LCD polarizer film is everywhere, but many people have no idea what it does. Let’s clear up the confusion quickly.

LCD polarizer film is a plastic optical layer used in LCDs to control and filter light. It creates contrast, brightness, and displays images by blocking and allowing light waves based on their direction.

When I started working with LCD modules, I wondered why screens looked white when taken apart. It all came down to the polarizer film. If you’re curious too, keep reading.

What Does a Polarizer Do in LCDs?

The function of a polarizer is often misunderstood. Here’s the real story.

A polarizer in an LCD only allows light vibrating in one direction to pass through, creating the foundation for images and controlling glare and brightness.

How does a polarizer work?

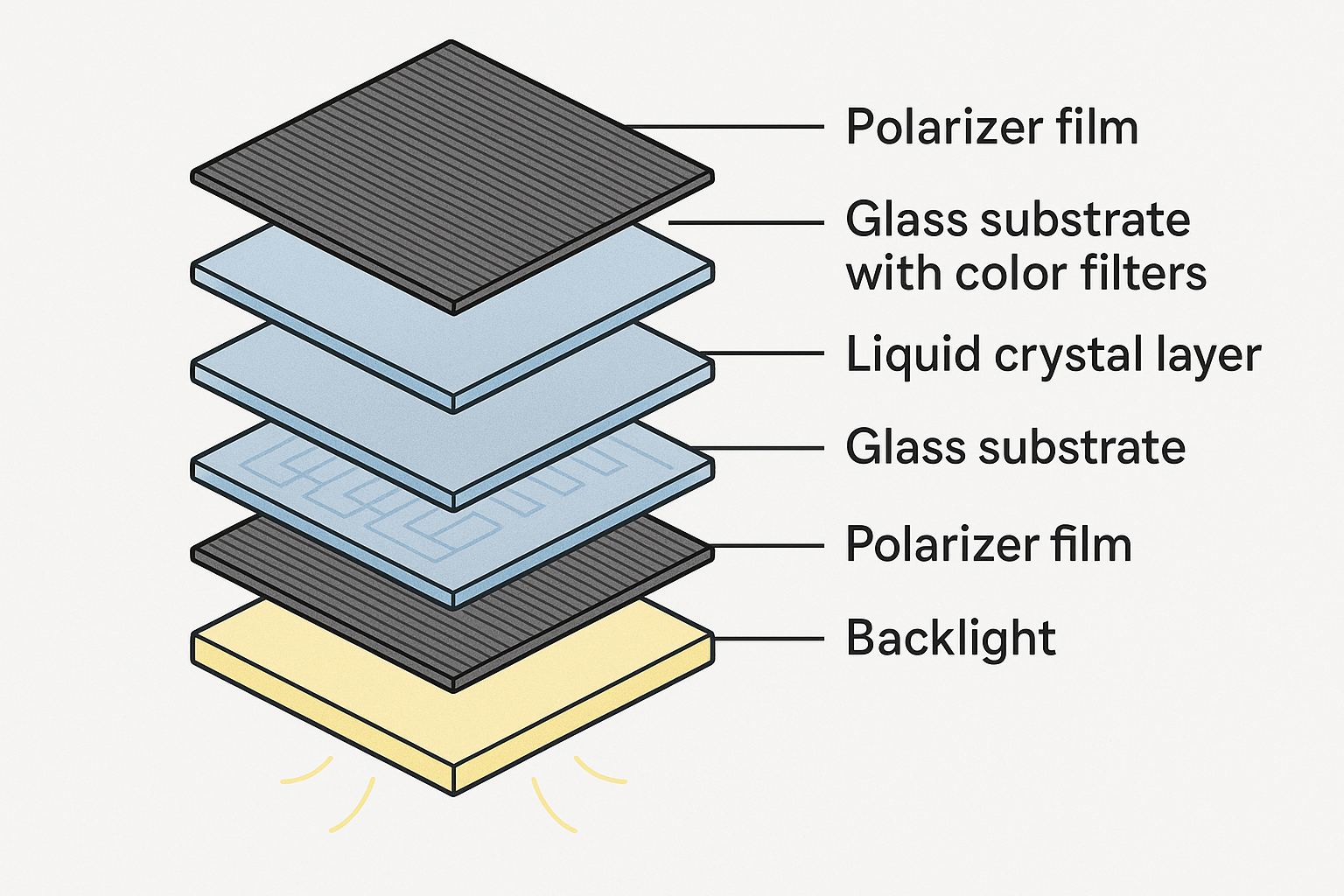

A polarizer is a type of filter. It blocks light waves that don’t vibrate in the chosen direction. When light from the backlight passes through the first polarizer, it emerges polarized. The liquid crystals inside the display can twist this light’s direction. The second polarizer, placed at 90 degrees to the first, then decides how much light to let through based on the liquid crystal’s twist. This process turns invisible voltage changes into visible images. Without the polarizer, the screen would not show anything but a white glow.

What represents LCD on a screen?

LCD stands for Liquid Crystal Display. The polarizer is just one critical layer among others like the glass substrate and liquid crystal material. Together, they bring images to life.

