M12 connectors are built into industrial displays by mounting them directly into device housings or attaching them via shielded cable assemblies. Their 12-mm threaded lock ensures a secure connection, even in high-vibration settings like robotic arms or conveyor systems.

These connectors come in codings like A, B, and D to prevent mismating. For example, A-coding handles power and basic signals, while X-coding supports 10 Gb/s Ethernet for high-speed data displays. Pin counts vary: 4- or 8-pin setups manage Ethernet communication, while 3-pin versions power smaller screens.

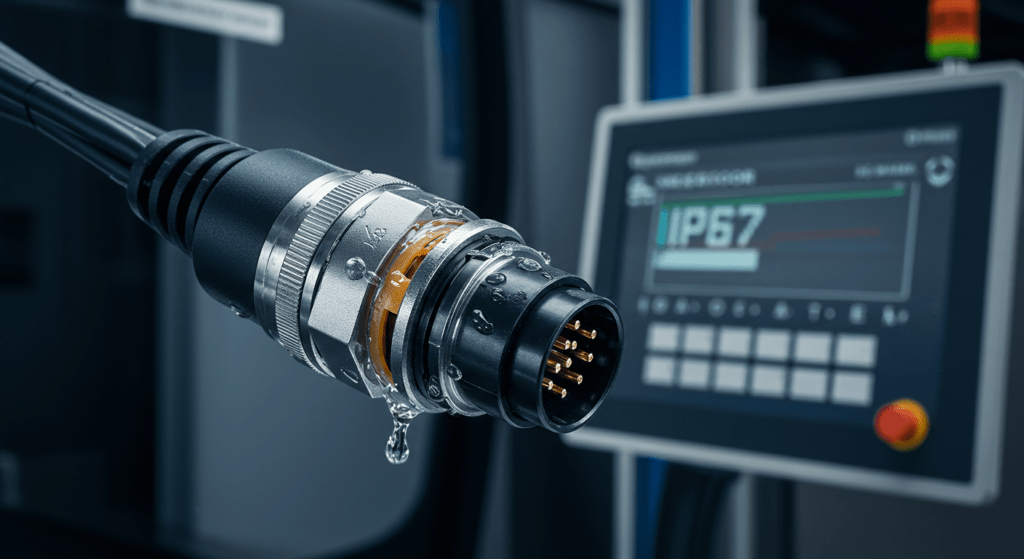

Industrial displays with M12 connectors achieve IP67/68 ratings, blocking dust and water ingress in outdoor or washdown environments. Shielded designs with 360° EMI protection maintain signal clarity for touchscreens and control panels.

M12 hybrids combine Single Pair Ethernet (SPE) and power in one interface, simplifying wiring for compact displays under the IEC 63171-7 standard. This lets screens transmit data and receive electricity through a single cable, reducing clutter.

In automation, M12-linked displays connect to PLCs via protocols like Profinet or EtherNet/IP. Their standardized pinouts ensure compatibility across brands, easing repairs or upgrades. For example, a 5-pin A-coded M12 can relay CANbus signals to a diagnostic display panel.

Modular M12 systems allow quick swaps of display modules without rewiring. RAFI’s designs use color-coded connectors to simplify maintenance in control cabinets or machinery HMI panels.

What Makes M12 Connectors Essential in Industrial Settings?

M12 connectors are circular electrical connectors featuring a 12 mm locking thread, standardized under IEC 61076-2-101. They are vital in industrial environments because of their durability, compact size, and ability to handle power, data, or both. These qualities make them a reliable choice for automation, control systems, and harsh conditions where dust, vibration, and moisture are common.

Why Are M12 Connectors So Valuable?

In industrial settings, equipment needs to perform consistently under challenging conditions. M12 connectors shine here due to their rugged design—they resist wear and tear while maintaining secure connections. Their small size allows them to fit into tight spaces, a critical advantage in crowded machinery or compact devices. Plus, with options to transmit power, data, or a mix of signals, they adapt to a wide range of applications, from powering sensors to enabling high-speed communication.

Take a factory floor as an example: sensors tracking machine performance might use 5-pin A-coded M12 connectors, while an Ethernet network linking production units could rely on D-coded or even X-coded variants for speeds up to 10 Gbps. This flexibility reduces the need for multiple connector types, simplifying design and maintenance.

