HDMI moves raw, uncompressed audio-video over a robust cable, while MIPI DSI trims pin-count and power by serializing display data across slim differential pairs—making each interface excel in different design scenarios.

My earliest projects taught me that dropping the wrong interface into the wrong product can sink BOM budgets, derail EMC approvals, or hamstring future upgrades.

Technical Comparison of HDMI and MIPI DSI?

HDMI and MIPI DSI stem from vastly different design philosophies, so I always begin by mapping their electrical, protocol, and bandwidth characteristics side by side.

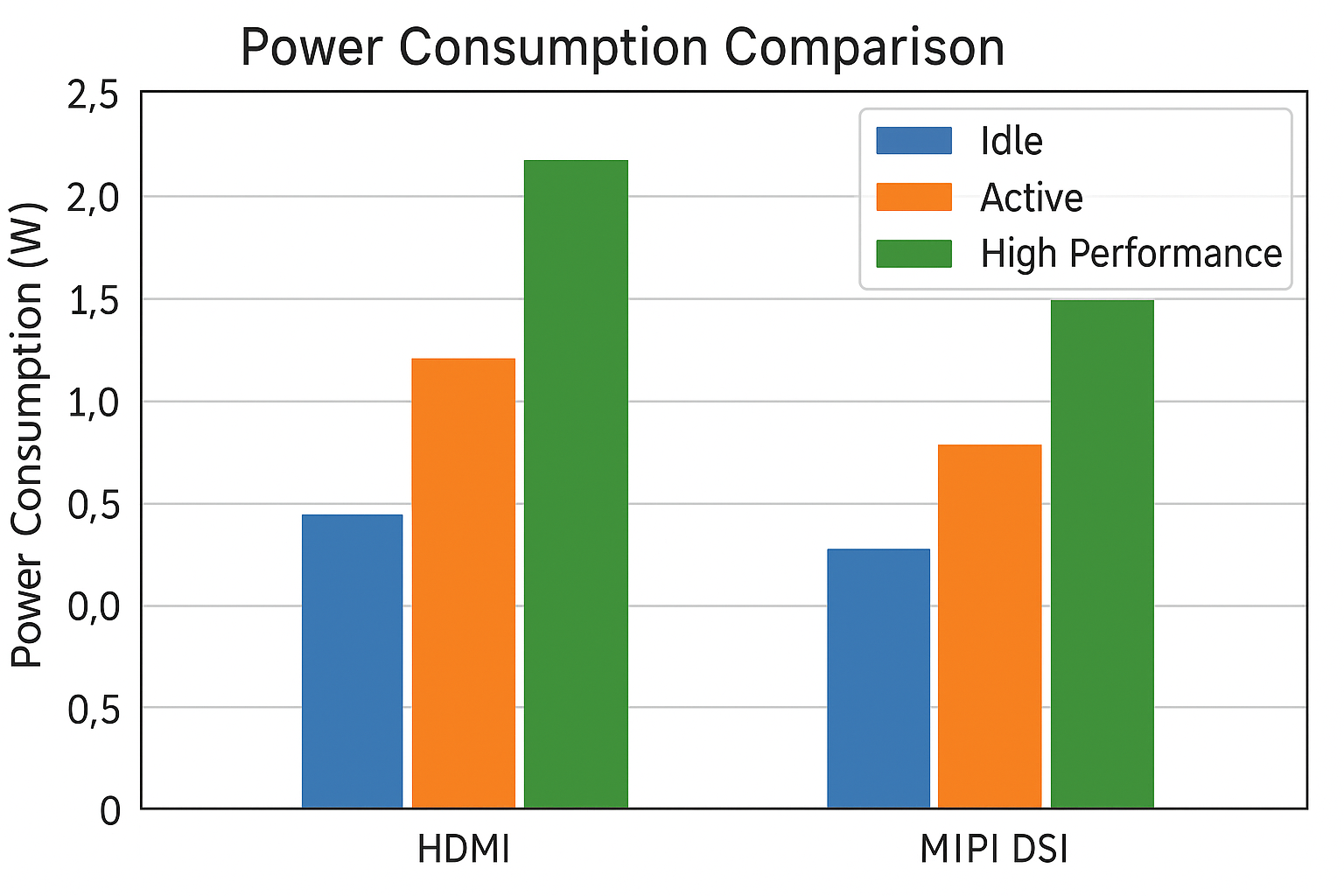

HDMI delivers up to 96 Gbps in Version 2.2 using four FRL lanes, whereas MIPI DSI-2 v2.2 pushes 6+ gigapixels per second through configurable C-PHY or D-PHY links, often consuming less than half the power per bit.