What Are LCD Polarizer Films Made Of?

Not all plastics are created equal. So what’s inside these films?

LCD polarizer film is mainly made from plastic—typically stretched polyvinyl alcohol (PVA) for the polarizing layer, sandwiched between layers of protective triacetate cellulose (TAC).

The main component, polyvinyl alcohol, aligns during the manufacturing process to filter light. Manufacturers dye it with iodine or other chemicals to absorb certain light waves. The plastic layer is very thin but strong, and the outer TAC layers provide scratch resistance and structural support. Modern designs can add adhesive layers, anti-glare coatings, or even UV protection for outdoor use(Optical Bonding vs. Air Bonding: Which is Better for Your LCD Module?).

| Layer | Material | Function |

|---|---|---|

| Core | Polyvinyl Alcohol (PVA) | Polarizing |

| Outer Coating | Triacetate Cellulose | Protection, clarity |

| Adhesive | Acrylic, optically clear | Bonding to glass |

| Extras | Hard coat, anti-glare | Durability, visibility |

What Varieties of Polarizer Film Exist?

You may have seen different screen types. Polarizer films are not all the same.

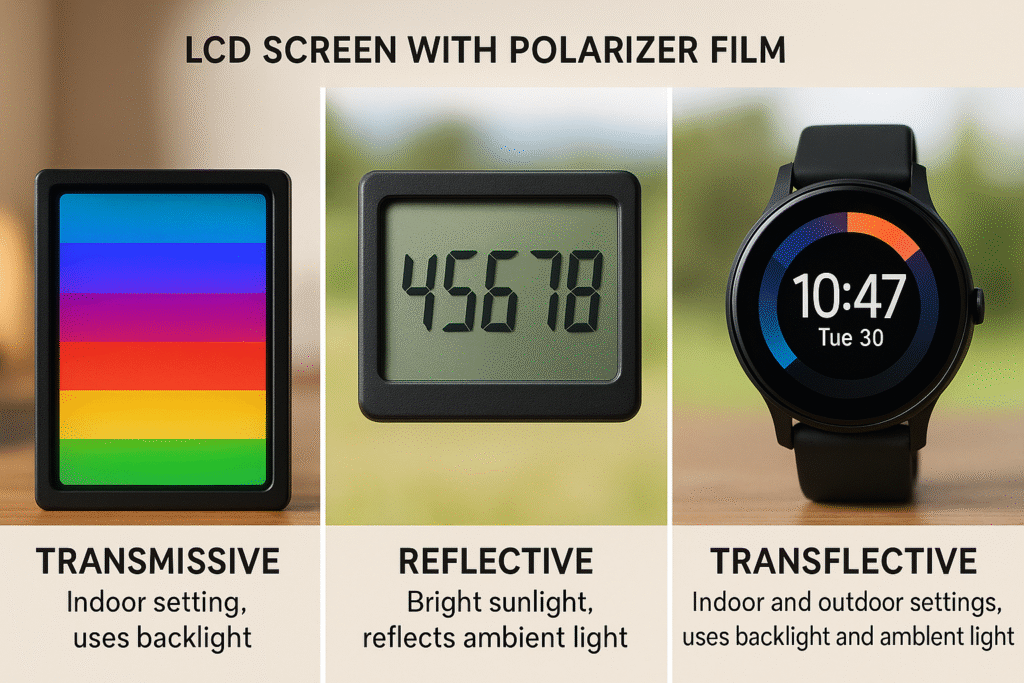

There are three main types: transmissive, reflective, and transflective polarizer films. Each handles light differently for various applications(What Sets Transmissive, Reflective, and Transflective LCDs Apart?).

