Liquid‑crystal displays (LCDs) rely on thin liquid‑crystal layers sandwiched between transparent electrodes and polarizing filters. The crystals twist under an applied electric field to modulate light. These panels are designed for indoor environments where ambient lighting and temperature are controlled. In direct sunlight, ultraviolet radiation and heat can trigger chemical changes in the liquid‑crystal molecules, polarizers and adhesives and lead to visible degradation. This article explains how ultraviolet light and heat affect LCD modules, what signs indicate damage and how outdoor‑readable LCDs differ from standard displays.

How does ultraviolet radiation degrade liquid crystals and polarizers?

Ultraviolet (UV) photons have energies high enough to break chemical bonds in the organic components used in LCDs. Modern LCDs use cyanobiphenyl‑based liquid crystals; the molecules are arranged in long chains and doped with dyes and alignment layers. When exposed to strong UV radiation, several damaging mechanisms occur:

-

Chemical bond breakage and fragmentation – High‑energy UV photons break chemical bonds in the long chains of liquid‑crystal molecules, causing molecular fragmentation. The disruption of molecular alignment reduces the crystal’s ability to respond to driving voltages and impairs display performance. Prolonged UV exposure also lowers the threshold voltage of the liquid crystal molecules, making them less responsive to the applied electric field and further degrading contrast.

-

Decrease in electrical resistance and increased power consumption – Short‑term UV exposure can decrease the electrical resistance of LCD components and increase power consumption. The panel must draw more power to maintain a given brightness, which accelerates wear.

-

Yellowing, faded colors and black spot formation – Long exposure leads to chemical degradation of dyes and alignment layers, causing color shifts and a washed‑out appearance. UV damage may also produce a yellow tint. When liquid‑crystal molecules stop functioning, the screen can develop permanent black spots. These spots result from local failure of the liquid crystal and are often irreversible.

