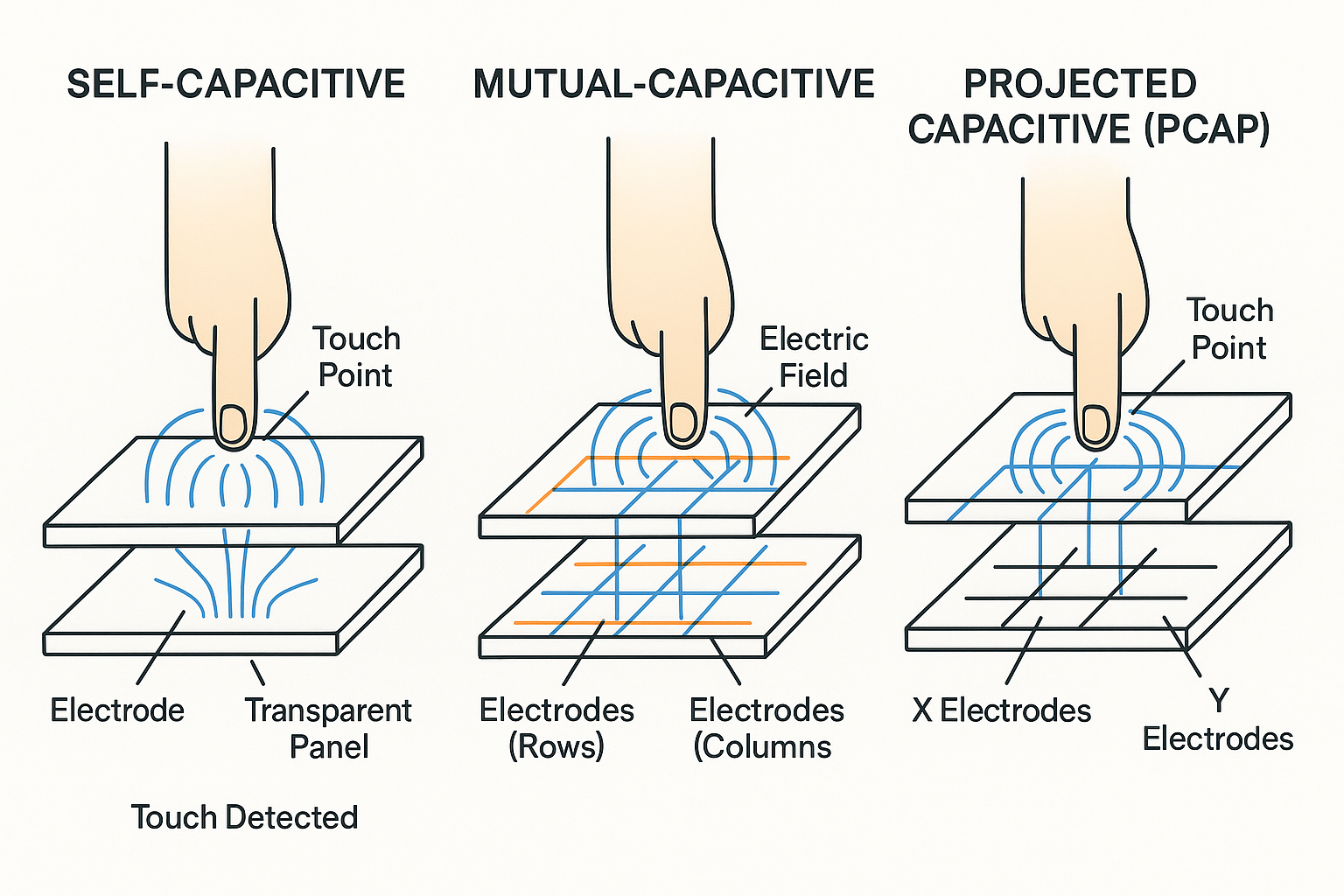

Self-capacitive touchscreens detect touch on single electrodes. Mutual-capacitive ones sense between electrode pairs for better accuracy. Projected capacitive combines these for multi-touch support.

What Is Capacitive Sensing Technology?

You might wonder how your phone knows when you touch it. Capacitive sensing makes that happen. I will explain the basics.