Breaking Down the Technical Specs

Here’s a closer look at what sets M12 connectors apart:

- Standard: Governed by IEC 61076-2-101, ensuring they work seamlessly across global systems.

- Pin Configurations:

- 4-pin: Perfect for basic power or simple signals.

- 5-pin: Widely used for sensors and actuators.

- 8-pin: Handles mixed power and data tasks.

- 12-pin: Built for complex data transmission.

- Coding Types:

- A-coded: Ideal for sensors and actuators.

- D-coded: Supports industrial Ethernet connections.

- X-coded: Designed for high-speed data (e.g., Amphenol M12 X coding hits 10 Gbps).

- Key Benefits:

- Durability: Stands up to tough environments.

- Compact Size: Saves space without sacrificing performance.

- Versatility: One connector, multiple uses.

These features make M12 connectors a go-to solution for industries like manufacturing, automotive, and robotics.

How Do M12 Connectors Stay Compatible?

M12 connectors use specific coding—like A, D, and X—to prevent mix-ups. An A-coded plug won’t fit a D-coded socket, which stops power lines from crossing with data lines by mistake. This built-in safety is a big deal in setups with lots of interconnected devices, cutting down on errors and downtime. Standardization under IEC 61076-2-101 also means they play nice with equipment worldwide, making them a dependable choice for engineers everywhere.

How Are M12 Connectors Physically Implemented in Industrial Displays?

M12 connectors are physically implemented in industrial displays through panel-mounted or cable-mounted designs, integrated with pre-drilled ports on the display housings, and secured using threaded connections to ensure durability and reliability in harsh environments.

In industrial displays, the choice between panel-mounted and cable-mounted M12 connectors depends on the specific application requirements. Panel-mounted designs offer a more secure and compact solution, while cable-mounted designs provide greater flexibility in terms of cable management and replacement.

Technical Details of Mounting and Housing Integration

Mounting Methods:

- Panel-mounted M12 connectors are directly attached to the display housing, providing a fixed and stable connection.

- Cable-mounted M12 connectors are connected via cables, allowing for easier replacement and maintenance.

Mechanical Specifications:

- The M12 thread pitch is typically 1.0 mm, ensuring a tight and secure connection.

- The M12 thread dimensions are standardized, with a nominal diameter of 12 mm and a pitch of 1.0 mm.

Special Features:

- M12 quick disconnect to dual M8 allows for easy disconnection and connection of multiple devices.

- Integrated quick-disconnect mechanisms facilitate rapid maintenance and replacement.

Technical Details of Cable and Connection Management

Cable Types and Configurations:

- M12 cables are available in various configurations, including 4-pin, 5-pin, 8-pin, and 12-pin variants.

- M12 to standard cable configurations allow for compatibility with different types of connectors and devices.

Connector Adapters and Angles:

- M12 4-pin right angle adapters are used in space-constrained areas to change the cable direction.

- Milwaukee M12 adapters are specialized for specific tools but share similar functionality.

Securing the Connection:

- Threaded designs ensure robust, vibration-resistant, and watertight connections, typically achieving an IP67 rating.

Electrical Implementation and Wiring

M12 connectors are widely used in industrial displays for their ability to provide reliable electrical implementation and wiring solutions. They achieve this through standardized pin configurations, color-coded wiring schemes, and the capacity to handle both power and data transmission within a single connector. This section explores the pin configurations, wiring standards, and the integration of power and data functionalities, along with best practices for ensuring robust connections.

Pin Configuration and Wiring Schemes

M12 connectors come in various pin counts, each designed to meet specific electrical and functional requirements in industrial displays. Their standardized pinouts and wiring schemes simplify installation and ensure signal integrity.

Detailed Pinout Configurations

- 4-Pin Connectors: Commonly used for basic power delivery or simple data signals. For example, a typical M12 4-pin connector might assign pins for positive voltage, ground, and two signal lines.

- 5-Pin Connectors: Offer additional functionality, such as an extra pin for shielding, which enhances protection against electromagnetic interference.

