Ever find yourself squinting at your phone under the sun, or tilting your laptop screen to escape the glare from an overhead office light? That annoying reflection isn’t just a minor inconvenience. It can lead to tired eyes, headaches, and a frustrating user experience, especially when you need to see critical information clearly. You’re trying to work or navigate, but your own reflection is staring back at you, making the screen almost unreadable. The good news is, there’s a solution. By choosing the right screen coating, you can eliminate these visual disruptions and get a crystal-clear view every time.

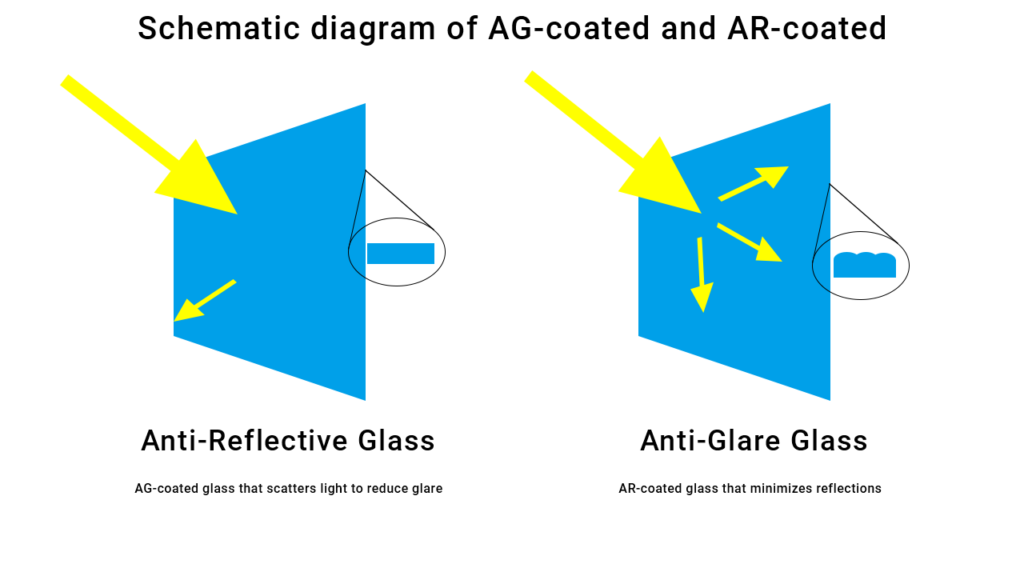

The main difference is how they handle light: anti-glare coatings use a diffused finish to scatter external light that hits a screen, while anti-reflective coatings have a specialized film that cancels out reflections from both external light and the light from the display itself.

As someone who’s been in the LCD module business for over 13 years, this is one of the most common points of confusion I see with my clients. People often use the terms interchangeably, but they are fundamentally different technologies with unique benefits. A client of mine, who owns a company that assembles bicycle displays, once faced a major issue with screen readability in direct sunlight. His customers couldn’t see their speed or navigation on a bright day. This forced us to dive deep into the specific optical properties his product needed. Understanding this distinction is the key to creating a product that performs flawlessly in the real world.

What Exactly Are Anti-Glare and Anti-Reflective Coatings?

Before you can choose the right solution for your display, you need to understand what each of these terms actually means. They both aim to improve your vision, but they get there in very different ways.

Anti-glare and anti-reflective coatings are not the same; anti-glare uses diffusion to scatter light, while anti-reflective coatings are designed to cancel out reflections, allowing more light to pass through the lens or display.

What is Anti-Glare?

An anti-glare (AG) coating is a surface treatment that uses diffusion to reduce the coherence of a reflected image. Think of it like frosted glass. It has a slightly roughened surface that scatters light instead of reflecting it directly back at your eyes. This makes it much easier to view a screen in very bright environments, like direct sunlight, because it breaks up the intense reflections that would otherwise obscure the display. So, while it combats external glare, it can slightly reduce the sharpness and clarity of the image on the screen.

What is Anti-Reflective?

An anti-reflective (AR) coating is a more complex, multi-layered coating applied to a surface to reduce reflections. Instead of just scattering light, it uses the principle of wave interference to cancel out light waves as they bounce off the surface. This means it can handle reflections from both the front (external light sources) and the back (light from the display itself) of the surface. The result is a much clearer, crisper image with higher light transmission, making the screen appear almost invisible.

Is Anti-Glare the Same as Anti-Reflective?

No, they are definitely not the same, though the terms are often confused. The core difference lies in their mechanism and result.

| Feature | Anti-Glare (AG) | Anti-Reflective (AR) |

|---|---|---|

| Mechanism | Scatters light with a rough surface (diffusion) | Cancels light waves with thin film layers (interference) |

| Primary Function | Reduces glare from external light sources | Reduces reflections from internal and external sources |

| Appearance | Matte or frosted finish | Appears clear or invisible |

| Image Clarity | Can slightly reduce sharpness | Maximizes sharpness and clarity |

In short, anti-glare manages reflections by making them blurry, while anti-reflective technology aims to eliminate them altogether.

