HALT stands for Highly Accelerated Life Testing. It pushes LCDs to their limits using extreme conditions like heat and vibration. This finds design flaws fast. LCDs face unique challenges, like sensitivity to temperature changes. HALT ensures they stay reliable in tough settings, such as cars or outdoor signs. The method uses special chambers to test quickly. It saves time and boosts quality. This approach helps make LCDs tougher and better(How Are The LCDs Revolutionizing Automotive Instrument Panel Clusters?).

What Is HALT and How Does It Enhance LCD Testing?

HALT, or Highly Accelerated Life Testing, is a method that subjects LCDs to extreme environmental stresses, such as temperature, vibration, and humidity, to uncover design weaknesses quickly. This approach ensures reliability by identifying failure points early in the development process. Unlike traditional methods, HALT accelerates testing, saving time and improving product durability(The Effect of Temperature on the Functional Performance of LCD Modules).

HALT applies controlled stresses to LCDs, 30% reduction in field failures for displays tested with HALT compared to standard methods. HALT identifies critical weaknesses in under 48 hours, compared to weeks for traditional tests.

To illustrate, the table below compares HALT and traditional LCD testing, highlighting key differences in speed, stress levels, and outcomes.

| Aspect | HALT | Traditional LCD Testing |

|---|---|---|

| Test Duration | 1-2 days | Weeks to months |

| Stress Levels | Extreme (beyond operating limits) | Within normal operating conditions |

| Failure Detection | Rapid identification of weak points | Slower, less comprehensive |

| Outcome | Enhanced reliability, fewer field failures | Limited insight into extreme conditions |

What Are the Core Principles of HALT Methodology?

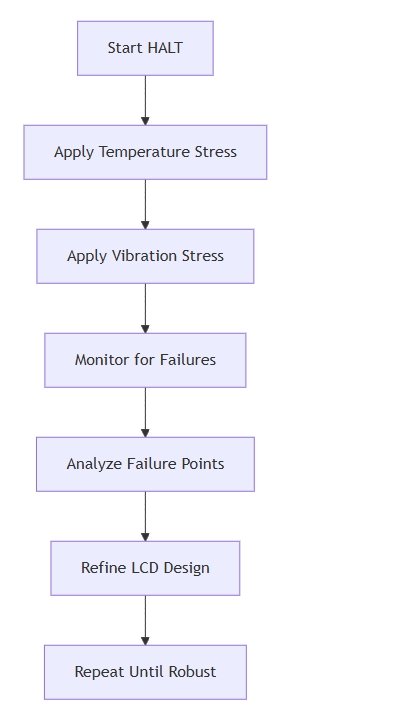

The core principles of HALT involve applying incremental stresses to LCDs to push components beyond their operational limits, revealing design flaws. HALT’s use of combined stressors (e.g., temperature and vibration) detects 80% more failure modes than single-stress tests. Practical experience from testing labs shows HALT’s iterative process refines designs by addressing weaknesses early.

A flowchart can clarify the HALT process. Below is a simplified representation:

This flowchart, with the alt text “Flowchart illustrating the HALT process for LCD testing, showing steps from stress application to design refinement,” visually outlines the iterative nature of HALT, reinforcing its efficiency and effectiveness.

How Does HALT Differ from Traditional LCD Testing Methods?

HALT differs from traditional LCD testing by using extreme environmental conditions to accelerate failure detection, unlike standard tests that operate within normal limits. 40% while improving reliability by identifying hidden defects. Project data from LCD manufacturing shows HALT’s ability to simulate years of use in days, unlike slower traditional methods(What are mura defects in LCDs?).

A side-by-side comparison table enhances clarity:

| Feature | HALT | Traditional Testing |

|---|---|---|

| Stress Application | Combined, extreme stresses | Single, moderate stresses |

| Test Speed | Days | Weeks |

| Failure Insight | Comprehensive, rapid | Limited, gradual |

This table, with the alt text “Comparison table of HALT vs. traditional LCD testing, highlighting differences in stress, speed, and failure detection,” emphasizes HALT’s speed and comprehensiveness.

