I get this question almost daily from customers who want to understand whether they need an industrial or commercial LCD display for their project. It’s a crucial decision that can impact both performance and budget.

Industrial LCD displays feature enhanced durability, wider temperature ranges, higher brightness levels, and longer lifespans compared to commercial displays, making them essential for manufacturing, transportation, and harsh environment applications.

After 13 years in the LCD industry, I’ve witnessed firsthand how choosing the wrong display type can lead to costly failures, production downtime, and disappointed customers. Let me share what I’ve learned about these two distinct display categories.

Environmental Durability

One of the most significant differences between industrial and commercial LCD displays lies in their environmental durability. This difference often determines project success or failure in demanding applications.

Industrial LCD displays are engineered to withstand extreme environmental conditions that would destroy commercial displays, including temperature fluctuations, dust, moisture, and vibrations.

Wide Temperature Range

The temperature range capability represents perhaps the most critical difference between these display types. Commercial displays typically operate within a narrow temperature range of 0°C to 50°C (32°F to 122°F), while industrial displays can function in much broader ranges(What Temperature Range Can LCD Modules Safely Operate In?).

Industrial LCD displays are available in three temperature categories:

- Standard temperature: -20°C to 70°C (-4°F to 158°F)

- Wide temperature: -30°C to 80°C (-22°F to 176°F)

- Super wide temperature: -40°C to 85°C (-40°F to 185°F)

This enhanced temperature tolerance is achieved through specialized liquid crystal materials and advanced thermal management systems. The liquid crystal formulations in industrial displays maintain their molecular alignment across extreme temperature variations, ensuring consistent performance.

When temperatures drop below operational limits, standard LCD displays experience slowed response times, increased power consumption, and reduced contrast. At extremely low temperatures, the liquid crystal can freeze, causing complete display failure. Conversely, high temperatures can cause the liquid crystal to become disoriented, leading to dim or completely dark screens.

Resistance to Dust, Water, and Vibration

Industrial LCD displays feature robust IP (Ingress Protection) ratings that commercial displays simply cannot match. These ratings indicate the level of protection against solids and liquids(How Are LCDs Tested for Resilience to Sand, Dust, and Particulate Ingress?).

| IP Rating | Dust Protection | Water Protection | Typical Applications |

|---|---|---|---|

| IP54 | Limited dust protection | Protected against splashing water | Basic industrial environments |

| IP65 | Complete dust protection | Protected against water jets | Manufacturing facilities |

| IP66 | Complete dust protection | Protected against powerful water jets | Outdoor applications |

| IP67 | Complete dust protection | Protected against temporary immersion | Marine environments |

Industrial displays achieve these high IP ratings through sealed enclosures, gaskets, and specialized coatings that prevent ingress of contaminants. This protection is essential in environments where dust, moisture, or cleaning chemicals are present.

Vibration resistance is another critical factor. Industrial displays incorporate reinforced internal components, shock-absorbing mechanisms, and robust mounting systems to withstand constant vibration from machinery and equipment. This durability extends their operational lifespan significantly compared to commercial displays.

Rugged Design Features

The physical construction of industrial LCD displays differs dramatically from commercial units. Industrial displays utilize:

- Metal enclosures: Constructed from aluminum or stainless steel instead of plastic, providing superior impact resistance and heat dissipation

- Reinforced glass: Tempered or chemically strengthened glass that can withstand physical impacts and thermal stress

- Sealed connections: All cable connections are sealed to prevent moisture ingress and maintain signal integrity

- Corrosion-resistant coatings: Special treatments protect against chemical exposure and environmental degradation

These rugged design features ensure reliable operation in harsh industrial environments where commercial displays would fail within weeks or months.

Display Performance

Performance characteristics represent another fundamental difference between industrial and commercial LCD displays, with industrial units optimized for visibility and reliability rather than entertainment value.

Industrial LCD displays prioritize visibility, brightness, and readability over color accuracy and aesthetic appeal, with brightness levels often exceeding 1000 nits compared to 250-350 nits for commercial displays.

Brightness and Contrast

Industrial LCD displays typically provide significantly higher brightness levels to ensure visibility in challenging lighting conditions. While commercial displays usually offer 250-350 nits, industrial displays can provide 500-1500 nits or more(Why Do High-Lumen Lights Fail in Outdoor Environments?).

| Display Type | Brightness Range | Typical Applications |

|---|---|---|

| Commercial LCD | 250-350 nits | Indoor offices, homes |

| Standard Industrial | 500-1000 nits | Manufacturing floors, control rooms |

| High Brightness Industrial | 1000-1500 nits | Outdoor applications, direct sunlight |

This enhanced brightness is achieved through high-power LED backlighting systems and optimized optical designs. The increased brightness ensures that critical information remains visible even in bright ambient lighting conditions or direct sunlight exposure.