How Do These Coatings Actually Manipulate Light?

It’s one thing to know their names, but I find that understanding how they work helps my clients make much better decisions. The science behind them is fascinating and directly impacts their performance.

Anti-glare coatings work by creating a rough surface to diffuse light, while anti-reflective coatings use thin, stacked layers of metal oxides to cause destructive light wave interference, effectively canceling out reflections.

Mechanism of Anti-Glare Coatings

The principle behind anti-glare is simple: diffusion. The surface of an AG coating is intentionally uneven on a microscopic level. When a strong, direct light source (like the sun or an overhead fluorescent bulb) hits this surface, the light rays don’t bounce back in a single, mirror-like direction. Instead, they are scattered in many different directions. This breaks up the harsh glare into a softer, less noticeable form, preventing it from overpowering the light being emitted by your display. It’s an effective, straightforward way to handle bright, external light sources.

Mechanism of Anti-Reflective Coatings

Anti-reflective coatings are far more high-tech. They consist of multiple, transparent, ultra-thin layers of metal oxides applied to the lens or display surface. Each layer has a different refractive index, which is a measure of how much it bends light. These layers are engineered with precise thicknesses. As light waves pass through the layers and reflect off each interface, the reflected waves are knocked out of phase with each other. This causes “destructive interference,” where the waves effectively cancel each other out. By neutralizing reflections this way, AR coatings allow more light to pass through directly to your eyes—up to 99.5% compared to about 92% for an uncoated surface.

Advanced Technologies

In my line of work at Hua Xian Jing, we often integrate these technologies to create custom solutions. For example, some modern displays use hybrid approaches. A device intended for both indoor and outdoor use might feature a base anti-glare layer to handle harsh sunlight, combined with an anti-reflective coating to preserve image clarity for indoor viewing. Furthermore, premium AR coatings often come bundled with other protective layers. Hydrophobic coatings repel water, while oleophobic coatings resist fingerprints and oils, making the display easier to clean. These advanced stacks are crucial for high-end applications in medical, military, and consumer electronics where performance and durability are non-negotiable.

Which Coating Performs Better for Visuals?

When my client was developing his bicycle displays, his main concern was visual performance. His customers needed to see their stats at a quick glance, in any lighting condition. This is where the differences between AG and AR become very practical.

For pure visual fidelity, anti-reflective coatings are superior. They allow more light to pass through and eliminate reflections, resulting in higher clarity, better contrast, and more vibrant colors than anti-glare coatings.

Clarity and Contrast

This is the biggest performance differentiator. Because anti-glare works by scattering light, it inherently introduces a small amount of haziness. This can slightly soften the image, reducing its sharpness and contrast. For general use, this is often an acceptable trade-off(What Does Contrast Ratio Mean on a Monitor?).

Anti-reflective coatings, on the other hand, are designed to maximize clarity. By eliminating reflections instead of just diffusing them, AR coatings allow a display to transmit the maximum amount of light with minimal distortion. This results in a sharper, more vibrant image with deeper blacks and brighter colors. With an AR coating, less than 0.5% of light might be reflected, compared to around 8% with an AG coating.

Eye Strain Reduction

Both coatings help reduce eye strain, but they do it in different ways. Anti-glare reduces the strain caused by fighting bright, external light sources. If you’ve ever worked on a laptop in a cafe by a window, you know this type of strain well.

Anti-reflective coatings also reduce this strain but go a step further. They eliminate the faint, ghost-like reflections on the screen’s surface that you might not even consciously notice. Your eyes are constantly trying to focus through these subtle reflections, which contributes to fatigue over long periods, especially for those of us who spend hours in front of a computer.

| Performance Metric | Anti-Glare (AG) | Anti-Reflective (AR) |

|---|---|---|

| Clarity & Sharpness | Good (some diffusion) | Excellent (maximum light transmission) |

| Contrast | Good | Excellent |

| Performance in Direct Light | Excellent (scatters harsh glare) | Good (can be overwhelmed by intense sources) |

| Performance in Low Light | Good | Excellent (maximizes available light) |

| Reduces Eye Strain | Yes, from external glare | Yes, from all reflections |

Where Should You Use Anti-Glare vs. Anti-Reflective?

Choosing the right coating depends entirely on the product’s environment. There is no single “best” choice for everything. It’s about matching the technology to the application.

Anti-glare is ideal for rugged, outdoor devices exposed to direct sunlight, while anti-reflective is perfect for high-end indoor displays, photography, and situations where visual clarity is the top priority.