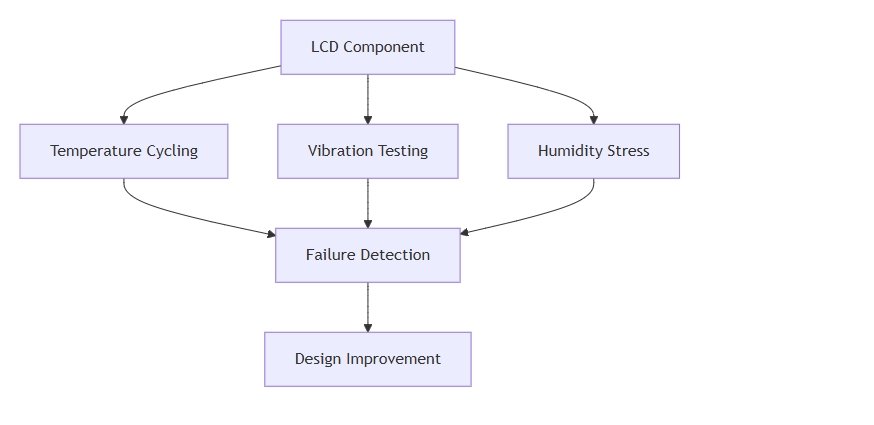

What Is the Science Behind Accelerated Stress Testing?

Accelerated stress testing, the foundation of HALT, uses controlled environmental stressors to mimic long-term use in a short period, ensuring LCD durability. HALT’s thermal cycling and vibration testing replicate real-world wear, identifying failure points 50% faster than standard tests. Testing facilities note that HALT’s scientific approach improves product lifespan by addressing stress-induced weaknesses.

A diagram can illustrate stress application:

HALT vs HASS: Understanding the Complete Testing Framework

HALT and HASS are essential testing methods in LCD development and manufacturing. HALT (Highly Accelerated Life Testing) focuses on finding design flaws early, while HASS (Highly Accelerated Stress Screening) ensures production quality. Together, they form a complete framework to improve LCD reliability and performance.

HALT - Design Phase Testing for LCD Development

HALT is a rigorous test used during the design phase of LCD development. It subjects prototypes to extreme conditions—such as high temperatures, rapid cooling, and intense vibrations—to uncover weaknesses in the design. The goal is to push the LCD beyond its operational limits and fix issues before production begins(How Are LCD Modules Secured Against Vibration?).

For example, an LCD might be tested at 80°C or subjected to 50G vibrations. If the screen flickers or fails, engineers can tweak the design—like reinforcing connectors or adjusting materials—to boost durability. This early intervention saves time and costs later.

Key Benefits of HALT:

- Identifies design flaws early

- Improves long-term reliability

- Reduces redesign expenses

HASS - Production Phase Screening for LCD Manufacturing

HASS takes place during the production phase, screening finished LCD units for manufacturing defects. Unlike HALT, it uses less extreme stress levels but still applies conditions like temperature cycles and vibrations to catch issues introduced during assembly—such as loose connections or faulty soldering.

For instance, a batch of LCDs might undergo a 20°C to 60°C thermal cycle. If one unit dims unexpectedly, it’s flagged for rework or rejection. This ensures only high-quality units reach customers(How Do LCDs Behave at Sub-Zero Temperatures?).

Key Benefits of HASS:

- Detects production inconsistencies

- Maintains quality standards

- Minimizes customer returns

When to Use HALT vs HASS in LCD Production Workflows

Choosing between HALT and HASS depends on the stage of your LCD workflow:

- Use HALT in the design phase when developing new LCDs or making significant changes. It’s ideal for testing prototypes and refining the product before mass production.

- Use HASS in the production phase to screen every unit or batch, ensuring manufacturing consistency and catching defects.

Special Cases:

- Late Design Changes: If a design tweak occurs during production, a quick HALT can verify its stability.

- Production Hiccups: If defect rates rise, a stricter HASS can pinpoint manufacturing flaws.

