Are you struggling to find a display that fits your product perfectly? Off-the-shelf options can be limiting. Designing your own custom segment LCD gives you total control over form and function.

I remember a client, he owns a company making Ebike displays. He was frustrated because standard LCDs didn’t match his product’s unique look. We designed a custom one from scratch, and it was a game-changer for his brand.

What Types of Segment LCD Technologies Are Available?

Before you start designing, you need to know your options. The technology you pick affects cost, appearance, and performance. Let’s look at the main types for segment displays.

The main technologies are TN, HTN, STN, FSTN, and VA, which are all monochrome LCD types. Your choice will depend on your needs for viewing angle, contrast, and overall display complexity(What Are the Key Differences Between TN, STN, and HTN LCD Technologies?).

Understanding Your Options

When we talk about passive displays, there are a few categories. It’s good to know where segment LCDs fit in.

Display Types Explained

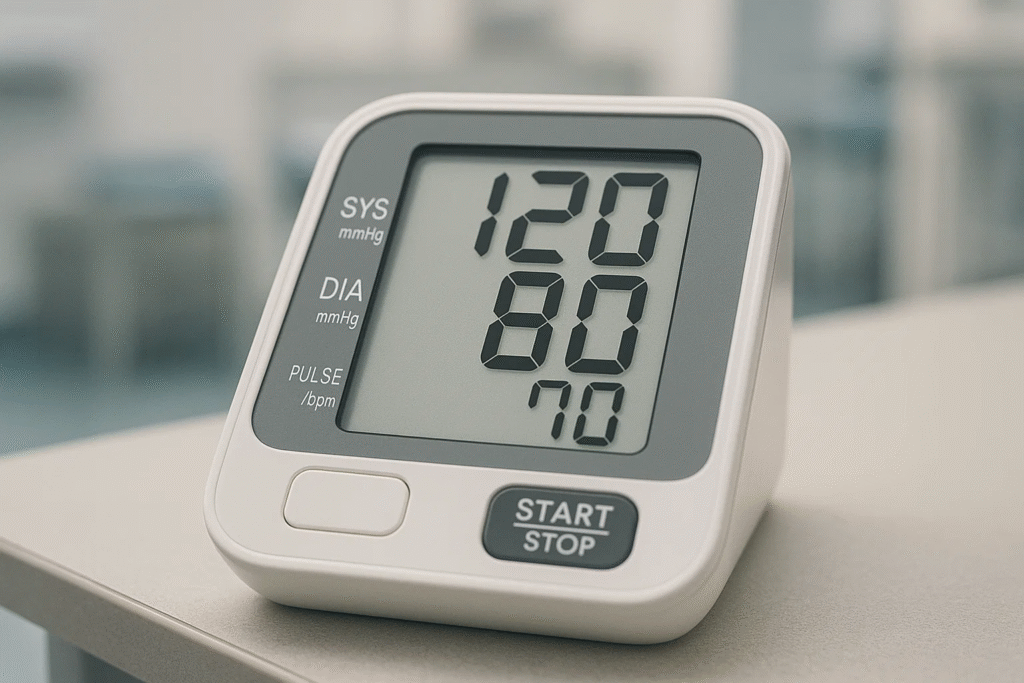

Segment displays are the simplest, showing fixed numbers and icons, like on a calculator or gas pump. They are great for low-cost, specific functions. Other types include alphanumeric displays, which show letters and numbers, and graphic displays, which can show any image. For most custom, cost-effective applications, segment displays are the best choice(What is a Monochrome LCD Display).