- 12-Pin Connectors: Support complex signal distributions, making them ideal for applications requiring multiple data channels or combined power and signal lines (e.g., Molex 12-pin configurations).

These pinout configurations are standardized across industries, ensuring compatibility and reducing the likelihood of wiring errors during installation.

Color Coding and Wiring Standards

To maintain consistency and accuracy, M12 connectors use standardized color codes for wiring:

- M12 4-Pin Color Code: Typically includes brown for +24V, blue for 0V (ground), black for signal 1, and white for signal 2.

- M12 5-Pin Color Code: Adds a gray wire, often used for shielding or an additional signal.

- M12 Wire Colors for Higher Pin Counts: Follow similar conventions, with additional colors like yellow, green, or pink assigned to specific pins based on the connector’s purpose.

These color-coding standards ensure correct wiring, minimize mistakes, and uphold signal integrity, which is critical in industrial environments where reliability is paramount.

Data Transmission and Power Supply

M12 connectors are versatile, capable of managing both power and data transmission within a single unit. This dual functionality makes them a popular choice for industrial displays, where efficient use of space and robust performance are essential.

Data vs. Power Signal Distribution

- Power Supply: M12 connectors can deliver 12V or 24V DC to power industrial displays or related equipment. For example, a 4-pin connector might dedicate two pins to power (e.g., +24V and ground) and two to signals.

- Data Transmission: The same connector can carry data signals, such as sensor outputs or communication protocols, alongside power. This eliminates the need for separate connectors, simplifying system design.

Specialized Data Applications

- M12 Ethernet Connector: Designed for high-speed data transmission, these connectors support industrial Ethernet networks (e.g., PROFINET or EtherCAT). They typically use 4-pin or 8-pin configurations to handle data rates up to 10 Gbps.

- M12 to RJ45 Bulkhead: This adaptation allows M12 connectors to interface with standard Ethernet cables, integrating industrial displays into broader network systems seamlessly.

These specialized applications highlight the adaptability of M12 connectors in meeting the demands of modern industrial data networks.

Electrical Connection Details

For reliable performance, M12 connectors rely on robust electrical connections:

- M12 Electrical Connection: Achieved through secure wiring practices that prevent signal loss or power interruptions.

- M12 Crimp Methods: Crimping is a preferred technique for attaching wires to M12 pins. Using a ratchet crimping tool, technicians apply consistent pressure to create a firm, durable connection that withstands vibration and environmental stress.

These practices ensure long-lasting connections, reducing downtime and maintenance costs in industrial settings.

What Are the Advanced Technical Details and Variants of M12 Connectors?

M12 connectors come in various coding systems, genders, and specialized designs, with specific tools and techniques required for proper installation. These variants and details ensure compatibility, reliability, and ease of use in industrial applications.

M12 connectors are highly adaptable, with coding systems like A-coded, D-coded, and X-coded preventing misconnection—a feature that can save significant downtime costs in complex setups. Gender differences, such as male and female connectors, cater to specific device and cable needs, while specialized designs like field wireable options offer on-site flexibility. This versatility makes M12 connectors a staple in industries ranging from automation to high-speed data networks.

Connector Types and Special Features

Variations in Coding and Gender:

- A-coded: Commonly used for sensors and actuators, supporting basic power and signal needs.

- D-coded: Built for Ethernet networks, handling data rates up to 100 Mbps.

- X-coded: Designed for high-speed applications, such as 10 Gbps, with examples like Amphenol M12 X-coded connectors.

- Male Connectors: Feature pins (e.g., M12 male connector) and connect to devices.

- Female Connectors: Have sockets (e.g., M12 female connector) and pair with cables.

Specialized Designs and Field Wireable Options:

- Field Wireable M12 Connectors: Allow custom assembly on-site, perfect for unique setups or repairs.

- Pre-assembled Connectors: Factory-made (e.g., M12 in standard or M-12 connector), offering tested reliability but less adaptability.

Comparative Analysis: M8 vs. M12 Connectors:

- Size: M8 connectors (8 mm thread) are compact; M12 connectors (12 mm thread) support more connections.

- Pin Count: M8 offers 3-4 pins, while M12 provides up to 12 pins.

- Preference: Use M8 for small sensors; choose M12 for higher power or signal demands.