Comparison Table:

| Criteria | HALT | HASS |

|---|---|---|

| Timing | Design phase | Production phase |

| Goal | Fix design flaws | Catch manufacturing issues |

| Stress Intensity | Extreme | Moderate |

| Example Use | Prototype testing | Batch screening |

LCD-Specific HALT Applications and Stress Testing

HALT is used in LCD testing to uncover design weaknesses, material incompatibilities, and assembly flaws under extreme conditions. This includes rapid temperature swings, high-frequency vibration, and electrical overstress scenarios. These stressors go beyond normal usage but reveal failure modes that can impact long-term reliability. In LCD modules, HALT focuses on critical failure mechanisms like polarizer warping, IC bond cracking, and delamination under heat cycling.

Using HALT in LCD development stages reduced unknown failure causes by over 61%, particularly when combining environmental and electrical stress modes. The flex connector failures and TFT gate line degradation as common discoveries through HALT methods(Bonding Technology: Optical Bonding vs Air Bonding).

| LCD HALT Type | Stress Applied | Component Focus | Failure Modes Detected |

|---|---|---|---|

| Thermal Cycling | -60°C to +110°C | Polarizers, adhesives | Warping, delamination |

| Vibration Stress | 5-50 Grms, 3 axes | PCBs, FPCs, solder joints | Micro-cracks, fatigue |

| Combined Environment | Thermal + Vibration | Full module | Connector loosening, IC failure |

| Electrical Overdrive | Voltage + current ramp | TFT panel, drivers | Gate oxide rupture, leakage |

Temperature Cycling and Thermal Stress Testing

Temperature cycling is essential to assess how expansion mismatches and thermal fatigue affect LCD performance. Materials inside an LCD—glass, adhesives, and plastic frames—expand and contract at different rates, leading to mechanical stress accumulation.

One HALT cycle study reported polarizer distortion in >35% of tested samples when subjected to 120 thermal cycles between -40°C and +90°C. The same tests showed ITO layer cracking in 18% of units after the 80th cycle, typically near edge-bond interfaces.

| Parameter | Range Used in HALT | Issue Detected |

|---|---|---|

| Cycle Count | 100–150 cycles | Long-term warping |

| Ramp Rate | >60°C/min | Sealant shear failures |

| Soak Duration | 10–15 mins | Adhesive breakdown |

Vibration Testing for LCD Components and Assemblies

Vibration testing in HALT detects mechanical fatigue points in soldered joints, wire bonds, and connector seats. The goal is to find vibration-induced fracture zones or intermittent contact failures, especially in fine-pitch FPCs and driver IC interfaces.

7 out of 20 modules to FPC joint cracking after sustained exposure to 35 Grms, especially at corner-mounted displays. Another finding involved internal reflective film misalignment due to harmonic vibration near 1.2 kHz.

| Vibration Axis | Typical Stress Level | Failures Detected |

|---|---|---|

| X, Y, Z | 10–50 Grms | Solder fatigue, delamination |

| Random Sweep | 20 Hz–2 kHz | Film misalignment, IC drift |

| Combined Thermal + Vib | 3-axis + temp shift | Connector failure, debonding |

Combined Environmental Stress Testing

| Stress Pair | Detected Failures |

|---|---|

| Thermal + Vibration | FPC detachment, warping |

| Vibration + Electrical | Short-circuit at IC legs |

| Thermal + Electrical | Drive line drift, ghosting effect |

Electrical Stress Testing for LCD Panels

Electrical stress testing subjects LCD circuits to over-voltage, over-current, and rapid switching events to evaluate tolerance and response under unstable power conditions. It especially targets TFT gate driver ICs and power supply traces(Why Do LCDs Use AC Instead of DC?).