Physical-Layer Snapshot

| Interface | Lane Count | Max Raw Bandwidth | Signaling Swing | Typical Connector Pins | Power Focus |

|---|---|---|---|---|---|

| HDMI 2.2 | 4 FRL lanes | 96 Gbps | 3.3 V TMDS/FRL | 19 pins (Type A) | Cable-powered active option draws up to 300 mA |

| MIPI DSI-2 v2.2 | 4 D-PHY or 3 C-PHY “trios” | 6 + Gpx/s (>80 Gbps equiv) | 200 mV–1.2 V differential | 26-40 flexible PCB pads (custom FPC) | LP and ULP idle states cut consumption by >90% |

The high swing of HDMI’s TMDS/FRL lines simplifies longer cable runs but ramps up EMI radiation above 142 MHz harmonics, whereas MIPI’s low-voltage differential signaling keeps emissions well below regulatory limits, easing enclosure shielding.

Protocol Control

HDMI treats the display as a “dumb” sink: timing, blanking, and color depth arrive strictly as pixel streams. MIPI builds a richer command channel (DCS + MCS) that lets me tweak gamma or enter standby without extra GPIOs(How Does Signal Timing Impact LCD Image Stability?).

Which Applications Are Best for HDMI vs. MIPI DSI?

Now that we understand the technical side, let’s talk about where each interface truly shines. Matching the interface to the application is key for a successful product design.

HDMI is ideal for consumer electronics like TVs, monitors, and projectors that require a simple, standard external connection. MIPI DSI excels in embedded systems like smartphones, tablets, and automotive infotainment displays.

I once worked with a client, who was developing a new smart home hub. He initially planned to use HDMI internally because his team was familiar with it. I showed him how MIPI DSI would reduce the product’s size, cost, and battery consumption. He was hesitant at first, but switching was the best decision for that product(What Are the Parts of a Smart Home?).

| Scenario | Screen Size | Preferred Interface | Rationale |

|---|---|---|---|

| TV | 80 inch | HDMI 2.1/2.2 | 48–96 Gbps uncompressed, consumer cable standard |

| Industrial HMI Panel | 7 inch IPS | Either (HDMI if remote, DSI if on-board) | Evaluate enclosure cables vs. EMC margin |

| In-car 12.3″ Cluster | 1920 × 720 | MIPI DSI-2 + A-PHY bridge | Low-EMI, functional-safety extensions (MIPI DSE) |

When to Choose HDMI

HDMI is the king of external connections. Its design philosophy is all about interoperability and ease of use for the end-user.

- Consumer Electronics: Think televisions, Blu-ray players, gaming consoles, and desktop monitors. The plug-and-play nature is essential here.

- Digital Signage: The ability to run long cables reliably makes HDMI perfect for commercial displays in airports, malls, and restaurants.

- Presentation Systems: In conference rooms and classrooms, the universal adoption of HDMI on laptops and projectors makes it the only practical choice.

When to Choose MIPI DSI

MIPI DSI was born from the need for a high-performance, low-power interface inside mobile devices. It’s built for efficiency and compactness.

- Mobile Devices: Smartphones and tablets are the classic use case. Every component is optimized for battery life and a small footprint, which is where MIPI DSI wins.

- Automotive Displays: The instrument cluster and infotainment system in modern cars often use MIPI DSI because of its low EMI and robustness in electronically noisy environments.

- Industrial and Medical Devices: For handheld diagnostic tools or portable factory controllers, MIPI DSI provides the necessary performance without draining the battery.

How Can You Maximize Display Performance and Quality?

Once the interface is implemented, the job isn’t done. You need to optimize the settings to get the best possible image quality and performance from your display.

For HDMI, this involves ensuring EDID data is correctly read to set the right resolution and timing. For MIPI DSI, optimization focuses on configuring the burst modes and command sequences for the specific display panel.

I’ve seen beautiful, expensive displays show a terrible image because of simple software configuration errors. The final optimization stage is what separates a mediocre product from a great one.

Optimizing HDMI Performance

- EDID Management: Extended Display Identification Data (EDID) is how the display tells the source device (like a PC) what resolutions and refresh rates it supports. Ensure your system correctly reads and interprets this data to output a compatible signal.

- Color Space: HDMI supports various color spaces like RGB and YCbCr. For PC content, RGB Full Range usually provides the best quality. For video content, YCbCr might be better. Mismatches can lead to washed-out or crushed colors.

Optimizing MIPI DSI Performance

- Burst Mode vs. Non-Burst Mode: MIPI DSI can send data in bursts. This allows the high-speed physical layer to be turned off between packets, saving a significant amount of power. Configuring this correctly is crucial for battery life.

- Display Command Set (DCS): MIPI DSI has a standardized set of commands for controlling display functions like brightness, contrast, and gamma. You need to send the correct initialization sequence to the display on startup to configure it properly. This sequence is unique to each display model and is found in its datasheet.

Performance and Quality Optimization?

Do you need HDR10+ at 4 K 240 Hz, or will 60 Hz suffice? I juggle three levers—compression, lane count, and clock rate—to squeeze bitrate without degrading visuals.