Comparing Core Technologies

Each technology offers different visual characteristics. While the sources list them, here’s a breakdown from my 13 years of experience to help you choose(How Do TN, IPS, and VA LCD Panels Affect Backlighting System Design?).

| Technology | Key Feature | Best For |

|---|---|---|

| TN (Twisted Nematic) | Fastest response time, low cost. | Standard applications with a direct viewing angle. |

| HTN (High Twisted Nematic) | Better viewing angle and contrast than TN. | Devices where users might view from slight angles. |

| STN (Super-Twisted Nematic) | Higher contrast and wider viewing angles. | More demanding industrial or medical devices. |

| FSTN (Film-compensated STN) | Superior contrast and a sharper look. | High-end instruments that need a crisp display. |

| VA (Vertical Alignment) | Highest contrast ratio, true black background. | Premium products where visual quality is critical. |

Display Modes

You also need to choose a display mode based on your product’s lighting conditions(What Sets Transmissive, Reflective, and Transflective LCDs Apart?):

- Reflective: Uses ambient light to be seen. Perfect for outdoor use and saves power as no backlight is needed.

- Transmissive: Requires a backlight to be visible. Best for products used mainly indoors or in the dark.

- Transflective: A hybrid. It reflects ambient light but also has a backlight for dark conditions, offering the most flexibility.

How Do You Plan and Define the Segment Layout?

This is the creative part where your idea becomes a visual plan. A good layout is essential for a display that’s easy to read and use.