Transmissive Polarizer Film

Transmissive types let backlight pass directly through. Most consumer devices use this type because it supports vibrant colors and high brightness in indoor lighting.

Reflective Polarizer Film

Reflective films bounce ambient light back toward the viewer. This makes them perfect for displays used outdoors or in strong light, where backlight alone isn’t enough.

Transflective Polarizer Film

| Type | Backlight Use | Ambient Light Use | Example Application |

|---|---|---|---|

| Transmissive | Yes | Low | TVs, monitors |

| Reflective | No | High | Calculators, watches |

| Transflective | Yes | High | Outdoor devices, meters |

Benefits of LCD Polarizer Films

Why do we need polarizers at all? Their value is bigger than you think.

LCD polarizer films increase display contrast, reduce glare, and enable clear images. Without them, LCD screens would show only a white glow.

Polarizers give LCDs their signature crispness. When I work with OEM clients, they often ask why some displays look washed out. The answer is usually cheap or damaged polarizer film. High-quality polarizers ensure images pop, even in bright sunlight. They cut glare, improve viewing angles, and allow thinner displays by boosting efficiency. Repairing a polarizer can fix what looks like a dead display.

What does a polarizer do about glare?

The polarizing layer reduces glare by blocking light waves that scatter randomly. This makes screens easier to see, even under direct lighting. That’s why polarized monitor screens are popular in offices and vehicles.

Broader Applications of Polarized Films

Polarizer film is not just for LCDs. Its use goes much further.

Polarized film is used in photography, sunglasses, scientific equipment, and industrial displays—wherever controlling light direction and reducing glare are needed(How Do Dual-Layer LCDs Enhance Contrast Ratios?).

Photography

Photographers use polarizing filters to reduce reflections and boost color contrast in outdoor shots. The same principle as LCD polarizer film applies.

Sunglasses

Polarized sunglasses use similar plastic films to block glare from roads or water, making driving and fishing safer.

Industrial and Scientific Use

Polarizers help in microscopes and lasers, revealing details hidden by glare or scattered light. In factories, they inspect materials for defects by controlling how light interacts with surfaces.

How Do LCDs Work with Polarizers?

The process inside an LCD is invisible to the naked eye. But polarizers are the secret ingredient.

LCDs work by sandwiching liquid crystals between two polarizers. Changing the crystals’ alignment with voltage controls how much light passes, forming the display image.

Step-by-Step Working Principle

- The backlight shines unpolarized light.

- The first polarizer film lets through only light in one direction.

- The liquid crystal layer rotates this polarized light when voltage is applied.

- The second polarizer, set perpendicular to the first, allows some or all of this light through, depending on the crystals’ twist.

- Varying the voltage at each pixel creates the contrast and images you see.

| Step | Component | What Happens |

|---|---|---|

| 1 | Backlight | Produces unpolarized light |

| 2 | First Polarizer | Polarizes light in one direction |

| 3 | Liquid Crystals | Rotate polarization based on voltage |

| 4 | Second Polarizer | Selectively passes twisted light |

| 5 | Screen Image | Light/dark pixels form the image |

What does LCD stand for in math?

In mathematics, LCD can mean “least common denominator,” which is unrelated to display technology. In electronics, LCD always refers to “Liquid Crystal Display.”

Conclusion

LCD polarizer films are indispensable optical components that enable image display by precisely controlling light polarization. They are multi-layered, come in various types for different applications, and are crucial for image quality, durability, and overall display functionality.

Related Articles:

What Is CRI and Why Does It Matter for LCD Backlights?