Anti-Glare Applications

I typically recommend AG coatings for devices that will be used in bright, uncontrolled lighting environments. The diffusion method is incredibly effective at making a screen readable under direct sunlight or harsh industrial lighting.

- Outdoor and Marine Devices: GPS units, fish finders, and vehicle displays.

- Industrial Control Panels: Screens used in brightly lit factories or outdoor settings.

- Public Kiosks and ATMs: Displays that need to be legible from various angles in public spaces.

Anti-Reflective Applications

For applications where image quality is paramount, AR is the only way to go. Its ability to produce a crystal-clear, reflection-free image is unmatched.

- High-End Electronics: Smartphones, tablets, laptops, and 4K TVs where users expect vivid colors and sharp details.

- Medical Imaging Displays: Screens used for diagnostics where every detail matters.

- Retail and Museum Displays: Showcasing products or art without distracting reflections from overhead lights.

- Optical Lenses: Eyeglasses and camera lenses benefit greatly from AR coatings to reduce glare and improve cosmetic appearance.

Hybrid Coatings

For some of our clients at Hua Xian Jing, a standard solution just won’t cut it. A device might need to be used both in an office and out in the field. In these cases, we can explore hybrid solutions. This might involve a light anti-glare etch combined with a multi-layer AR coating. This approach aims to provide a balance: good performance in bright outdoor light without sacrificing too much indoor clarity. These custom solutions are part of our LCD ODM/OEM service and are essential for creating truly versatile products.

What Are the Trade-Offs Between These Two Options?

As with any engineering decision, you can’t have it all. When choosing between AG and AR, you have to consider the trade-offs, which usually come down to two things: cost and durability.

The primary trade-off is cost versus performance; anti-glare is a cheaper, more durable solution, while anti-reflective offers superior optical quality at a significantly higher price point.

Cost Analysis

This is often the deciding factor for many projects.

- Anti-Glare: AG is a relatively inexpensive process. Since it’s typically a mechanical or chemical etching of the surface, it doesn’t require the complex machinery and vacuum deposition chambers that AR coatings do. It adds minimal cost to the final display module.

- Anti-Reflective: AR coatings are substantially more expensive. Applying multiple, microscopically thin layers of material in a vacuum is a precise and time-consuming process. A premium AR coating can cost anywhere from $50 to $100 extra for a pair of eyeglasses, and the cost scales for larger displays. The quality can vary significantly, with premium coatings taking days to apply correctly in a lab.

Durability and Wear

The physical nature of these coatings affects how they hold up over time.

- Anti-Glare: Since an AG finish is part of the glass or plastic surface itself (an etched texture), it is very durable. It can’t peel or scratch off. This makes it a great choice for touchscreens and devices that will be handled frequently or used in harsh environments.

- Anti-Reflective: AR coatings are additive layers on top of the surface. While modern premium coatings are quite hard and scratch-resistant, they can still be damaged. A deep scratch can compromise the coating, and lower-quality AR coatings have been known to peel or wear off over time, especially with improper cleaning. However, many high-end AR coatings now include a hardcoat layer to enhance their durability and extend the life of the lens or display.

How Do They Benefit Eye Health and Comfort?

Beyond just seeing an image clearly, these coatings play a direct role in our visual comfort. As we spend more of our lives looking at screens, this has become a critical consideration for product designers(Eye-Friendly Display: Is IPS Good for Watching Shows?).

Both coatings significantly reduce eye strain by managing how light interacts with the screen, but anti-reflective coatings offer a broader range of comfort by eliminating subtle, fatiguing reflections that anti-glare can’t address.

Reducing Eye Strain

Your eyes are constantly working to process visual information. When that information is disrupted by glare or reflections, your eye muscles have to work harder.

- Anti-Glare primarily helps by mitigating the need to squint or strain in response to bright, external light sources. It calms the visual field, allowing your eyes to relax.

- Anti-Reflective coatings reduce eye strain by creating a clearer, more restful viewing experience. They eliminate distracting reflections from all sources, allowing your eyes to focus on the content itself without subconscious effort. This is especially beneficial during prolonged screen use, such as working on a computer all day.

Additional Health Considerations

The conversation around eye health and screens has expanded in recent years. While AG and AR coatings are designed to manage reflections, they are often part of a larger system of optical wellness. For instance, many premium AR coatings for eyeglasses can be combined with other technologies that address different concerns. It’s important to see these coatings as one tool in a comprehensive approach to visual health, rather than a single solution for all eye-related issues.

How Do They Compare to Other Optical Technologies?

AG and AR are not the only players in the game. It’s helpful to understand how they fit in with other common optical technologies that my clients often ask about.

While anti-glare and anti-reflective coatings manage reflections, technologies like blue light filters and polarized lenses serve entirely different purposes by selectively blocking specific types of light before they even reach the surface.