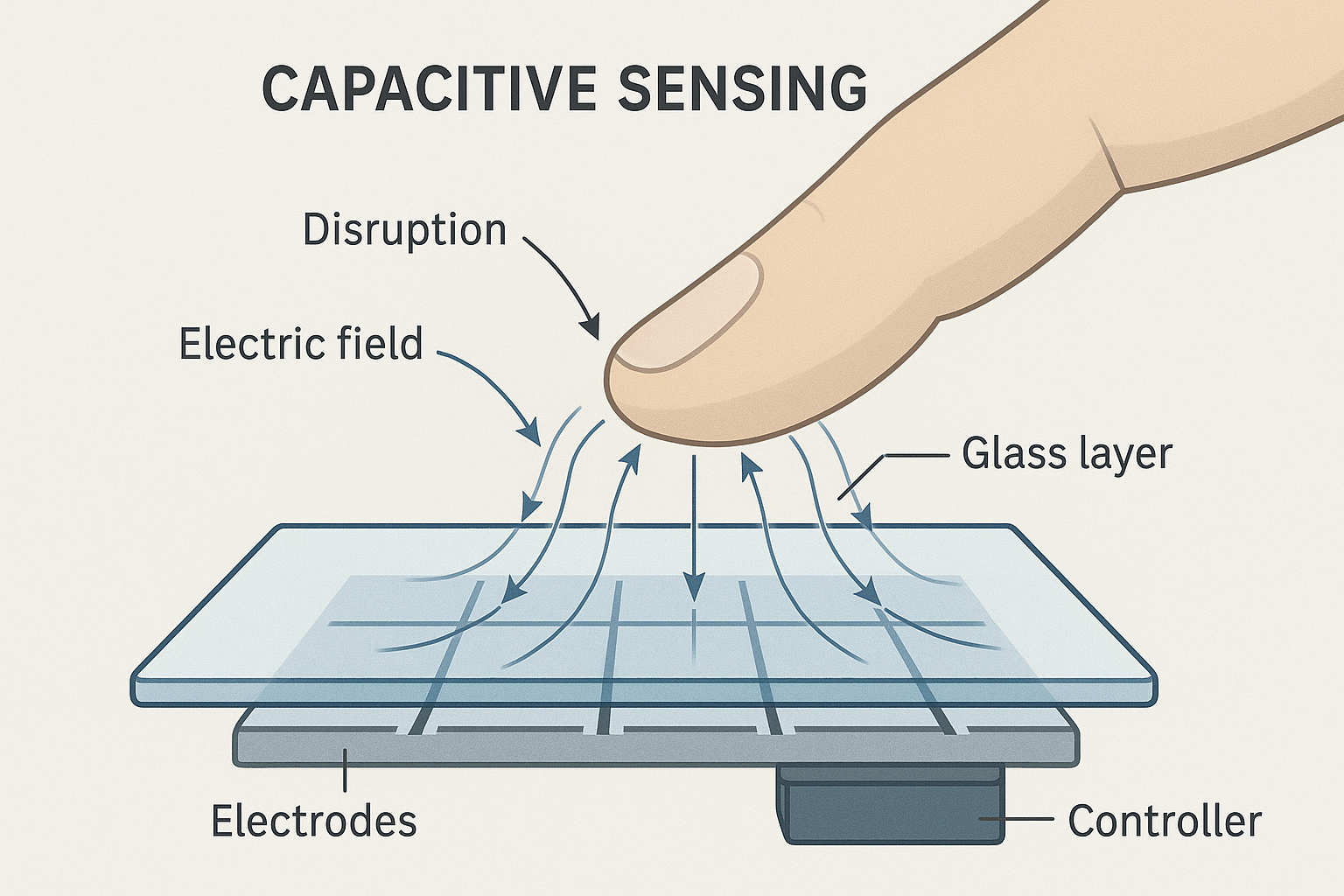

Capacitive sensing detects touch by measuring changes in electrical charge. It uses the body’s natural conductivity to alter capacitance on the screen.

Capacitive sensing technology seems complex, but its core idea is simple. It’s about measuring changes in an electrical field to detect touch.

How Does Capacitance Work in Touch Detection?

Capacitance is the ability to store charge. When you touch the screen, your finger acts as a conductor. This changes the charge field. The system spots this change and finds the touch point.

