Capacitive touch screens detect fingers or conductive styluses through electrostatic field changes. Resistive touch screens register pressure from any input, like gloves or styluses, to connect flexible layers. These differences affect device performance and user experience.

Capacitive screens offer high sensitivity and multi-touch, ideal for smartphones and tablets. Resistive screens work in harsh environments, supporting industrial or outdoor uses. Choosing the right technology depends on application needs and budget(How Are Embedded LCDs Used in Human-Machine Interfaces (HMIs) for Industrial Control Systems?).

How Do Capacitive and Resistive Touch Screens Work?

Capacitive and resistive touch screens use different ways to sense a user’s touch. Capacitive touch screens rely on the human body’s natural electrical properties. When a finger touches the screen, it changes the electrostatic field on the surface, and the device measures this change in capacitance. Resistive touch screens depend on pressure. When you press down, two flexible conductive layers inside the screen meet, causing a circuit to complete and sending a signal to the device.

In real-world use, people notice several differences. Capacitive screens only need a light touch. These screens are best for fingers and can sense multiple touches at once (multi-touch support). Resistive screens need a firm press. They work with almost any object, including a stylus, gloves, or even a pencil. However, resistive screens do not support multi-touch. Clarity is higher in capacitive screens because there are fewer layers between the user and the display, giving better optical transparency.

| Feature | Capacitive Touch Screen | Resistive Touch Screen |

|---|---|---|

| Sensing Principle | Electrostatic field, capacitance | Pressure, circuit completion |

| Layer Structure | Conductive layers (glass, ITO) | Flexible conductive layers |

| Touch Sensitivity | Light touch response | Pressure detection |

| Multi-Touch Support | Yes | No |

| Display Clarity | High (optical transparency) | Lower (more layers) |

| Stylus/Finger Compatibility | Finger, some styluses | Finger, stylus, gloves, objects |

What Are the Structure and Operational Principles of Capacitive and Resistive Touch Screens?

Capacitive touch screens have conductive layers like glass with a thin coating of indium tin oxide (ITO)(Why Is ITO Glass Vital for LCD Displays and Touchscreens?). When a finger touches the screen, the electrostatic field changes. This shift in capacitance tells the controller where the touch happens.

Resistive touch screens have two flexible conductive layers facing each other. When you press down, these layers touch and form a closed circuit, letting the device detect the exact spot.

Installers and engineers often find that capacitive panels are more durable because there is no need for movement between layers. In outdoor environments or with gloves, resistive panels are easier to use. For example, public kiosks in winter or industrial settings with tools rely on pressure activation. When using a projected capacitive touch panel, a finger can even activate the screen through a thin layer of glass(Understanding the Differences Between Self, Mutual, and Projected Capacitive Touchscreens).

How Do Sensitivity, Multi-Touch, and Clarity Compare Between Capacitive and Resistive Touch Screens?

Capacitive touch screens have high touch sensitivity. They can sense a very gentle tap and allow multi-touch gestures like pinch or zoom. Their clarity is better because fewer materials block the display.

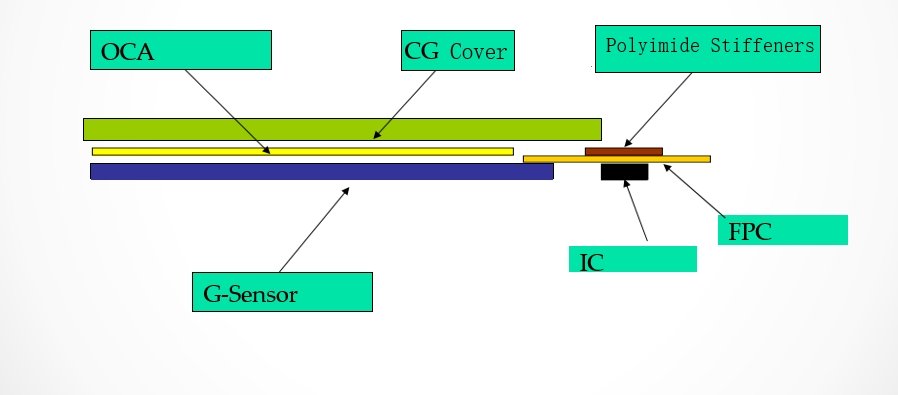

Resistive touch screens need a more forceful press to work. They only detect one touch at a time and usually look less sharp because of the extra layers((Structure of Each Layer of the Capacitive Touch Screen Cover)).

Tablet users prefer capacitive touch for multi-touch support. This feature is useful in gaming, drawing, or typing with both hands. In environments where users wear gloves, like warehouses or hospitals, resistive screens respond to any pressure, even from gloved fingers or tools. Field devices sometimes combine both types for flexibility(Self Mutual Projected Capacitive Touchscreen: What Is It?).

| Feature | Capacitive | Resistive |

|---|---|---|

| Touch Sensitivity | Light touch response | Pressure detection |

| Multi-Touch | Supported | Not supported |

| Display Clarity | High (optical transparency) | Lower (additional layers) |

| Glove/Tool Use | Limited | Works with most objects |

How Do Capacitive and Resistive Touch Screens Compare in Real-World Use?