Contrast ratios in industrial displays are optimized for readability rather than entertainment. While commercial displays may prioritize deep blacks for movie viewing, industrial displays focus on maintaining consistent contrast across various viewing angles and lighting conditions.

Viewing Angles

Industrial LCD displays often utilize IPS (In-Plane Switching) technology to provide wide viewing angles, ensuring that multiple operators can view the display clearly from different positions. This is particularly important in control rooms and manufacturing environments where multiple personnel need to monitor the same display(How Can You Improve LCD Viewing Angles?).

The viewing angle specifications for industrial displays typically include:

- Horizontal viewing angle: 170-178 degrees

- Vertical viewing angle: 170-178 degrees

- Contrast ratio maintenance: >80% across the viewing angle range

These wide viewing angles are achieved through advanced liquid crystal technologies and specialized polarizer films that maintain image quality regardless of the viewing position.

Sunlight Readability Enhancements

Industrial displays incorporate specific technologies to enhance readability in bright outdoor conditions:

- Anti-reflective coatings: Reduce glare and reflections from ambient light sources

- Transflective technology: Allows the display to use both backlight and ambient light for enhanced visibility

- Optical bonding: Eliminates air gaps between the LCD panel and cover glass, reducing reflections and improving contrast

- Circular polarizers: Minimize reflections from curved surfaces and provide better sunlight readability

These enhancements ensure that critical information remains visible even in challenging outdoor environments where commercial displays would be completely unreadable(How Do Sunlight-Readable LCDs Maintain Contrast Outdoors?).

Reliability and Lifespan

The reliability and lifespan differences between industrial and commercial LCD displays represent one of the most significant factors in total cost of ownership calculations.

Industrial LCD displays are designed for continuous 24/7 operation with lifespans of 50,000-100,000 hours, while commercial displays typically last 30,000-50,000 hours with intermittent use patterns.

Continuous Operation

Industrial LCD displays are engineered for continuous operation, often running 24 hours a day, 7 days a week for years without failure. This capability is achieved through several design considerations:

- Industrial-grade components: Higher quality capacitors, resistors, and integrated circuits that can withstand continuous operation

- Enhanced thermal management: Advanced cooling systems and heat dissipation mechanisms prevent overheating during continuous use

- Robust power supplies: Industrial-grade power management systems that provide stable operation under varying load conditions

Commercial displays, conversely, are designed for intermittent use patterns of 5-9 hours per day. Extended continuous operation causes rapid degradation of commercial display components, leading to reduced brightness, color shifts, and eventual failure.

Extended Lifespan

The Mean Time Between Failures (MTBF) for industrial LCD displays significantly exceeds that of commercial units(What Is the Typical MTBF for Commercial LCD Modules?):

| Display Type | MTBF (Hours) | Expected Lifespan | Typical Usage Pattern |

|---|---|---|---|

| Commercial LCD | 30,000-50,000 | 3.5-7 years | Intermittent use |

| Industrial LCD | 50,000-100,000 | 5-10 years | Continuous operation |

This extended lifespan is achieved through superior component selection, rigorous testing procedures, and design optimization for long-term reliability. Industrial displays undergo extensive aging tests and component screening to ensure only the highest quality parts are used in production.

The longer lifespan of industrial displays translates to reduced replacement costs, lower maintenance requirements, and improved system uptime. In critical applications, this reliability difference can mean the difference between profitable operations and costly downtime.

Certifications and Standards

Industrial LCD displays must meet stringent certification requirements that commercial displays typically don’t need to address, ensuring safety and reliability in demanding applications.

Industrial LCD displays require compliance with multiple industry-specific certifications including IP ratings, EMC standards, and safety regulations that commercial displays are not required to meet.

Industry-Specific Certifications

Industrial LCD displays must comply with various industry-specific standards depending on their intended application:

| Certification | Application | Requirements |

|---|---|---|

| UL (Underwriters Laboratories) | General industrial use | Electrical safety and fire resistance |

| CE (Conformité Européenne) | European market | Safety, health, and environmental protection |

| FCC (Federal Communications Commission) | North American market | Electromagnetic compatibility |

| IEC 60601 | Medical applications | Medical electrical equipment safety |

| ATEX | Explosive atmospheres | Intrinsically safe design for hazardous locations |

These certifications require extensive testing and documentation to ensure the displays meet specific performance and safety criteria.