-

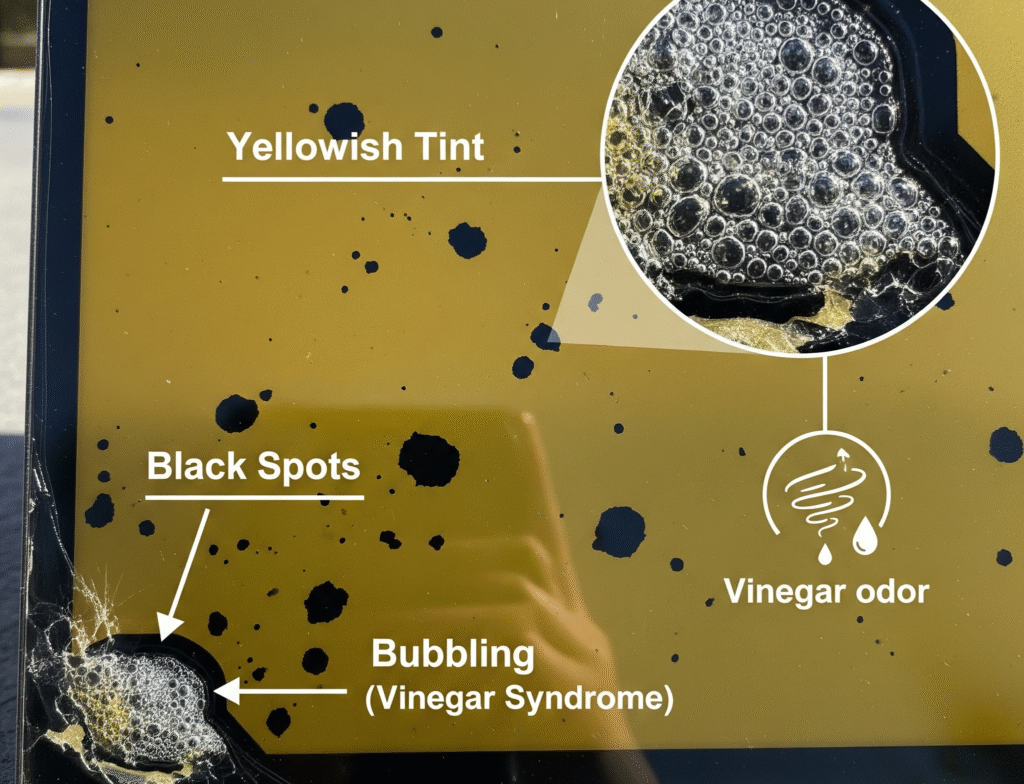

Polarizer degradation – The polarizing filters used to block specific polarization states are typically thin polyvinyl‑alcohol films doped with iodine. Polarizer films are used to block most UV light, but their aging performance is relatively low, particularly above 95 °C. Without UV protection, displays lose brightness and quality, and the polarizer materials themselves yellow over time. Over decades, the adhesives bonding the polarizer to the LCD can hydrolyze into acetic acid (“vinegar syndrome”), causing bubbling, cracking and warping. Heat and humidity accelerate this process.

-

Combined UV and infrared (IR) degradation – The organic components of liquid crystals are susceptible to UV (<400 nm) and IR (>750 nm) radiation. Extended exposure causes a color shift and washed‑out images. The UV and IR radiation degrade the materials until they fail.

How does heat from sunlight cause temporary or permanent blackouts?

Infrared radiation from sunlight heats the LCD stack. When the temperature of the liquid crystal approaches or exceeds its clearing point (the temperature at which it becomes an isotropic liquid), the display can black out. Different failure modes include:

-

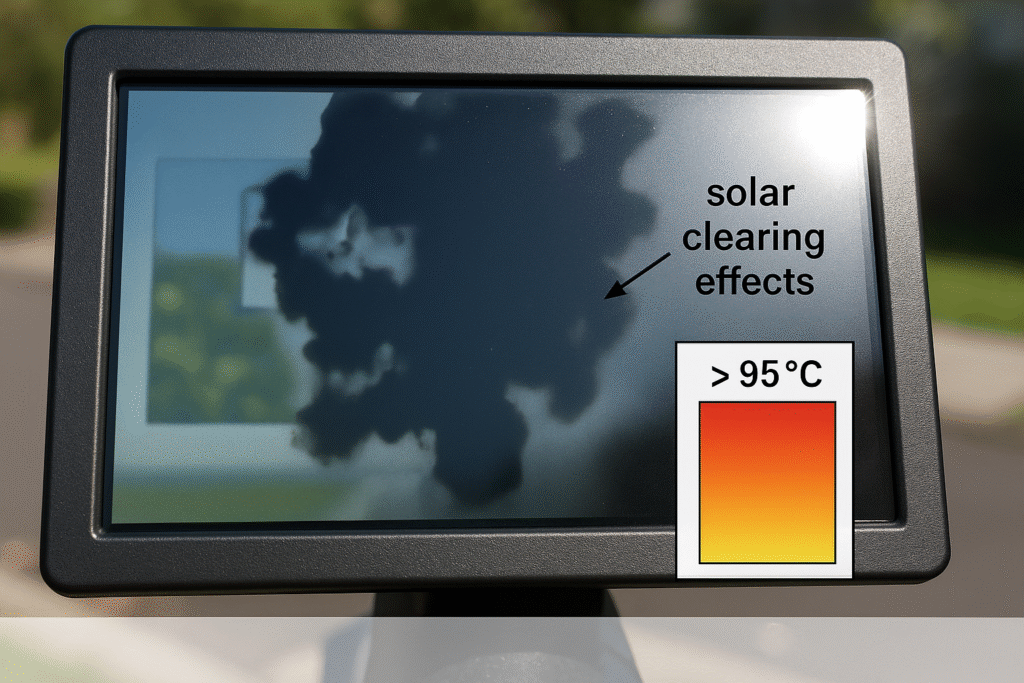

Overheating and solar clearing – Excessive heat causes the liquid crystals to become isotropic, leading to complete failure of the display. Solar clearing occurs when the liquid crystals boil or reach their clearing point, producing black blotches on the screen. These blotches indicate regions where the liquid crystals no longer align.