Capacitive and resistive touch screens differ significantly in how they respond to various inputs, how fast they react, and how well they handle environmental challenges. Capacitive screens detect the electrical properties of the human body, while resistive screens respond to physical pressure from nearly any object. These differences impact where each screen type works best, how durable they are, and how much maintenance they require.

In a kiosk project used in outdoor public spaces, resistive screens were chosen due to their better resistance to dust and water, and their ability to work with non-conductive tools like gloves or plastic pens. On the other hand, a team developing a retail point-of-sale device used capacitive screens for their fast input recognition and clearer display, as employees mostly used bare fingers. The environment and user behavior should drive the choice between capacitive and resistive screens(How is Waterproof Touch Functionality Achieved in LCD Devices?).

Here is a visual comparison of their real-world performance:

| Feature | Capacitive Touch Screen | Resistive Touch Screen |

|---|---|---|

| Input Compatibility | Fingers or capacitive stylus only | Fingers, gloves, styluses, any object |

| Response Speed | Fast | Moderate |

| Touch Accuracy | High, especially for multi-touch | Good, single-touch only |

| Sensitivity to Light Touch | Excellent | Requires firm press |

| Durability (Surface Wear) | Scratch-resistant glass | Prone to surface wear over time |

| Maintenance Needs | Low | Higher due to wear and pressure stress |

| Resistance to Dust & Water | Limited unless sealed properly | Better resistance even when exposed |

| EMI Interference Tolerance | Lower | Higher |

What Are the Key Technical Differences Between Capacitive and Resistive Screens?

| Criteria | Capacitive | Resistive |

|---|---|---|

| Conductive Input Needed | Yes | No |

| Works with Gloves | Not standard (requires tuning) | Yes |

| Multi-Touch | Yes | No |

| Screen Brightness | High | Medium to Low |

What Are the Strengths and Weaknesses of Each Touch Screen Type?

Capacitive screens excel in user experience through high sensitivity, support for multi-touch gestures, and clear visuals. They are widely used in smartphones, tablets, and consumer devices. But they are more expensive, don’t work well with gloves or basic styluses, and can suffer from electromagnetic interference (EMI) in some environments.

Resistive screens are strong in practical use scenarios like ATMs, factories, and medical devices. They function with almost any tool, work well under pressure or with gloves, and are more affordable. However, they offer lower clarity, no multi-touch, and have reduced sensitivity to light touches.

To summarize real usability strengths and limits:

| Aspect | Capacitive Pros | Capacitive Cons | Resistive Pros | Resistive Cons |

|---|---|---|---|---|

| Touch Sensitivity | Very responsive | May miss input with gloves | Works under any pressure | Less responsive to light touch |

| Clarity | Bright and sharp display | May suffer from EMI | Functional in bright/dusty areas | Dimmer, less crisp image |

| Durability | Long-lasting surface | Glass may crack under impact | Flexible, low-cost layers | Wears down faster |

| Environmental Use | Indoor or retail use | Less suitable for outdoor | Outdoor, rugged use | May need replacement over time |

How Do You Choose the Right Touch Screen Technology for Your Application?

Selecting the best touch screen technology starts with the application scenario. For consumer electronics, users expect fast response and high clarity. In industrial use or outdoor settings, devices face dust, water, and glove operation. Medical environments require reliable touch through gloves and easy cleaning. Automotive applications need screens readable in sunlight and usable by drivers wearing gloves. For public-facing devices, durability against heavy use and vandalism is a priority. To match technology with needs, check user expectations, budget considerations, environmental factors, and maintenance needs.

In project planning, teams look at how touch performance changes in different settings. For example, using a capacitive screen in a factory may cause issues if gloves are needed, but a resistive screen in a modern phone can frustrate users with poor gesture control. Budget affects material choice and lifespan. Environmental factors like temperature, moisture, or sunlight impact which technology will last. Many failures come from ignoring real-world use, such as kiosks in cold climates with users wearing thick gloves.

| Scenario | Best Technology | Key Needs | Common Mistake Example |

|---|---|---|---|

| Consumer electronics | Capacitive | Fast, multi-touch, clarity | Resistive screen in a smartphone |

| Industrial use | Resistive | Glove/tool use, durability | Capacitive screen on factory line |

| Medical environments | Resistive | Glove, easy clean, reliability | Capacitive in surgical setting |

| Outdoor settings | Resistive/Hybrid | Water, sunlight, wide temp range | Capacitive in rainy ticket machines |

| Automotive | Capacitive/Hybrid | Sunlight readable, gloved input | Resistive in modern infotainment |

| Public devices | Resistive/Hybrid | Vandal-proof, any input type | Capacitive ATM in public square |

Which Touch Screen Technology Is Best for Different Application Scenarios?