I once built a simple prototype. It used basic electrodes. The touch response was quick but limited to one point(What Is the Difference Between Capacitive and Resistive Touch Screens?).

Types of Capacitive Sensing

There are two main types: self and mutual. Self measures charge on each electrode alone. Mutual checks between electrodes.

Here is a table to show the basics:

| Type | Measurement Method | Key Feature |

|---|---|---|

| Self | Single electrode to ground | Simple, low cost |

| Mutual | Between electrode pairs | Accurate, multi-touch |

Why Choose Capacitive Over Other Technologies?

Capacitive is sensitive and durable. Resistive touch needs pressure, which wears out. Capacitive works with light touches. But it fails with gloves unless modified.

We should think about limits too. Water can trick the sensor. Engineers add filters to fix this(How is Waterproof Touch Functionality Achieved in LCD Devices?).

How Do Mutual-Capacitive Touchscreens Work?

Mutual-capacitive touchscreens power many modern devices. You use them daily without thinking. Let me break it down.

Mutual-capacitive touchscreens use a grid of electrodes. They measure capacitance changes between rows and columns to detect multiple touches accurately.

The Electrode Grid Structure

Electrodes form rows and columns. Rows send signals. Columns receive them. A touch disrupts the field at intersections.

I recall a factory test. We scanned the grid at high speed. It caught touches in milliseconds.

Signal Processing and Touch Detection

| Step | Description | Purpose |

|---|---|---|

| Pulse Send | Row electrodes get electrical pulse | Create baseline field |

| Measure | Column electrodes detect changes | Identify disruption |

| Analyze | Software calculates touch position | Provide coordinates |

Advantages and Challenges in Mutual-Capacitive Systems

This setup allows multi-touch. You can pinch to zoom. But it needs more power than self-capacitive.

One client wanted a large display. Mutual worked well for gestures. Yet, in noisy environments, we added shielding.

We must consider costs. More electrodes mean higher price. But for premium devices, it pays off.

What Defines Projected Capacitive (PCAP) Technology?

Projected capacitive sounds complex. But it is common in smartphones. I will explain what sets it apart.

Projected Capacitive (PCAP) isn’t a separate sensing method, but rather a way of building a capacitive screen. It “projects” the sensing field through a protective top layer, like glass. It supports multi-touch and works with thin gloves.

Layers in a PCAP Touchscreen

PCAP has a sensor layer under glass. It includes electrodes and a controller. The glass protects while allowing field projection.

In one project, we used ITO for electrodes. It was transparent and conductive(Why Is ITO Glass Vital for LCD Displays and Touchscreens?).

Sensitivity and Gesture Recognition

| Feature | PCAP Advantage | Example |

|---|---|---|

| Durability | Scratch-resistant glass | Smartphones |

| Sensitivity | Detects through 3mm glass | Automotive displays |

Limitations and Workarounds

PCAP is expensive to make. It also struggles with thick gloves. Engineers add amplifiers to boost signals(What Special Requirements Do Medical LCD Panels Have?).

I worked on a tablet design. PCAP allowed sleek looks. But we tested for EMI interference to ensure reliability.

Think about future uses. PCAP fits curved screens well.

How Do Self-Capacitive, Mutual-Capacitive, and Projected Capacitive Systems Compare?

Comparing these systems helps in choosing the right one. I have tested all in my work. Let’s see the differences.

Self-capacitive is simple and cheap but single-touch. Mutual-capacitive offers multi-touch accuracy. Projected capacitive adds durability and sensitivity to mutual principles.

Key Technical Differences

Self uses individual electrodes. Mutual uses pairs. PCAP is often mutual with projection.

Here is a detailed table:

| Aspect | Self-Capacitive | Mutual-Capacitive | Projected Capacitive |

|---|---|---|---|

| Touch Points | Single | Multiple | Multiple |

| Accuracy | Moderate | High | High |

| Cost | Low | Medium | High |

| Use Case | Basic buttons | Smartphones | Tablets, kiosks |

Application Scenarios

Self: Works for simple interfaces. I used it in a remote control. It was reliable but no gestures.

Mutual: shines in mid-range tablets. One project involved a game device. Multi-touch made controls smooth.

PCAP: handles harsh conditions. In an outdoor kiosk, it resisted weather.