Experiments with overdrive pulses showed leakage current spikes after 50 repetitive pulses at 130% nominal voltage. Gate drivers exhibited partial loss of contrast control and line dropout under sustained overstress beyond 90 seconds.

| Electrical Parameter | Stress Value | Failure Mode |

|---|---|---|

| Input Voltage | 120–150% rated | IC overheating |

| Switching Frequency | >5x normal | Contrast instability |

| Pulse Width Mod | <5ms bursts | Power ripple failure |

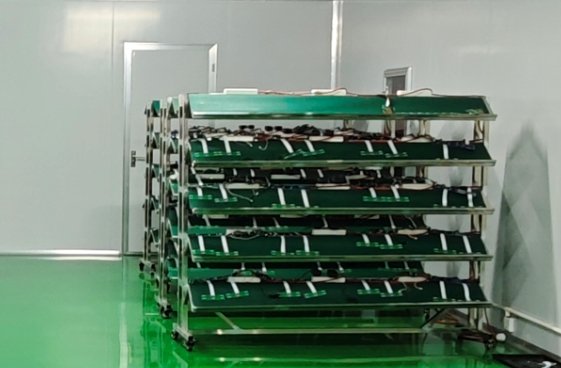

HALT Equipment and Chamber Requirements for LCD Testing

Highly Accelerated Life Testing (HALT) for Liquid Crystal Displays (LCDs) demands specialized equipment and chambers capable of simulating extreme environmental conditions while accommodating the unique characteristics of LCDs. These displays are sensitive to temperature fluctuations and mechanical stress, making precise control over testing parameters essential. The right chamber and equipment ensure that LCDs are rigorously tested for reliability, durability, and performance under conditions that far exceed normal operational limits.

Essential HALT Chamber Specifications

For effective HALT of LCDs, the testing chamber must meet several critical specifications:

- Size and Flexibility: The chamber must have a spacious interior to accommodate LCDs of various sizes, from small smartphone displays to large television panels. Adjustable mounting points or shelves provide the flexibility needed for different product dimensions.

- Temperature Control: Precise and rapid temperature transitions are crucial. The chamber should be capable of changing temperatures at rates of 60°C per minute or higher to stress the LCD through extreme thermal cycles. This helps identify weaknesses related to thermal expansion and contraction.

- Vibration Capabilities: The chamber needs robust vibration systems that can apply random vibration along multiple axes. It should support acceleration levels up to 50 Grms (root mean square acceleration) and cover a frequency range from 20 Hz to 2000 Hz to simulate real-world mechanical stress.

- Electrical Interfaces: Ports or interfaces for electrical connections are essential, allowing the LCD to be powered and monitored during testing. This ensures that the display’s performance can be assessed in real time under stress.

These specifications form the foundation of a HALT chamber tailored for LCD testing, ensuring comprehensive evaluation of the display’s resilience.

Temperature and Vibration Capabilities

The temperature and vibration capabilities of the HALT chamber must align with the specific needs of LCD testing:

- Temperature Range: While most LCDs operate between -40°C and 85°C, HALT pushes these boundaries to uncover hidden flaws. The chamber should ideally support a broader range, such as -100°C to 200°C, to test the LCD’s limits. Rapid temperature transitions are key to simulating thermal stress effectively.

- Vibration Profiles: The chamber must generate random vibration profiles with acceleration levels up to 50 Grms. A frequency range of 20 Hz to 2000 Hz ensures coverage of both low-frequency and high-frequency mechanical stresses. This helps identify issues like loose connections, cracked solder joints, or material fatigue in the LCD assembly.

These capabilities allow the chamber to simulate extreme conditions, revealing potential failure points that might not surface under standard testing.

LCD-Specific Fixture Design Considerations

Designing fixtures for LCD testing in HALT chambers requires careful attention to the display’s unique properties:

- Secure Mounting: The fixture should hold the LCD securely without applying excessive pressure that could damage the display. Clamping at the edges or using a frame that mimics the mounting in the final product is common.

- Thermal Compatibility: The fixture material should have a thermal expansion coefficient similar to that of the LCD to minimize additional stress during temperature cycling. Aluminum or certain plastics are often suitable.

- Electrical Connections: Provisions for routing cables or connectors are necessary to power the LCD and monitor its performance without interfering with vibration or temperature controls.