How Can You Program a Graphic LCD Module to Show Custom Graphics?

What Is the Purpose of Multiplexing in LCDs?

How Do You Choose the Best Microcontroller or Processor for Your LCD Module Project?

What Is Circular Polarization and How Does It Improve LCD Displays?

FAQ

Why are LCDs polarized?

LCDs are polarized to control light direction, allowing the liquid crystals to create visible images by twisting light’s polarization.

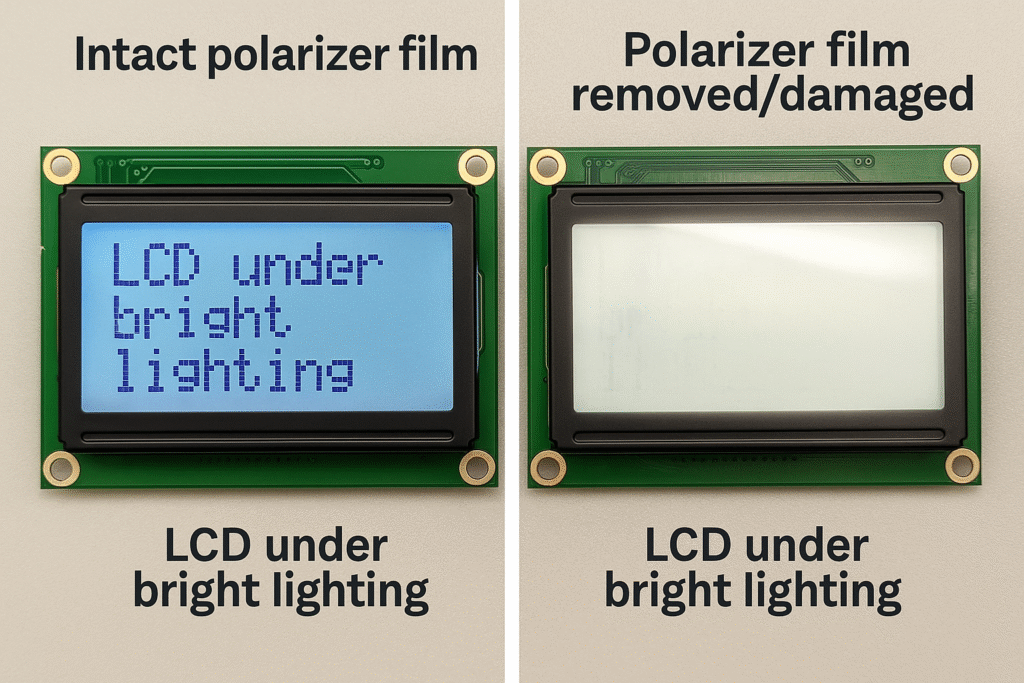

Can an LCD work without a polarizer film?

No – without polarizer films, an LCD cannot form a visible image. The screen would just show a blank (often white or grey) glow because the liquid crystals would have no fixed light orientation to modulate. Polarizers are absolutely required for the LCD’s light control mechanism.

What happens if I remove the polarizer from an LCD screen?

If you remove the front polarizer from an modern LCD, the display will look uniformly bright and featureless (no visible content). The image is still being generated as polarized light, but without the final polarizer, our eyes can’t distinguish it. You’d need to view the screen through another polarizing filter (like polarized sunglasses) to see the hidden image.

Are LCD polarizer films replaceable if they get damaged?

Yes. In fact, I have often replaced scratched or burnt polarizer films on LCD panels. You can peel off the old polarizer (which is glued on with an adhesive layer) and stick a new polarizer film of the correct type. This can restore the display’s clarity and functionality without having to replace the entire LCD module. It’s a delicate process but feasible with the right tools.

Do other display types (like OLED) use polarizers too?

Many OLED displays also use polarizer films. Even though OLEDs emit their own light (unlike LCDs which use a backlight), a circular polarizer layer is often added to OLED screens to reduce reflections and improve contrast. This polarizer cuts out ambient light reflections off the OLED panel, making blacks appear truly black by blocking external light – a similar principle of controlling polarization for better image quality.