Certification Upgrades

Industrial display manufacturers often provide certification upgrade paths to meet evolving regulatory requirements. This includes:

- Environmental compliance: RoHS compliance for hazardous substance restrictions

- Electromagnetic compatibility: EMC testing to ensure the display doesn’t interfere with other equipment

- Functional safety: ISO 26262 for automotive applications or IEC 61508 for general industrial safety

- Quality management: ISO 9001 certification for manufacturing processes

These ongoing certification requirements ensure that industrial displays continue to meet the highest standards for safety and reliability throughout their operational life.

Customization and Integration

The customization capabilities of industrial LCD displays far exceed those of commercial units, allowing for tailored solutions that meet specific application requirements.

Industrial LCD displays offer extensive customization options including custom interfaces, mounting solutions, and integration capabilities that commercial displays cannot provide.

Tailored Configurations

Industrial LCD manufacturers provide comprehensive customization services:

- Custom mechanical designs: Bezels, enclosures, and mounting systems tailored to specific applications

- Interface modifications: Custom connector types, cable lengths, and signal processing

- Environmental adaptations: Special coatings, gaskets, and protection levels for specific environments

- Brightness optimization: Custom backlighting solutions for specific visibility requirements

These customization options ensure that the display integrates seamlessly into existing systems and meets exact operational requirements.

System Compatibility

Industrial displays are designed to integrate with various industrial systems and protocols:

- Industrial communication protocols: Support for PROFIBUS, PROFINET, EtherNet/IP, and other industrial networks

- Legacy system compatibility: Interfaces for older industrial equipment and control systems

- Multiple input formats: Support for various video formats and resolutions to match existing systems

- Embedded computing: Options for integrated processing units and control systems

This compatibility ensures that industrial displays can be integrated into complex industrial automation systems without requiring extensive system modifications.

Which Industries Require Industrial LCD Displays?

Understanding which industries require industrial LCD displays helps clarify when these specialized displays are essential versus optional.

Industrial LCD displays are essential in manufacturing, transportation, healthcare, energy, and defense applications where reliability, durability, and performance are critical to operations.

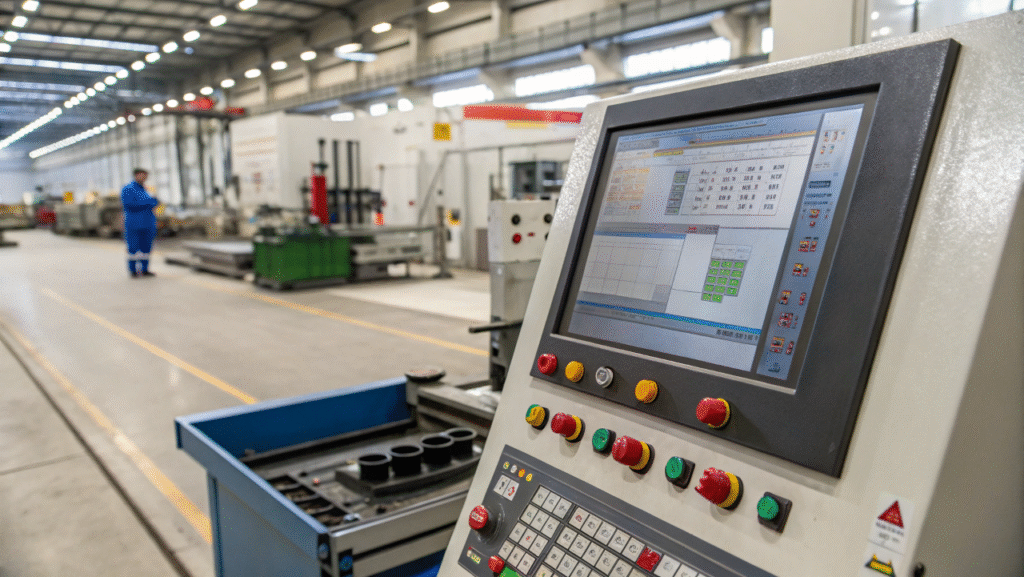

Manufacturing and Industrial Automation

Manufacturing environments present some of the most demanding conditions for LCD displays:

- Factory floor monitoring: Displays must withstand dust, vibration, temperature fluctuations, and chemical exposure

- Process control: Real-time monitoring of production parameters requires displays that never fail during critical operations

- Quality inspection: High-resolution displays for detailed component inspection and defect detection

- Equipment interfaces: Machine control panels that operators interact with continuously throughout shifts

In these applications, display failure can result in production line shutdowns costing thousands of dollars per hour, making the reliability of industrial displays essential(How Are Embedded LCDs Used in Human-Machine Interfaces (HMIs) for Industrial Control Systems?).

