated between two layers of plastic insulation, usually polyester.

- How it’s used: The end of the cable has the insulation stripped away to expose the contacts. Sometimes, a stiffener (a small piece of thicker plastic) is added to the end to make it easier to insert into the ZIF connector. FFCs are great for simple, point-to-point connections.

Flexible Printed Circuit (FPC)

- What it is: An FPC is made by etching copper traces onto a flexible polymer base, like polyimide. This allows for more complex circuit patterns, not just straight parallel lines. You can even mount small components like LEDs or resistors directly onto an FPC.

- How it’s used: They connect to ZIF connectors in the same way as FFCs. They are used when the connection is more than just A-to-B, for example, when a single cable needs to route signals to multiple places or incorporate components.

| Feature | Flat Flexible Cable (FFC) | Flexible Printed Circuit (FPC) |

|---|---|---|

| Structure | Straight, parallel copper conductors. | Complex, etched copper traces. |

| Complexity | Simple point-to-point connections. | Can have complex circuits and components. |

| Cost | Generally less expensive. | More expensive due to manufacturing process. |

| Flexibility | Very flexible and can be folded. | Flexible, but component areas are rigid. |

For many of the custom LCD modules we produce, the choice depends on the client’s needs. If it’s a simple display connection, an FFC is cost-effective. If the client needs to integrate backlight controls or a touch sensor into the same tail, an FPC is the way to go.

Where Are ZIF Connectors Most Commonly Used?

ZIF connectors are most commonly used in compact electronic devices where space is limited and a reliable, reworkable connection between a mainboard and a peripheral is needed.

Consumer Electronics

- Laptops: They connect the keyboard and trackpad to the motherboard. They also connect the main display panel.

- Smartphones & Tablets: Used for connecting cameras, screens, batteries, and button assemblies. The push for thinner phones is a major driver of ZIF innovation.

- Digital Cameras: Connecting the lens assembly, sensor, and LCD screen.

Automotive Industry

- Infotainment Systems: Connecting the main display and touch panel.

- Instrument Clusters: Connecting the digital dashboard screens.

- Sensor Modules: For things like cameras and LIDAR.

Industrial and Medical Equipment

Reliability is critical in these fields.

- Industrial Control Panels: Connecting displays and keypads on factory machinery.

- Medical Devices: In everything from portable ultrasound machines to patient monitors. The ability to easily replace a module (like a screen) in the field is a huge benefit.

What Are the Latest Developments in ZIF Connector Technology?