Choosing Based on Needs

Consider budget and features. For low-cost, pick self. For advanced, go PCAP.

We should weigh power use. Mutual drains more battery.

What Are The Primary Applications and Use Cases?

The choice of technology directly depends on how the end product will be used. In my experience, matching the tech to the application is the most critical step.

Self-capacitive is for simple, single-touch devices. Mutual-capacitive and PCAP dominate consumer electronics, automotive, and industrial applications that demand multi-touch and durability.

Self-Capacitive Applications

- Home Appliances: Think of microwaves, washing machines, or refrigerators with simple touch buttons. Cost is a major driver here, and single-touch is all that’s needed.

- Industrial Control Panels: On a factory floor, a worker might just need to press a “Start” or “Stop” button. A rugged, single-touch interface is reliable and cost-effective.

- Public Kiosks: Simple information booths or ticketing machines that only require basic selections are a good fit for this technology.

Mutual-Capacitive & PCAP Applications

- Consumer Electronics: This is the biggest market. Every smartphone, tablet, and modern laptop touchpad uses mutual-capacitive PCAP for smooth, intuitive multi-touch control.

- • Automotive Infotainment: Car displays must be incredibly durable to withstand temperature changes and vibration. They also require precise multi-touch for navigating maps and media. This makes mutual-capacitive PCAP the only viable choice.

- Medical Devices: Accuracy and reliability are paramount. From patient monitors to surgical equipment interfaces, PCAP screens provide a sealed, easy-to-clean surface with the responsiveness doctors need.

- Point-of-Sale (POS) Systems: Cashiers and customers interact with these screens constantly. Durability and the ability to handle quick, repeated touches are essential.

What Developments Are Shaping Capacitive Touchscreen Technology?

This industry never stands still. The technology is constantly evolving to become more integrated, capable, and seamless for the user.

Future trends focus on making screens more flexible, embedding new sensors within the display, and creating more interactive and tactile user experiences.

Flexible and Foldable Displays

The rise of foldable phones is a huge driver of innovation. Creating a PCAP sensor that can bend hundreds of thousands of times without breaking is an incredible engineering challenge. We are seeing new materials and manufacturing processes emerge to meet this demand, allowing touch interaction to exist on curved and flexible surfaces.

In-Display Sensing

Why have a separate fingerprint sensor when you can embed it in the screen? Advanced PCAP controllers and sensor patterns can now be placed under the OLED or LCD panel to detect the ridges of a fingerprint. This allows for a larger screen-to-body ratio and a more streamlined design.

Haptic Feedback and Hover Touch

The next frontier is not just seeing your touch, but feeling it. Companies are integrating advanced haptic engines that work with the PCAP controller to provide localized vibrations. Imagine feeling a “click” on the screen exactly where your finger is pressing. Furthermore, some systems can now detect a finger hovering just above the glass, allowing for preview actions or motion gestures without ever touching the screen.

Conclusion

Understanding these capacitive technologies is key. Self-capacitive is for simple tasks, while mutual-capacitive PCAP offers the multi-touch and durable experience modern users expect.

Related Articles:

How is CAN or LIN Bus Integration Handled with LCD Modules?

How Does Signal Timing Impact LCD Image Stability?

How Does I2C for LCD Communication Work?

How Can a Serial In and Parallel Out Shift Register Simplify MCU to LCD Communication?

How Do In-Cell and On-Cell Touch Technologies Differ in Phone LCDs?

FAQ

How does temperature affect capacitive touchscreens?

Extreme temperatures can reduce sensitivity. PCAP systems with robust coatings perform better in harsh conditions.

Are capacitive touchscreens compatible with curved displays?

Yes, mutual-capacitive and PCAP support curved designs. Flexible materials like graphene enhance compatibility.

Can capacitive touchscreens handle accidental touches?

Advanced algorithms in mutual-capacitive and PCAP systems filter accidental touches. Calibration minimizes errors.

Can mutual-capacitive touchscreens work with thick gloves?

Most standard mutual-capacitive screens struggle with thick gloves, but some advanced versions support thin gloves or special glove modes.

Are capacitive touchscreens affected by humidity or water?

Basic capacitive screens can have reduced accuracy with water, but new designs and coatings help improve performance in wet environments.