Why Is Proper Installation Crucial for M12 Connectors?

Proper installation ensures reliable connections, prevents damage to connectors and cables, and maintains signal integrity in industrial environments.

A poorly installed M12 connector can result in loose fits or signal loss, disrupting operations and increasing maintenance costs. Techniques like crimping and the use of pre-assembled cables streamline the process, ensuring durability and performance even under harsh conditions like vibration or moisture exposure.

Installation Tools and Techniques

Crimping and Assembly Tools:

- M12 Crimp Tools: Secure wires to connectors (e.g., M 12 tools), reducing the chance of disconnection in high-vibration settings.

- Proper crimping strengthens the bond, enhancing longevity.

Cable and Connector Integration:

- Pre-assembled Cables: Options like IFM M12 cable are ready-to-use, cutting installation time and ensuring consistency.

- Match cable length to the setup to avoid strain or excess slack in the M12 connector cable assembly.

How Do M12 Connectors Perform in Real-World Industrial Applications?

M12 connectors excel in industrial settings due to their durability and ability to handle tough conditions like dust, water, and vibration. They are widely used in factory automation, transportation, and embedded systems, ensuring reliable connections for industrial displays.

These connectors are designed to thrive where others might falter, offering secure and consistent performance in challenging environments. Their robust construction and specialized features make them a go-to solution for engineers needing dependable connectivity in industrial applications.

- Sealing: Rated IP65/IP67, M12 connectors protect against dust ingress and can endure water immersion up to 1 meter for 30 minutes, ideal for harsh industrial conditions.

- Mounting: Their sturdy design resists loosening from vibration, maintaining tight connections in dynamic settings.

- Installation: Proper torque—typically 0.6 Nm for standard M12 connectors—ensures a secure fit during setup.

- Maintenance: Routine inspections every 6 months help detect corrosion or wear early, prolonging connector life.

Real-World Applications

- Factory Automation: A 5-pin A-coded M12 connector connects industrial LCDs to PLCs, delivering stable communication in electrically noisy environments like manufacturing floors.

- Transportation and Outdoor Monitoring: An 8-pin X-coded M12 connector supports high-speed data streaming at 10 Gbps and powers rugged displays, performing reliably in extreme weather or mobile setups.

- Embedded Systems: With precise M12 connector dimensions (e.g., 12 mm thread) and dependable wiring, they integrate seamlessly into compact LCD systems, ensuring consistent operation.

How to Choose the Right M12 Connector for Your Application?

Ensuring the Best Fit

Choosing the right M12 connector requires aligning the pin count and coding with your specific needs. For example:

- A 4-pin A-coded connector suits basic power delivery.

- An 8-pin X-coded variant handles high-speed data tasks effectively.

Additional Considerations

- Confirm environmental ratings (e.g., IP67) match your operational demands, such as water or dust exposure.

- Match the connector’s coding (A-coded, D-coded, X-coded, etc.) to your equipment to prevent compatibility issues.

- In high-vibration environments, select connectors with anti-vibration features or extra locking mechanisms for added security.

FAQ

What are the main differences between A-coded and X-coded M12 connectors in industrial display interfaces?

A-coded M12 connectors are commonly used for power and sensor applications, while X-coded M12 connectors support high-speed Ethernet (up to 10 Gbps) for industrial networking and real-time data transfer.

Can an M12 connector be used for both power and data transmission in an industrial display?

Yes, certain M12 connectors (e.g., 5-pin or 8-pin variants) can handle both power and data signals, but the specific pin configuration and coding must align with the display’s requirements.

How do I ensure a waterproof connection when using M12 connectors in outdoor industrial displays?

Use IP67-rated M12 connectors with proper sealing, tighten them to the recommended torque, and consider additional protective enclosures for extreme weather conditions.

What is the typical lifespan of an M12 connector in an industrial environment?

M12 connectors are designed for long-term use, with a lifespan of thousands of mating cycles, but regular inspection and maintenance help prevent wear and ensure reliable performance.

Are M12 connectors compatible with standard Ethernet cables?

M12 D-coded and X-coded connectors are designed for Ethernet applications, but you may need an M12-to-RJ45 bulkhead adapter for compatibility with standard Ethernet cables.