HDMI 2.2 can drive uncompressed 4 K 240 Hz 12-bit 4:4:4 if the Ultra96 cable is used, whereas DSI-2 lets me halve lane count by enabling VESA DSC 1.2, transmitting 4 K 120 Hz in 4 lanes at 4.4 Gbps each with visually lossless results.

Bit-Budget Scenarios

| Mode | Pixels/s | Raw Mbps Needed | HDMI Lanes Needed | DSI Lanes Needed (w/ DSC) |

|---|---|---|---|---|

| 4 K 120 Hz 10-bit 4:4:4 | 49.7 Gpx/s | 99.3 Gbps | 4 FRL (48 Gbps each, DSC likely) | 4 D-PHY @ 1.1 Gbps (compressed) |

| 8 K 60 Hz 10-bit 4:4:4 | 98.7 Gpx/s | 197.4 Gbps | 4 FRL + DSC | 6 C-PHY trios @ 2.9 Gsym/s (DSC) |

| 1080p 240 Hz 8-bit | 12.4 Gpx/s | 24.8 Gbps | 3 TMDS lanes (HDMI 2.0) | 2 D-PHY @ 1.5 Gbps (raw) |

Compression, when paired with proper display support, yields measurable battery gains—my tests on a 7-inch portable meter saw a 15% runtime boost by toggling DSC at 60 Hz.

Compatibility and Integration Challenges?

No one enjoys the “black screen of HDCP.” I learned to pre-empt five recurring pitfalls: power budgeting, hot-plug timing, signal mapping, HDCP/DSC IP costs, and EMI(What EMI/EMC Rules Must Automotive LCD Displays Follow?).

HDMI sources must supply up to 300 mA over pin 18 for active cables, while MIPI LS modes draw microamps; forgetting this delta often fries bench supplies or causes boot brown-outs.

Common Trouble Tickets

| Symptom | Likely Cause | Quick Fix |

|---|---|---|

| Random dropouts after 6 ft cable | FRL lane error from marginal eye pattern | Swap for certified Ultra High Speed cable; reduce link-rate |

| “Link err” in D-PHY analyzer at LP→HS switch | Missing 10 nF plane-change caps | Add return-path caps near vias |

| HDCP-2.3 auth fails on new monitor | Wrong key revocation list | Update source firmware; retest with sink-side keys |

| EMI fail at 65 MHz & 130 MHz peaks | HDMI pixel clock harmonic | Lower pixel clock or add common-mode chokes |

| White noise snow on VR HMD | DSC slice grouping mis-matched | Verify PPS send at boot per VESA spec |

Are HDMI and MIPI DSI Ready for Future Tech?

Both interfaces are continuously evolving. HDMI is pushing towards higher resolutions like 8K and beyond for consumer media, while MIPI DSI is focusing on higher efficiency and new features for next-generation embedded displays.

The Future of HDMI

The latest standard, HDMI 2.1, already supports features like 8K resolution at 60Hz and Dynamic HDR. The future focus will likely be on even higher data rates to support 10K resolutions and advanced gaming features like Variable Refresh Rate (VRR).

The Future of MIPI DSI

The MIPI Alliance is constantly improving its specifications. The DSI-2 standard supports higher resolutions and includes features like VESA Display Stream Compression (DSC) to transmit ultra-high-definition video over fewer lanes, which saves power and cost. Future versions will likely focus on even greater power efficiency and integration with other sensors, catering to the demands of AR/VR and advanced automotive systems.

Conclusion

Choosing between HDMI and MIPI DSI depends entirely on your application. Use HDMI for external connections and MIPI DSI for internal, power-sensitive designs.

Related Articles:

How Do You Drive Transflective LCD Modes Successfully?

How is Parity Error Detection in LCD Frame Buffers Tested During Memory Stress?

How can I reduce LCD power consumption in embedded systems?

How Does SPI Enable Reliable Communication with LCD Modules?

How Can You Program a Graphic LCD Module to Show Custom Graphics?

FAQ

Can HDMI and MIPI DSI be used interchangeably?

No, they serve different purposes. HDMI is for high-resolution displays, while MIPI DSI suits compact, low-power devices.

What are the cost implications of choosing HDMI over MIPI DSI?

HDMI involves licensing fees and more expensive hardware. MIPI DSI is cost-effective for small-scale, low-power designs.

How do I choose between HDMI and MIPI DSI for a custom display?

Assess your project’s resolution, power needs, and size. HDMI fits large screens; MIPI DSI suits mobile devices.

Are there alternatives to HDMI and MIPI DSI?

Yes, USB-C and DisplayPort are emerging options. They offer flexibility but may require additional hardware.

How do I ensure long-term support for my interface choice?

Check chipset availability and industry trends. Flexible designs, like modular setups, ensure future compatibility.