Choosing between positive and negative LCD modes can be confusing when designing a display for a specific application.

Positive mode LCDs show dark content on a light background; negative mode shows light content on a dark background.

I once picked the wrong LCD mode for an outdoor device project, and users couldn’t read the screen in sunlight. After that mistake, I dug deep into how these modes work and what makes them unique. Let’s explore this together!

How do positive and negative mode LCDs work technically?

The difference comes from the direction of light transmission, liquid crystal alignment, and polarizer arrangement.

Role of polarizers in determining mode

Polarizers control how light enters and exits the LCD. In positive mode, the front polarizer allows light from the backlight (or ambient light in reflective displays) to pass through the liquid crystal layer and display dark segments on a bright background. In negative mode, the front polarizer is rotated 90°, so light is blocked unless modulated by the LCD(Why Are Circular Polarizers Used in Reflective and Transflective LCDs?).

| Mode | Polarizer Direction | Light Result |

|---|---|---|

| Positive Mode | Parallel | Light background |

| Negative Mode | Crossed | Dark background |

Liquid crystal alignment and light modulation

Liquid crystal molecules rotate light when no voltage is applied. This rotation depends on the twist angle and how the polarizers are arranged. In negative mode, higher contrast can be achieved because the light modulation is more controlled. However, it requires precise design.

Backlight dependency and implementation

Negative mode almost always requires a backlight, since ambient light is not enough. Positive mode can be reflective, transflective, or transmissive depending on the application, making it more flexible in design(What Sets Transmissive, Reflective, and Transflective LCDs Apart?).

What are the visibility characteristics of each mode in different lighting conditions?

When choosing a display mode, visibility is key.

Positive mode performs better in bright light, while negative mode excels in low light or backlit environments.

Sunlight readability comparison

In bright sunlight, negative mode LCDs win hands down. Their dark background and reflective design make text pop, while positive mode can wash out and become unreadable. I learned this the hard way on that outdoor project—positive mode just couldn’t cut it.

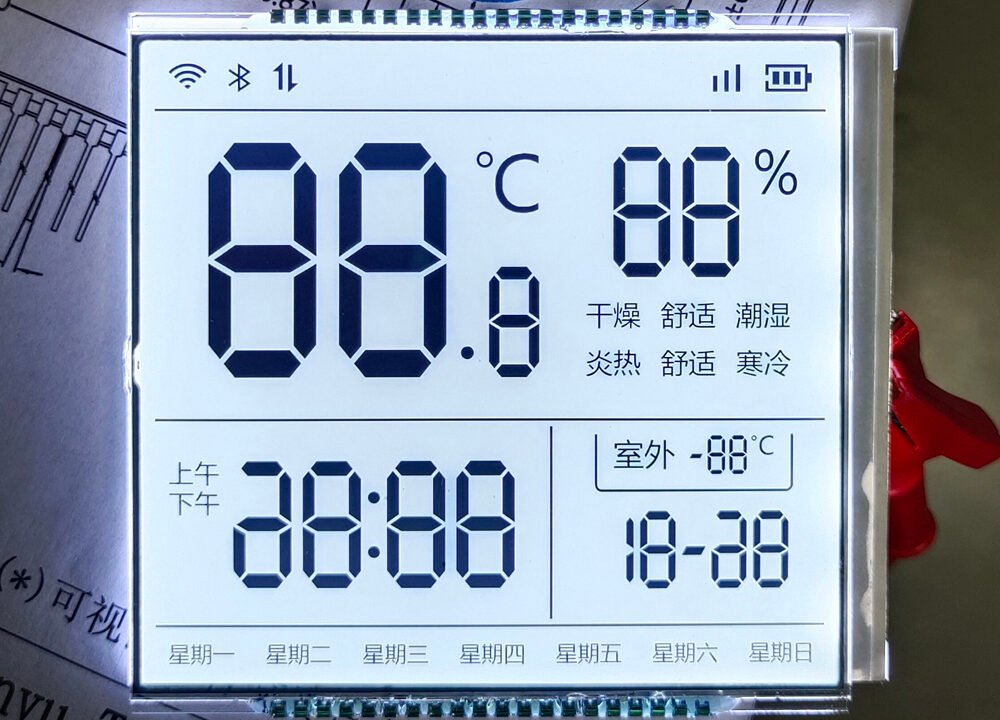

Indoor visibility and contrast

Negative mode provides better contrast indoors, especially when paired with colored backlights like blue or red. This gives a modern, stylish look often used in wearables(All That There Is To Know About the Color Alphanumeric LCD Modules).