Transportation and Logistics

Transportation applications demand displays that can withstand constant vibration, temperature extremes, and outdoor exposure:

- Vehicle displays: Dashboard instruments, navigation systems, and passenger information displays

- Railway systems: Platform displays, train control systems, and passenger information systems

- Maritime applications: Bridge displays, navigation systems, and communication interfaces that must withstand salt water exposure

- Aviation: Cockpit displays, passenger information systems, and ground support equipment

These applications require displays that maintain readability and functionality regardless of environmental conditions or operational stress().

Medical and Healthcare Applications

Healthcare environments require displays that meet stringent safety and hygiene standards:

- Medical imaging: High-resolution displays for diagnostic imaging that require precise color accuracy and brightness

- Patient monitoring: Displays that provide continuous vital sign monitoring without failure

- Surgical equipment: Displays integrated into surgical systems that must function reliably during critical procedures

- Laboratory equipment: Displays for analytical instruments that require precise readings and data visualization

Medical applications often require additional certifications such as IEC 60601 for medical electrical equipment safety(What Special Requirements Do Medical LCD Panels Have?).

Military and Defense

Military applications demand the highest levels of reliability and environmental protection:

- Rugged displays: Units that can withstand extreme temperatures, shock, vibration, and electromagnetic interference

- Night vision compatibility: Displays with specialized backlighting that doesn’t interfere with night vision equipment

- TEMPEST compliance: Displays that prevent electromagnetic emissions that could compromise security

- Battlefield durability: Displays that continue functioning after physical damage or extreme environmental exposure

These applications require displays that meet military specifications (MIL-STD) for environmental testing and reliability.

What Touch Screen Technologies Work Best in Industrial Applications?

Touch screen technology selection significantly impacts the usability and reliability of industrial LCD displays, with different technologies offering distinct advantages.

Resistive, projected capacitive, and infrared touch technologies each offer unique advantages for industrial applications, with selection depending on environmental conditions and operational requirements(What Is the Difference Between Capacitive and Resistive Touch Screens?).

Resistive Touch Screens

Resistive touch screens remain popular in industrial applications due to their versatility and reliability:

Advantages:

- Universal activation: Can be activated by any object, including gloved hands, styluses, or tools

- Cost-effective: Lower cost compared to other touch technologies

- Environmental resistance: Not affected by dust, water, or electromagnetic interference

- High precision: Excellent accuracy for detailed input requirements

Disadvantages:

- Limited multitouch: Cannot support complex multitouch gestures

- Reduced transparency: Lower light transmission affects display brightness

- Durability concerns: Surface can be damaged by sharp objects

Resistive touch screens are ideal for industrial applications where operators wear gloves or use tools to interact with the display.

Projected Capacitive (PCAP) Touch Screens

PCAP touch screens offer superior performance and durability in many industrial applications(Self Mutual Projected Capacitive Touchscreen: What Is It?):

Advantages:

- Multitouch support: Can detect multiple simultaneous touch points

- High transparency: Excellent light transmission for bright, clear displays

- Durability: Chemically strengthened glass surface resists scratches and damage

- Sensitivity: Responds to light touch, improving user experience

Disadvantages:

- Glove compatibility: Limited functionality with thick gloves

- Cost: Higher cost than resistive technology

- Size limitations: Becomes expensive for very large displays

PCAP touch screens are preferred in clean industrial environments where operators don’t need to wear heavy gloves.

Infrared Touch Technology

Infrared touch technology offers unique advantages for large industrial displays:

Advantages:

- Large size capability: Can be implemented on very large displays cost-effectively

- Multitouch support: Supports up to 40 simultaneous touch points

- No surface contact: Touch detection occurs without physical contact with the screen

- Durability: No physical touch surface to wear out

Disadvantages:

- False activation: Can be triggered by debris, insects, or ambient light

- Environmental sensitivity: Affected by dust, dirt, or moisture on the bezel

- Bezel requirements: Requires visible bezels for infrared emitters and sensors

Infrared touch is ideal for large industrial displays where multitouch capability is required and environmental conditions are controlled.

Additional User Considerations

Beyond the core technical differences, several additional factors significantly impact the selection and deployment of industrial LCD displays.

Energy efficiency, connectivity options, serviceability, EMI protection, and vendor support are critical factors that determine the long-term success of industrial LCD deployments.

