In a market where TFT LCDs dominate due to their vibrant colors and slim profile, the alphanumeric LCDer continues to hold a place in specific applications thanks to its simplicity, durability, and low cost. Despite being a much older technology, it remains a practical choice in many industries, particularly where the display of simple alphanumeric information is needed without the complexity of graphical rendering. The mature manufacturing processes of COB and COG technologies keep production costs low, while the ability to customize displays makes alphanumeric LCDs adaptable to various needs. As technology evolves, segment code LCDs provide a path for these displays to continue being relevant, offering improved efficiency while retaining the core advantages of traditional alphanumeric LCDers. This adaptability ensures that alphanumeric LCDers remain a viable solution for many applications, even as the market continues to change.

1. The Simplest LCD Display

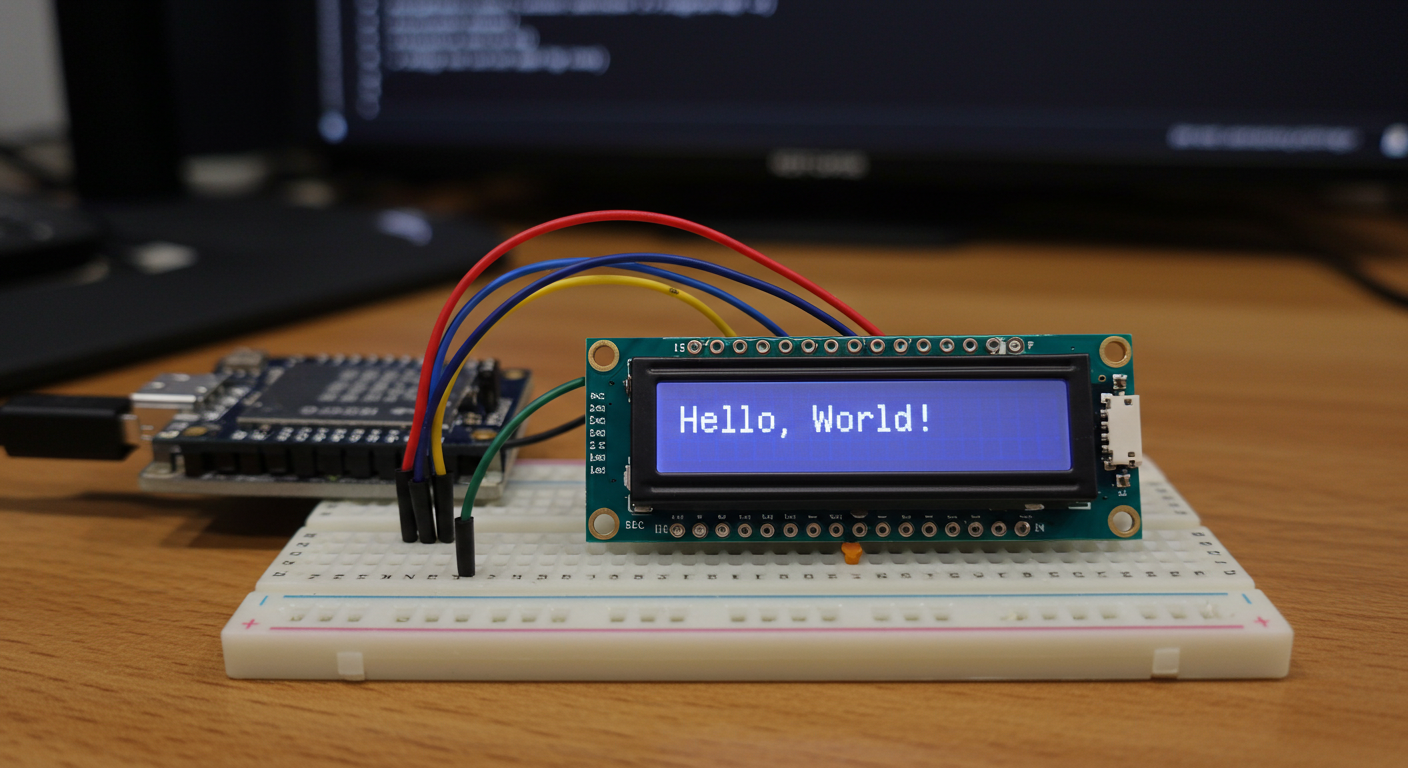

An alphanumeric LCDer, also known as a character LCD display, is designed for displaying letters and numbers. These displays come in standard configurations like 8×2, 16×2, 24×2, and 40×2 arrays, with the 16×2 alphanumeric LCD display being the most classic and widely used model. Even as TFT LCDs dominate the market, the alphanumeric LCD display still occupies a certain market share due to several key features:

Simple Development: The straightforward nature of these displays makes them easy to program and integrate into various systems.

Low Cost: They are highly affordable due to their simple structure and mature production process.

High Durability: These displays are built to last, making them ideal for use in environments where reliability is important, such as industrial control systems.

These features ensure that alphanumeric LCD displays continue to be a practical choice for certain industrial and embedded systems where simplicity, cost-efficiency, and reliability are key considerations.