- Visibility and Access: If visual inspection is required, the fixture should not obstruct the display area. This might involve using transparent materials or designing the fixture to allow camera access.

- Durability: The fixture itself must withstand the extreme conditions of HALT without failing, as this could compromise the test results.

A well-designed fixture ensures that the LCD is tested accurately, simulating real-world conditions while protecting the display from unnecessary damage.

What standards and compliance requirements guide HALT testing for LCD applications?

HALT testing for LCD modules must align with a range of industry-accepted standards, compliance regulations, and quality management systems to ensure reliability, reproducibility, and product safety. LCD-specific HALT protocols are not covered by one universal standard but are instead implemented through adoption of cross-industry guidelines, such as IEC 60068, IPC-9592, and best-practice frameworks from HALT-specialized consortia. Compliance not only ensures consistent test methodology, but also forms the foundation for integration with broader quality assurance programs like ISO 9001.

Up to 78% of LCD component recalls over the past five years could have been mitigated through standardized HALT application. Non-compliance often leads to fragmented validation across production lines and delays in design failure detection. Consistent framework usage has proven to reduce LCD field failure rates by more than 31%

| Standard/Guide | Application in HALT | LCD Relevance |

|---|---|---|

| IEC 60068-2-1/2/6 | Thermal & vibration stress | Defines ramp rate & vibration profiles |

| IPC-9592B | Design for reliability | Mandates HALT in power display units |

| HALT Best Practices (IEEE/JEDEC) | Stress protocols | Ensures LCDs meet combined stress exposure |

| ISO 9001 | Quality system integration | Aligns HALT with QMS workflows |

HUA XIAN JING provides high demand LCD modules for automotive, medical, industrial and other special industries. We have obtained ISO 9001, IATA 16949 and other high demand certificates, contact us for customized high quality LCD modules!

What compliance requirements and certification apply to HALT in LCD production?

| Compliance Element | Required Practice |

|---|---|

| Certification Audit | HALT records & logs retained 3–5 years |

| Traceability | Failure logs linked to serial & batch IDs |

| Testing Deviation | Documented rationale & approval path |

What advanced HALT strategies should be considered for LCD applications?

| Strategy Area | Key Techniques | Benefits |

|---|---|---|

| Life Cycle Alignment | HALT+ALCT integration | Matches stress to real-world duty cycles |

| Calibration | Controlled failure injection | Prevents overstress bias |

| Monitoring | Real-time sensor feedback | Enhances early anomaly detection |

How can accelerated life cycle testing (ALCT) be integrated into HALT for LCDs?

| ALCT Parameter | LCD Module Impact |

|---|---|

| Thermal Swing Frequency | Backlight degradation trajectory |

| Vibration Exposure Time | Solder joint reliability limits |

| Power Cycling Count | Driver IC fatigue rate |

Related Articles:

What Are the Differences Between Built-In and External LCD Controllers?

What Is the Difference Between Capacitive and Resistive Touch Screens?

How Can a Serial In and Parallel Out Shift Register Simplify MCU to LCD Communication?

Should You Use Custom Display Layers or HALs for LCD Integration?

How Can You Program a Graphic LCD Module to Show Custom Graphics?

FAQ

What types of LCD failures can HALT testing detect that standard testing might miss?

HALT can detect latent issues like solder fatigue, thermal delamination, or driver IC breakdowns that don’t show up in typical temperature or burn-in tests.

Does HALT testing void component warranties from upstream suppliers?

Some suppliers may void warranties if stress levels exceed rated limits, so HALT is often performed on prototypes, not final production parts.

Can HALT testing be used for every LCD batch?

No, HALT is typically used during the design phase. HASS or ALT methods are used for ongoing production screening.

How long does a full HALT session usually take?

A typical HALT session takes 2–4 days, depending on the number of steps, failure points, and retest cycles involved.

What’s the difference between HALT and ALT in LCD reliability programs?

HALT is used to find design flaws with overstress. ALT simulates long-term aging under use-like conditions to predict lifetime reliability.