-

Temporary blackout and recovery – Repeated cycles of high temperature and UV exposure can cause temporary blackouts; once the temperature drops, the liquid crystals may temporarily recover. However, continued exposure leads to permanent molecular damage and irreversible black spots.

-

Failure of adhesives and polarizer – When the LCD heats above 95 °C, the polarizer’s aging performance declines. Adhesive failure can cause delamination or bubbles (vinegar syndrome), and the display may appear dark or blotchy. Heat also accelerates hydrolysis of adhesives.

Does sunlight glare or reduced contrast permanently damage LCD modules?

Glare and reflections from sunlight impair readability, but they do not directly damage the LCD’s internal components. A sunlight‑readable monitor manufacturer explains that standard monitors fail in bright conditions because the environment’s brightness overwhelms the backlighting. The screen appears washed out, and reflective surfaces create mirror‑like glares. These effects are optical and do not degrade the liquid crystals or polarizers. However, if high ambient light leads to the user increasing backlight brightness to compensate, it can accelerate backlight aging and heat generation. The physical damage arises primarily from UV radiation and heat, not from glare itself. Anti‑glare coatings and proper brightness management can mitigate these optical problems without affecting the display’s longevity.

What signs indicate sunlight‑induced damage in LCD modules?

Users can recognise sunlight‑induced damage through several visible and functional symptoms:

-

Faded or shifted colors – UV exposure causes color dyes to bleach, leading to dull or washed‑out colors. Reds and yellows are especially susceptible.

-

Yellowing of the screen – Chemical changes in the polarizer or adhesive produce a yellowish tint. This is a common sign of UV degradation.

-

Black spots or blotches – Prolonged heat or UV exposure causes local failure of liquid‑crystal regions, resulting in permanent black spots or blotches. Black spots can develop after threshold‑voltage reduction and molecular damage.

-

Increased power consumption – UV exposure can decrease electrical resistance and increase power consumption, indicating that the display must work harder to maintain brightness. A rise in power usage is a warning sign.

-

Screen flickering or inconsistent color – Degradation of liquid crystals or adhesives can cause flickering and inconsistent color display.

-

Vinegar odor and bubbling polarizer – Vinegar syndrome produces a vinegar-like smell and visible bubbling or cracking of the polarizer film. This indicates adhesive breakdown accelerated by heat and humidity.

How can LCD modules be protected from UV and heat damage?

Several strategies can mitigate sunlight‑induced degradation:

-

Use UV‑blocking coatings or filters – Applying UV‑blocking films on the screen can filter out harmful UV radiation while allowing visible light to pass. UV‑blocking coatings or filters reduce direct UV damage and extend screen life. Tesa has developed optically clear adhesives that block UV light below 380 nm while transmitting more than 99 % of visible light, addressing the low aging performance of traditional polarizers.

-

Proper placement and shading – Avoid placing LCD modules in direct sunlight; if outdoor installation is necessary, use shades, awnings or protective casings to block intense sun. Protective enclosures reduce UV and IR exposure and can include UV‑blocking glass.

-

Cooling solutions and heat dissipation – Incorporate active ventilation, heat sinks or high‑performance fans to dissipate heat build‑up. An optimized cooling system prevents the liquid crystals from reaching their clearing point. Some designs use liquid cooling or additional ventilation channels.

-

Select high‑temperature‑resistant materials – Choosing liquid‑crystal formulations and polarizers rated for high temperatures improves resistance to solar heating. Outdoor LCDs may employ high‑temperature liquid crystals and UV‑blocking polarizers.

-

Regular maintenance and cleaning – Maintain cooling systems and keep screens clean; dust accumulation can trap heat. Inspect for scratches or damage to protective coatings and repair them promptly.