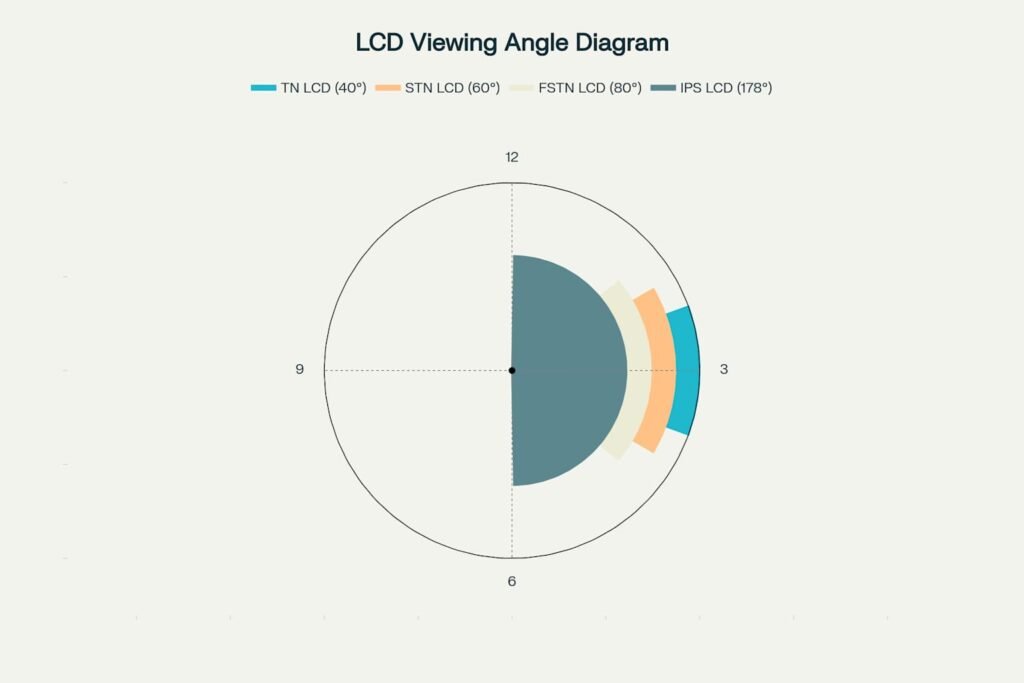

Polarizer type impact on viewing angles

Negative mode often has narrower viewing angles, especially in TN-type LCDs. FSTN or VA can help improve this. Polarizer type and alignment are major factors affecting this.

The type of polarizer affects how wide you can see the screen. TN LCDs with basic polarizers have narrow angles, while STN or FSTN with advanced polarizers offer wider views. I’ve noticed negative mode often pairs better with these upgrades for outdoor use.

What are the power consumption and cost trade-offs?

Power and cost matter in every project. Negative mode usually uses less power and costs less, but let’s break it down.

Power usage of reflective vs. transmissive modes

Negative mode’s reflective design uses ambient light, cutting power needs. Positive mode’s transmissive setup relies on a constant backlight, which eats more energy. I’ve saved battery life by switching to negative mode for portable devices.

Backlight impact on energy consumption

The backlight is the power hog in positive mode. LED backlights are more efficient than older CCFL ones, and dimming tricks can help, but it’s still a drain. Negative mode skips this entirely in some cases, which I love for low-power projects(LED Backlight Technology Analysis: CCFL, WLED, DLED, ELED, and FALED).

Cost implications for different projects

Negative mode often wins on cost. Its polarizers are cheaper, and skipping a backlight cuts production expenses. For big batches, like industrial meters, this adds up. Positive mode costs more but might be worth it for indoor clarity.

Which mode is better suited for specific applications?

The right mode depends on where your device lives. Outdoor gear loves negative mode; indoor stuff leans toward positive.

Outdoor devices (e.g., meters, handheld tools)

Negative mode is perfect for outdoor tools like meters or GPS handhelds. Sunlight makes them shine, and I’ve seen them outperform positive mode every time in the field(How Do Sunlight-Readable LCDs Maintain Contrast Outdoors?).

Indoor displays (e.g., clocks, wearables)

Positive mode rules indoors—think clocks or smartwatches. The bright background feels natural in soft light, and I’ve used it for wearables with great results.