Anti-Glare vs. Blue Light Filters

This is a common point of confusion.

- Anti-Glare/Anti-Reflective: These manage all visible light reflecting off the surface of a display. Their goal is to improve clarity and reduce glare.

- Blue Light Filters: These are designed to specifically block or absorb a portion of the high-energy visible (HEV) blue light emitted from digital screens. The goal is to reduce potential eye strain and sleep cycle disruption associated with blue light exposure. A display can have an AR coating and a blue light filter simultaneously.

Anti-Glare vs. Polarized Lenses

People often associate anti-glare with sunglasses, and this is where polarization comes in.

- Anti-Glare Coating: A surface treatment that diffuses light.

- Polarized Lenses: These are different. They contain a special filter that blocks horizontally polarized light. This is the type of intense, blinding glare that reflects off flat surfaces like a wet road, water, or a car hood. While the term “anti-glare glasses” is often used to describe polarized sunglasses, the technology is fundamentally about blocking specific light waves, not diffusing them at the surface.

Anti-Fingerprint and Anti-Fog Coatings

These are additional functional coatings that are often bundled with high-end AR treatments.

- Oleophobic (Anti-Fingerprint) Coatings: As mentioned, these create a surface that repels oil, making it easy to wipe away fingerprints and smudges. This is crucial for touchscreens.

- Hydrophobic (Anti-Fog) Coatings: These repel water, causing droplets to bead up and roll off instead of smearing and obstructing vision. This is useful for eyeglasses and camera lenses used in humid or rainy conditions(How is Waterproof Touch Functionality Achieved in LCD Devices?).

How Do I Choose the Right Coating for My Needs?

To choose the right coating, you must first assess the primary use environment and prioritize between clarity and glare reduction; then, weigh that decision against your budget and durability requirements.

Assessing Your Needs

Start by asking these questions:

- Where will the display be used most? If the answer is outdoors in direct sunlight, lean towards anti-glare. If it’s indoors or in mixed lighting where image quality is key, anti-reflective is likely the better choice.

- What is the most important visual factor? If it’s eliminating harsh glare, choose AG. If it’s maximum clarity, sharpness, and color vibrancy, choose AR.

- Is it a touchscreen? The superior durability of an AG finish often makes it a better choice for devices that will be touched constantly. However, premium AR coatings with hardcoats can also be very durable.

Cost and Accessibility

As a business owner sourcing components, I know that budget is always a factor. You need to balance the ideal user experience with the cost of production.

- For budget-conscious projects or rugged applications: Anti-glare offers excellent value and performance where it matters most.

- For premium products where user experience is a key selling point: Investing in a high-quality anti-reflective coating is often worth the extra cost. It elevates the product and provides tangible benefits in clarity and comfort.

At Hua Xian Jing, we provide free prototype designs so our clients can test these options in the real world. Getting a sample in your hands is the best way to see the difference for yourself and make a final, confident decision. A bulk production run can be ready in as little as 30 days once you’ve made your choice.

Conclusion

Navigating the world of display coatings doesn’t have to be complicated. While the terms “anti-glare” and “anti-reflective” are often mixed up, they represent two distinct technologies with clear strengths. Anti-glare is your workhorse for battling bright, external light through diffusion, making it perfect for rugged outdoor use. Anti-reflective is your precision tool for achieving the highest level of visual clarity by eliminating reflections, ideal for high-end electronics and indoor applications.

The right choice always comes back to your specific needs and priorities—balancing performance, environment, and cost. By understanding these key differences, you can make an informed decision that ensures your display is not just visible, but perfectly clear and comfortable to use, no matter where it’s viewed.

Related Articles:

What Special Requirements Do Medical LCD Panels Have?

Why Do Some TFT LCDs Require Custom Driver Software?

How Are LCD Modules Secured Against Vibration?

How Do Sunlight-Readable LCDs Maintain Contrast Outdoors?

How do different backlight technologies affect color temperature control?

FAQ

Can anti-glare or anti-reflective coatings be added to any existing display?

Some films and sprays are available, but for best results, it is best to use factory-applied coatings during the manufacturing process.

Will anti-glare or anti-reflective coatings affect touch screen sensitivity?

Most modern coatings are designed to maintain full touch sensitivity, but very thick or poor-quality coatings may reduce accuracy slightly.

Do these coatings wear off over time?

With normal use, high-quality coatings can last for years, but frequent cleaning with abrasive materials can shorten their lifespan.

Can anti-glare or anti-reflective coatings be combined with other protective features?

Yes, coatings can be combined with anti-fingerprint, anti-fog, and blue light filter technologies to improve both durability and user comfort.

Are there environmental impacts from these coatings?

Anti-reflective coatings may use more complex materials, but both are safe. Our factory ensures eco-friendly production processes.