-

Optical bonding – Bonding the LCD panel to the cover glass with a clear adhesive eliminates the air gap, reducing internal reflections and improving heat dissipation. Optical bonding also adds structural strength and prevents moisture intrusion. AbraxSys emphasises that optical bonding enhances contrast and clarity while supporting thermal management.

-

Use hot‑mirror filters – Using a hot mirror with a UV blocker. A hot mirror reflects infrared and UV wavelengths, reducing the amount of IR radiation between 750–1200 nm and UV below 400 nm that reaches the display. Extended hot mirrors can protect up to 1600 nm.

What features make outdoor‑readable LCD modules different from standard displays?

Outdoor‑readable (sunlight‑readable) LCD modules are engineered to maintain visibility and longevity under extreme conditions. Key differences include:

High brightness and contrast

Standard LCD monitors provide 200–350 nits of brightness, which is easily overwhelmed by sunlight. Sunlight‑readable monitors incorporate high‑brightness LED backlights with outputs of 1,000 nits or more. This high luminance overpowers ambient light and preserves visibility. The backlight design also emphasises energy efficiency and thermal management to handle the added heat(What Makes an LCD Sunlight Readable?).

Optical bonding and anti‑reflective coatings

Outdoor displays often use optical bonding to glue the LCD stack to the cover glass, eliminating air gaps and reducing internal reflections. This process improves contrast and prevents moisture intrusion or fogging. They also employ anti‑reflective (AR) and anti‑glare (AG) coatings. AR coatings increase light transmission and minimize mirror‑like reflections, while AG coatings diffuse sunlight across the surface to improve readability from various angles.

Wide operating temperature range and rugged construction

Outdoor‑readable displays must operate reliably in harsh environments. Models are designed to withstand temperatures from –30 °C to +80 °C. Rugged enclosures protect against vibration, moisture and dust. These displays use high‑temperature liquid crystals, UV‑blocking polarizers and durable adhesives to maintain performance(What Temperature Range Can LCD Modules Safely Operate In?).

UV‑resistant polarizers and adhesives

Outdoor‑readable modules incorporate UV‑resistant polarizer films or replace film polarizers with wire‑grid polarizers that resist UV degradation. They may also use optically clear adhesives with UV‑blocking additives to protect the underlying layers. Some units include hot mirrors or cold mirrors to reflect IR and UV energy, reducing thermal load.

Integrated thermal management

To prevent solar clearing and maintain long‑term reliability, outdoor modules integrate heat sinks, internal fans or heat‑dissipating materials. The design ensures the liquid crystal temperature stays below its clearing point even under direct sunlight.

Enhanced brightness/contrast control and sensors

Outdoor displays may include ambient light sensors to adjust backlight intensity automatically. This optimises readability while minimizing power consumption. Some modules also employ dynamic backlight control with reflective polarizers to improve efficiency.

Conclusion

Ultraviolet radiation and heat from sunlight can significantly degrade the performance and lifespan of LCD modules. UV photons break chemical bonds in the liquid‑crystal molecules, reduce electrical resistance, lower threshold voltages and discolor polarizers. Infrared heat can cause the liquid crystals to reach their clearing point, resulting in temporary or permanent blackouts. Visible signs of sunlight‑induced damage include faded colors, yellowing, black spots, increased power consumption and polarizer bubbling.

FAQ

Can LCD modules be repaired after UV or heat damage?

Most UV or heat damage is irreversible. Prevention is much easier than repair.

Will a shade or visor help with sunlight exposure?

Yes, simple shading reduces both UV and IR exposure, extending LCD life.

Is optical bonding necessary for outdoor LCDs?

For the best visibility and reliability outdoors, optical bonding is highly recommended.

Can I use standard indoor LCDs outside with extra protection?

Not reliably—standard modules lack essential materials for outdoor survival and will degrade faster.

What is “vinegar syndrome” in LCDs?

It is a chemical breakdown of adhesives, often caused by heat and UV, leading to a vinegar-like odor and delamination.