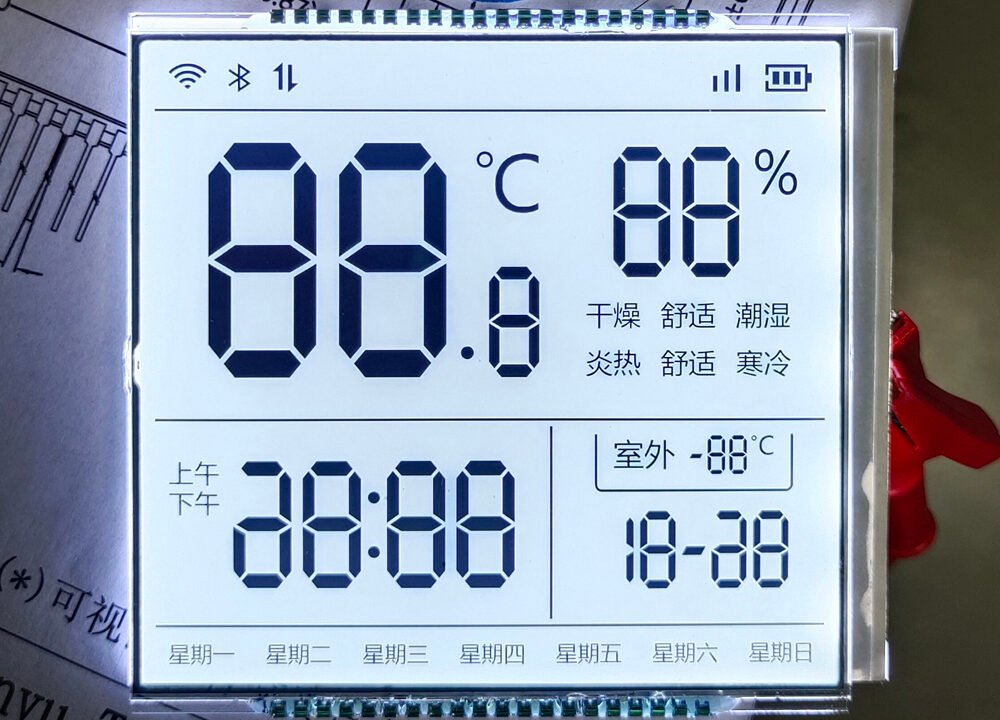

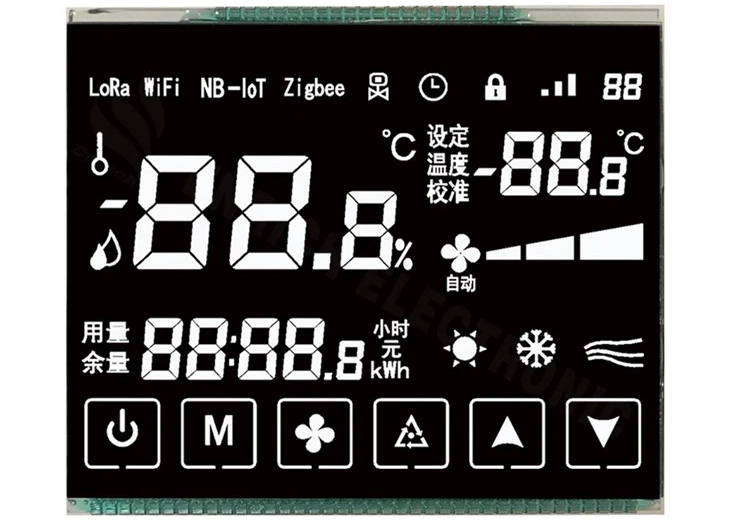

To plan your layout, you must decide what information to show, like numbers or icons, and how to arrange them. This custom blueprint ensures the display perfectly matches your product’s function.

From Sketch to Specification

I always tell my clients to start with a simple pen-and-paper sketch.

What to Include in Your Sketch

Think about every piece of information your user needs to see.

- How many digits do you need?

- What icons are necessary? (e.g., battery level, signal strength, warning symbols)

- Where should they be placed for the best readability?

This initial drawing is the foundation of your design. We at Hua Xian Jing even offer free design help to turn your sketch into a professional prototype plan.

Defining the Physical Glass

Once the layout is set, we define the physical specifications.

- Viewing Area (VA): The part of the display that is visible.

- Overall Dimensions: The total height and width of the glass.

- Connection Method: Where the pins or flex cable will attach.

This process guarantees that the final product is exclusive to you and your application.

What Materials and Fabrication Methods Should You Consider?

The materials you select will define your LCD’s durability, clarity, and performance in different environments. Let’s look at the key components.

Key choices include the LCD technology (like STN or VA), the polarizer type (reflective, transflective), operating temperature range, and the connection method (pins, FPC, etc.).

Building a Robust Display

Your choices here will impact how the display performs in the real world.

Temperature Range

Will your product be used in an office or outside in the winter? You can choose a temperature range that fits your needs(The Effect of Temperature on the Functional Performance of LCD Modules).

- Standard: -20°C to 70°C

- Industrial: -30°C to 80°C

- Harsh Environment: -40°C to 90°C or even wider.

How Do You Integrate Backlighting and Power Management?

A backlight makes your display readable in the dark, but it uses power. Let’s talk about how to get the best of both worlds.

You can add a backlight for low-light use. To manage power, use a transflective polarizer, dim the backlight with PWM, or use low-power microcontrollers to extend battery life significantly(How Does PWM Control Backlight Brightness in Modern Displays?).

Balancing Visibility and Battery Life

Power consumption is a huge concern for portable devices. Luckily, segment LCDs are very efficient.

Power-Saving Strategies

- Go Backlight-Free: A positive mode display with a reflective polarizer is readable in bright light and uses almost no power, often under 1mA.

- Use PWM: If you need a backlight, you can use Pulse Width Modulation (PWM) to control its brightness. This allows you to dim it in bright conditions or turn it off completely to save power.

- Efficient Designs: I’ve worked on designs that can run for over 3 years on a single coin cell battery. It’s all about making smart choices in the design phase.

Voltage Needs

Most segment displays operate at a standard voltage of 3.3V or 5V. Some advanced microcontrollers even have built-in charge pumps, or voltage boosters, to enhance the display contrast without needing extra components(What Is the Right Way to Use Level Shifters With 3.3V LCD Modules in 5V Systems?).

How Do You Control a Segment LCD with a Microcontroller?

Your display is just glass until a “brain” tells it what to show. That brain is a microcontroller, or MCU.

The most efficient method is using a microcontroller with an integrated LCD segment driver. This single-chip solution reduces cost, saves board space, and simplifies the overall design.