Energy Efficiency

Energy efficiency has become increasingly important in industrial LCD applications, both for cost savings and environmental compliance:

- Power consumption: Industrial displays consume 25% less power than equivalent CRT displays

- LED backlighting: Modern industrial displays use efficient LED backlighting that reduces power consumption by 30-50% compared to CCFL backlighting

- Adaptive brightness: Automatic brightness adjustment based on ambient light conditions reduces power consumption

- Power management: Advanced power management systems optimize energy use during idle periods

Energy-efficient displays reduce operational costs and support corporate sustainability initiatives while maintaining performance requirements(How can I reduce LCD power consumption in embedded systems?).

Connectivity and Controller Compatibility

Industrial LCD displays must integrate with various industrial systems and protocols:

- Industrial interfaces: Support for RS-232, RS-485, CAN bus, and other industrial communication protocols

- Video inputs: Multiple input formats including VGA, DVI, HDMI, and DisplayPort

- Network connectivity: Ethernet connectivity for remote monitoring and control

- Controller compatibility: Compatibility with industrial PCs, PLCs, and embedded systems

Proper connectivity ensures seamless integration with existing industrial automation systems without requiring extensive modifications.

Repair and Serviceability

The serviceability of industrial LCD displays significantly impacts total cost of ownership:

- Modular design: Components can be replaced individually without replacing the entire display

- Field service: On-site repair capabilities reduce downtime

- Spare parts availability: Long-term availability of replacement parts and components

- Technical support: Dedicated technical support teams with industrial application expertise

Good serviceability reduces maintenance costs and ensures maximum uptime for critical industrial applications.

EMI Shielding and EMC Robustness

Electromagnetic interference (EMI) protection is crucial in industrial environments with high electrical noise:

- EMI shielding: Conductive coatings and mesh screens prevent electromagnetic interference

- Shielding effectiveness: Typical shielding effectiveness of 40-60 dB at frequencies up to 1000 MHz

- Grounding systems: Proper grounding prevents EMI issues and ensures signal integrity

- Compliance testing: EMC testing ensures displays don’t interfere with other equipment

EMI protection prevents display malfunction and ensures reliable operation in electrically noisy industrial environments(What EMI/EMC Rules Must Automotive LCD Displays Follow?).

Environmental and Disposal Compliance

Environmental regulations increasingly affect industrial LCD selection and disposal:

- RoHS compliance: Restriction of hazardous substances in electronic equipment

- REACH compliance: Registration and restriction of chemical substances

- Recycling programs: Proper disposal and recycling of end-of-life displays

- Energy efficiency standards: Compliance with energy efficiency regulations

Proper environmental compliance ensures regulatory compliance and supports corporate sustainability goals.

Vendor Credibility and Support

The selection of a reliable vendor is critical for long-term success:

- Industry experience: Vendors with proven experience in industrial applications

- Technical expertise: Engineering support for custom solutions and integration

- Quality certifications: ISO 9001 and other quality management certifications

- Long-term support: Commitment to long-term product availability and support

A reliable vendor partnership ensures ongoing support, timely delivery, and technical assistance throughout the product lifecycle.

Conclusion

The differences between industrial and commercial LCD displays extend far beyond simple cost considerations. Industrial displays provide superior environmental durability, enhanced performance characteristics, longer lifespans, and specialized features that make them essential for demanding applications. While commercial displays suffice for office and consumer applications, industrial environments require the reliability, durability, and performance that only industrial-grade displays can provide.

FAQ

What are the maintenance requirements for industrial LCD displays?

Industrial LCDs require simple cleaning and periodic checks, but they are designed to minimize downtime and last longer between service intervals.

How much does it cost to replace an industrial LCD compared to a commercial one?

Industrial LCD replacement costs are typically 2-3 times higher than commercial displays, depending on size and specifications. However, the extended lifespan and reduced maintenance needs often result in lower total cost of ownership over time.

What happens if my industrial LCD fails outside the warranty period?

Most industrial LCD suppliers offer repair services and maintain spare parts for 5-7 years after product discontinuation. Repair costs typically for most issues, which is significantly less expensive than complete replacement and much faster than sourcing a new display.

Can I use a cheaper commercial display if I add protective housing?

While protective housing can help, it cannot address the fundamental differences in internal components, temperature ranges, and component quality that make industrial displays reliable. Commercial displays will still fail prematurely in harsh environments, leading to higher long-term costs and downtime.

Are industrial LCD warranties different from commercial display warranties?

Industrial LCD warranties are typically more comprehensive, covering 24/7 operation and harsh environmental conditions that would void commercial warranties. However, they often exclude physical damage, liquid exposure, and improper installation, similar to commercial warranties.