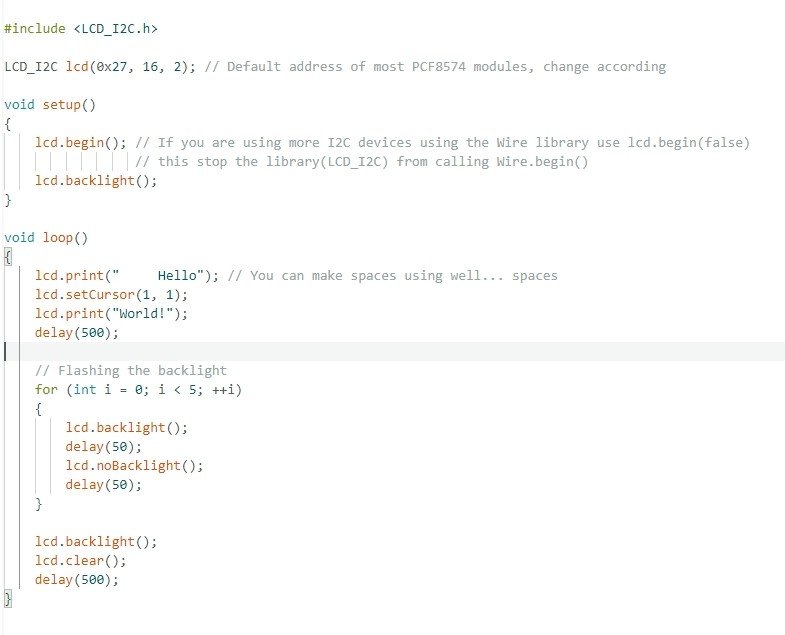

2. Development Environment

Setting up and using an alphanumeric LCDer is relatively simple. You only need to install development tools like Keil 5 or Arduino, connect the alphanumeric LCDer to the computer or microcontroller, and you can start development. This simplicity makes them ideal for beginners as well as professionals working on embedded systems. When using an alphanumeric LCDer, you have several options for displaying content:

Preset Font Sets: You can use a built-in font set to quickly display standard letters and numbers.

Custom Font Design: If needed, you can control each pixel to create custom fonts or symbols.

Because the alphanumeric LCDer is limited to displaying letters and numbers, there is less concern about complex graphical rendering, which simplifies the overall design process.

3. Alphanumeric LCD Display Manufacturers

The manufacturing processes for COB LCD (Chip on Board) and COG LCD (Chip on Glass) have reached a high level of maturity, which has significantly reduced the production costs of standard alphanumeric LCDs. This maturity has made it possible for manufacturers to produce large character LCDs at competitive prices, suitable for replacing older, bulkier displays in various applications. (how to find a good LCD module manufacturer)

-Mature Manufacturing Process: The production of COB and COG displays has reached a level where both processes are highly standardized, resulting in low manufacturing costs.

Customization Options: Many manufacturers now offer customizable large character LCDs, which can be tailored to meet specific needs. This is ideal for companies looking to implement bespoke displays into their products without a significant cost increase.

–Minimal Cost Difference: The price difference between various manufacturers is relatively small, as the components used—such as ICs, PCB circuit layouts, and pin definitions—can be easily replaced.

4. High Durability

Durability is a major strength of alphanumeric LCDers, especially when using COB packaging technology. Both COB and COG technologies are common in monochrome displays, but some critical differences make COB packaging a preferred choice in industry display:

COB vs. COG: COB LCDs are typically more durable than COG LCDs, making them well-suited for use in rugged industrial environments where displays are subject to vibrations, temperature variations, and other challenging conditions.

Industrial Applications: This durability makes COB alphanumeric LCD displays a popular choice in industrial settings, such as factory machines, control panels, and outdoor equipment where reliability is crucial.

5. Upgrade of Alphanumeric LCD Displays

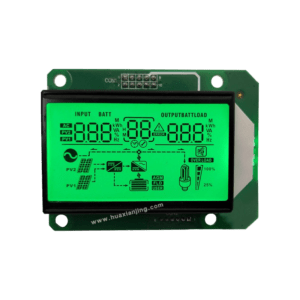

As technology evolves, even alphanumeric LCDers have undergone some upgrades, with two main directions emerging: graphic color LCDs and segment LCDs. Among these, segment LCDs offer a natural progression that maintains the core advantages of simplicity and low power consumption.

Segment LCDs: These displays are simpler than dot-matrix LCDs and consume less power, making them ideal for battery-operated devices. Unlike dot-matrix displays that require ICs to control individual pixels, segment code LCDs only need to control the activation of pre-defined segments to display specific content. This reduces the complexity of the display circuit, leading to even lower power consumption. (Differences Between Segment LCD and Dot Matrix LCD)

Transition to Segment LCDs: As a result of these efficiencies, segment code LCDs are gradually replacing dot-matrix LCDs in many applications, particularly where energy efficiency and simplicity are priorities. They have become the standard choice for monochrome displays in areas such as consumer electronics, small appliances, and industrial readouts.

Due to these advantages, segment code LCDs have gradually replaced dot-matrix LCDs and have become the mainstream choice for monochrome displays, providing a modern solution that retains the simplicity and reliability of traditional alphanumeric LCDer.