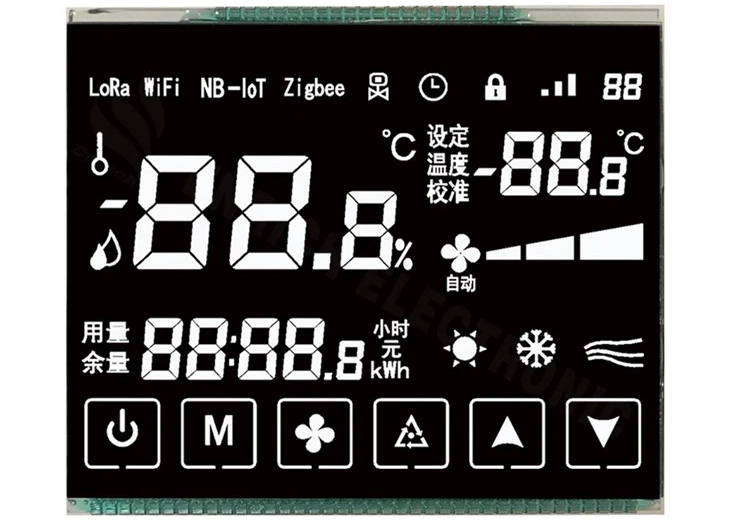

Industrial and segment LCD use cases

Industrial gear, like control panels, often picks negative mode for its durability in tough settings. Segment LCDs, with their simple digits, pair well with either, but negative mode handles varied conditions better.

How do positive and negative modes compare across different LCD types?

Not all LCDs handle modes the same way. TN, STN, FSTN, and TFT each have quirks.

TN vs. STN vs. FSTN: Which modes are supported

TN LCDs support both modes but lack wide angles. STN and FSTN lean toward negative mode for better contrast—I’ve used FSTN in outdoor displays with success(What Are the Key Differences Between TN, STN, and HTN LCD Technologies?).

TFT displays and color rendering

TFT LCDs bring full color to the table, usually in positive mode for vivid screens. Monochrome LCDs stick to black-and-white, where negative mode often shines.

Monochrome vs. full-color implementations

Monochrome LCDs favor negative mode for simplicity, while full-color TFTs go positive for richer visuals. I’ve mixed them in projects—monochrome for meters, TFT for dashboards.

What are the risks and limitations when choosing between positive and negative mode LCDs?

Picking the wrong mode has downsides. Visibility and durability can suffer.

Backlight lifespan and reliability

Positive mode’s backlight can fail—LEDs last longer than CCFL, but it’s still a weak spot. Negative mode avoids this, which I’ve found more reliable outdoors.

Environmental durability

Negative mode holds up better in heat or humidity. Positive mode needs extra protection, like waterproofing, which I’ve added to indoor designs(How is Waterproof Touch Functionality Achieved in LCD Devices?).

Risk of poor visibility in inappropriate environments

Use positive mode outside, and it fades. Use negative mode indoors, and it dims. I’ve tested both enough to know matching the environment is key.

What should you consider when customizing a segment LCD?

Custom segment LCDs need careful planning. Icons, polarizers, and production all play a role.

Segment design for icons and characters

Icons and digits must be clear and simple. I’ve designed segments that balance looks and readability—too fancy, and they confuse users(How to Design Your Own Segment LCD?).

Polarizer choice for custom applications

Pick transmissive polarizers for positive mode or reflective for negative. I match them to the project’s lighting needs every time.

Custom LCD panel production considerations

Prototypes take about 7 days, and mass production hits 30. I factor in cost and time when planning custom runs.

How do positive/negative mode LCDs compare to modern alternatives?

LCDs aren’t the only game in town. OLED and TFT offer new options.

OLED vs. negative mode LCDs

OLED’s self-lit pixels beat negative mode in contrast and power use. I’ve swapped LCDs for OLED in high-end designs—it’s a step up.

TFT LCDs and their benefits over monochrome types

TFT brings color and resolution monochrome can’t touch. I’ve used it for vibrant displays where monochrome felt dated.

Conclusion

Choosing between positive and negative mode LCDs comes down to your project. Positive mode rocks indoors; negative mode owns the outdoors. Factor in power, cost, and environment, and you’ll pick a winner every time.

Related Articles:

What Is the Difference Between Capacitive and Resistive Touch Screens?

How to Implement UART for Monochrome LCD Communication?

What Are the Differences Between SPI and I2C for LCD Modules?

What Special Requirements Do Medical LCD Panels Have?

How Can You Program a Graphic LCD Module to Show Custom Graphics?

FAQ

Why does my negative LCD look blurry from an angle?

Negative mode displays, especially TN, often have narrow viewing angles that cause blurriness when viewed off-center.

Will a positive mode LCD work well at night?

Yes, if it’s a transmissive or transflective type with a backlight. Pure reflective types are hard to see in the dark.

Is negative mode better for color displays?

Yes, most color TFTs use negative mode for better contrast and deeper blacks.

Do negative mode LCDs always consume more power?

Usually yes, because their backlight is constantly on to maintain visibility.

What if my application needs both indoor and outdoor visibility?

Transflective negative mode LCDs balance indoor and outdoor visibility. Contact us for tailored solutions.