The Brains of the Operation

Using an MCU with a built-in driver has become the industry standard.

Why an Integrated Driver is Better

In the past, you needed a separate driver chip to talk to the LCD. Integrating it into the MCU offers several advantages:

- Lower Cost: One chip is cheaper than two.

- Smaller Size: Saves valuable real estate on your PCB.

- Simpler Assembly: Fewer components to solder.

- More Flexibility: Gives you more direct software control over segments.

Popular MCUs for LCD Control

Many major manufacturers offer MCUs with integrated LCD drivers. Here are a few examples my clients often use:

| Manufacturer | Model Series | Segment Control Capability |

|---|---|---|

| Microchip | PIC16F91x family | Drives up to 96 segments |

| Texas Instruments | MSP430F4xx family | Drives up to 160 segments |

| ST Microelectronics | STM32L15xxx family | Drives up to 160 segments |

| NXP | LPC12D27 | Drives up to 160 segments |

These MCUs also offer great features like low-power sleep modes that keep the display on while the rest of the system saves power.

How Do You Move From Prototype to Mass Production?

Your prototype is approved and works perfectly. Now it’s time to scale up production. Let’s look at what that involves.

Moving to mass production typically requires a Minimum Order Quantity, or MOQ. For most custom displays, this is around 1,000 units, as it allows for efficient use of the assembly line.

Scaling Your Design

I often speak with clients who need to replace a discontinued part from another supplier. We have to design a custom solution, which always involves an MOQ.

Why MOQs are Necessary

Custom LCDs are manufactured for a single customer. To set up our 28 production lines and run them efficiently, we need to produce in larger batches. This is why we have a 1,000-piece MOQ. However, we always start with a smaller sample run for you to test and validate the design first.

Our Production Timeline

Once you approve the prototype, we move quickly.

- Samples: Take up to 7 days.

- Bulk Production: Takes up to 30 days.

We pride ourselves on our factory strength and delivery speed, which I know is a key point for buyers in America and Germany.

How Can You Customize Your LCD Beyond Standard Designs?

A custom design is more than just the segments. You can add color and branding to make your product stand out on the shelf.

Beyond the layout, you can add custom color silk-screen printing to the glass. This allows you to include logos, colored borders, or other graphics, creating a truly exclusive design.

Making Your Display Unique

This is how you take a functional display and make it part of your brand identity.

The Power of Color Silk-Screening

With silk-screening, we can print permanent, colorful designs directly onto the LCD glass. Imagine:

- Your company logo in the corner.

- A red border around a warning icon.

- A green background for a “power on” indicator.

This adds a professional, polished look that can’t be achieved with a standard display.

Guaranteeing Exclusivity

When we create a custom design with you, it is for you alone. We guarantee that the design is exclusive and won’t be offered to any other customer. This protects your unique product and gives you a competitive advantage.

Conclusion

Designing a custom segment LCD puts you in the driver’s seat. Following these steps helps you create a unique, efficient, and perfectly tailored display for your product.

FAQ

What is the lead time for a custom segment LCD?

Most custom segment LCD projects take about 15 days for samples and 30 days for mass production once the design is finalized.

What is the cost impact of adding a backlight to a segment LCD?

Adding a backlight increases costs due to additional components, but using PWM and transflective polarizers can minimize power consumption, balancing expenses.

How do I ensure my custom LCD meets regulatory standards for my industry?

We provide compliance support for standards like RoHS and REACH, ensuring your LCD meets industry-specific regulations for markets like America and Germany.

What if my supplier cannot scale production for my growing demand?

Hua Xian Jing’s 28 production lines and 1,300+ workers ensure scalable production, delivering up to 300,000+ units within 30 days to meet your needs.

Can I integrate my custom LCD with existing electronics without redesigning my PCB?

Our flexible connection options, like FPC or zebra strips, allow seamless integration with your existing PCB, minimizing design changes.