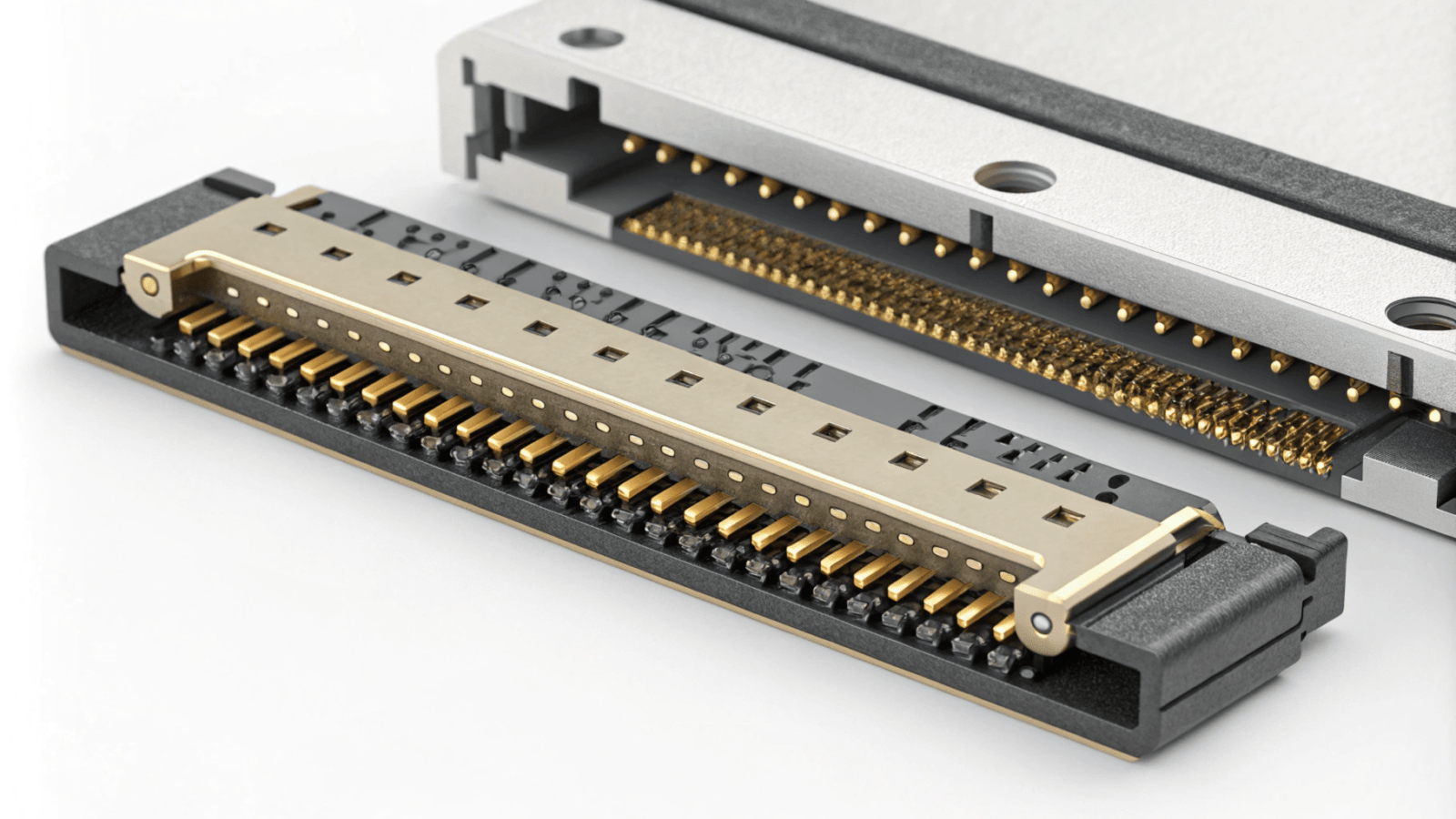

The latest developments in ZIF technology are focused on miniaturization, supporting higher data speeds, and increasing mechanical robustness for more demanding applications.

Trend 1: Miniaturization

Everything is getting smaller. This means connectors have to shrink too.

- Finer Pitch: We’ve moved from 1.0mm to 0.5mm as the standard. Now, 0.3mm and even 0.2mm pitch connectors are becoming more common in ultra-compact devices like smartwatches.

- Lower Profile: The height of the connector is also shrinking. A lower profile allows for thinner product designs. We now see connectors that are less than 1mm high.

Trend 2: High-Speed Data Transfer

It’s not just about power and simple signals anymore. Connectors now need to handle high-speed data protocols.

- Signal Integrity: At high speeds, things like impedance matching become critical. Connector designs are now optimized to handle protocols like MIPI (used for cameras and displays in phones) and LVDS (Low-Voltage Differential Signaling) with minimal signal degradation. This involves careful design of the contact shape and housing material(What Are the Differences Between LVDS and MIPI-DSI Interfaces?).

Trend 3: Increased Robustness and Reliability

As devices are used in more rugged environments, the connectors need to be tougher.

- Improved Locking Mechanisms: Designs like dual-sided contacts and stronger lock actuators provide better protection against shock and vibration. Some connectors now have metal “latch” features that reinforce the plastic lock for extra security.

- Higher Mating Cycles: A mating cycle is one instance of opening and closing the connector. Standard connectors are rated for about 20-30 cycles. More robust designs are being developed for applications where a module might be replaced or serviced multiple times.

I recently worked on a prototype for an industrial handheld scanner. The client needed a connector that was not only small (0.4mm pitch) but could also handle high-speed data from a camera and withstand being dropped. We used a new ZIF connector with a metal-reinforced lock. It’s this kind of evolution that keeps the industry exciting.

How Do You Choose the Right ZIF Connector for Your Application?

To choose the right ZIF connector, you must systematically evaluate your key requirements, including the cable pitch, pin count, physical orientation, and the electrical and environmental demands of your application.

Over the years, I’ve developed a mental checklist that I run through with every client to ensure we make the right decision.

My Selection Checklist

I always start with the most basic, non-negotiable points and work my way down to the finer details.

- 1. Cable Compatibility:

- Pitch: Does the connector pitch (e.g., 0.5mm) exactly match your FFC/FPC cable? This is the first and most important check.

- Cable Thickness: ZIF connectors are designed for a specific range of cable thicknesses (e.g., 0.3mm). Ensure your cable is within this range.

- 2. Physical and Mechanical Requirements:

- Pin Count: How many signals do you need to connect?

- Orientation: Do you need a vertical connector (cable inserts from the top) or a right-angle connector (cable inserts parallel to the board)? This is determined by your PCB layout and case design.

- Contact Position: Do you need top-contact or bottom-contact? This depends on which side of your FPC/FFC cable the exposed pads are on. Getting this wrong means there will be no connection.

- Actuator Type: Is a flip-lock or slider better for your assembly process and space constraints?

- 3. Electrical Requirements:

- Current Rating: What is the maximum current that each pin needs to carry? Standard ZIFs are for low-current signals, not for power lines.

- Voltage Rating: What is the maximum voltage?

- High-Speed Signals: Are you running MIPI, LVDS, or another high-speed protocol? If so, you need to look for a connector specifically designed for that.

- 4. Environmental Requirements:

- Temperature Range: What are the operating temperatures of your device?

- Vibration and Shock: Is this for a rugged device? If so, look for enhanced locking features.

Conclusion

Choosing and using a ZIF connector is simple when you understand the key features like pitch, actuator type, and material. They are the unseen heroes inside our favorite electronic devices.

FAQ

Can ZIF connectors handle high currents?

ZIF connectors typically handle low-current signals rather than high-power currents. For high-current needs, alternative connectors are recommended.

How many insertion cycles can a ZIF connector handle?

Most ZIF connectors can handle hundreds to thousands of insertion cycles, depending on quality and materials used.

Are ZIF connectors easy to damage?

ZIF connectors are designed to minimize cable damage, but improper handling or excessive force can cause harm. Always handle carefully.

What Happens If I Use an Incompatible Cable with a ZIF Connector?

Incompatible cables cause poor connections or damage. Always match cable thickness and width to connector specs.

Are There ZIF Connectors for High-Speed Data Transmission?

Yes, advanced ZIF connectors support high-speed data. Look for models with gold-plated contacts and low signal loss.