Capacitive screens work best in consumer electronics like smartphones and tablets, where users want smooth multi-touch and crisp displays. For industrial use, resistive screens are ideal because they work with gloves and tools. Medical environments prefer resistive technology to support glove use and withstand frequent cleaning. In outdoor settings with rain, dust, or sunlight, a resistive or hybrid touch screen performs well. Automotive applications often combine technologies for visibility and gloved touch. Public-facing devices such as kiosks and ticketing machines rely on tough, easy-to-use screens that work with any object.

A hospital selects resistive panels for medical devices, avoiding missed touches from latex gloves. Car dashboards use capacitive glass for gestures but tune for glove sensitivity. ATMs in subways choose resistive screens to survive coins, keys, and high usage. Outdoor vending machines with only capacitive screens can stop working during rain, leading to user complaints.

Scenario Comparison Chart

| Scenario | Ideal Technology | Main Reason | Example Case |

|---|---|---|---|

| Smartphones/Tablets | Capacitive | Fast, clear, multi-touch | Mobile phone screens |

| Factories | Resistive | Works with gloves/tools | Touch panels on production lines |

| Hospitals | Resistive | Reliable through gloves, easy to clean | Medical device touch interface |

| Outdoors | Resistive/Hybrid | Survives weather, sun, temp changes | Ticket kiosks at bus stops |

| Cars | Capacitive/Hybrid | Sunlight readable, glove input | Infotainment systems in vehicles |

| Kiosks/ATMs | Resistive/Hybrid | High use, any input, vandal resistance | Ticket machines at train stations |

What Are the Key Decision Criteria and Real-World Considerations?

| Factor | Capacitive Fit | Resistive Fit |

|---|---|---|

| User Input Method | Finger or conductive stylus | Finger, glove, or any object |

| Environment Conditions | Clean, indoor | Dirty, outdoor, or wet |

| Budget Constraints | Higher cost, more features | Lower cost, simpler tech |

| Durability Needs | Durable glass, limited in rough use | Layer wear possible, but replaceable |

| Visual Quality | Sharp and bright | Lower brightness and clarity |

| Failure Risk If Misapplied | Glove input won’t register | May scratch or wear under hard use |

HUA XIAN JING not only offers ODM/OEM services for LCD modules but also provides comprehensive customization and integration services for capacitive and resistive touch screens. We are capable of meeting the specialized requirements of various industries, including touch integration for industrial HMIs, automotive infotainment screens, and medical device interfaces—ensuring reliable and efficient human-machine interaction across diverse applications.

What Are the Deep Technical Differences and Specifications of Capacitive and Resistive Touch Screens?

Capacitive and resistive touch screens are built from different glass types, ITO layers, flexible films, and circuit patterns. Each layer is designed for specific electrical characteristics. System integration demands careful selection of the controller, matching the sensor layout and signal requirements. Calibration requirements differ—resistive screens need regular tuning, while capacitive types often work automatically but may need PCAP customization.

Project teams must know each layer function. Glass types affect durability and clarity. ITO layers conduct signals for capacitive screens. Flexible films in resistive types respond to pressure. Circuit patterns set sensitivity and resolution. Microcontroller compatibility affects speed and touch response. A good design adjusts controller integration to minimize noise and optimize performance.

What Are the Material and Layer Differences in Capacitive and Resistive Touch Screens?

Capacitive screens use hardened glass and thin, transparent ITO layers. The circuit pattern is etched on ITO, creating a grid that senses changes in the electric field.

Resistive screens stack two flexible films or glass, both coated with a conductive layer. Pressing the top film bends it to touch the lower layer, closing the circuit.

- Capacitive:

- Glass types: Hardened, chemically strengthened

- ITO layers: Thin, transparent, top and bottom surfaces

- Circuit patterns: Grid of sensing electrodes

- Resistive:

- Flexible films: Polyethylene terephthalate (PET) or glass

- Conductive coating: ITO or similar

- Spacer dots: Keep layers apart until pressed

- Circuit pattern: Simple lines for X/Y position detection

| Layer/Component | Capacitive Touch Screen | Resistive Touch Screen |

|---|---|---|

| Glass types | Hardened, optical, thin | Flexible, sometimes glass |

| ITO layers | Transparent, on both surfaces | On flexible film or glass |

| Flexible films | Not used (in classic designs) | Main input layer |

| Circuit patterns | Fine grid, multi-touch | Simple lines, single-touch |

| Spacer dots | Not used | Yes |

| Layer thickness | Thin, for optical clarity | Thicker, may reduce clarity |

How Are Touch Screens Integrated and Customized in System Design?

System integration starts with matching the touch panel’s electrical characteristics to the microcontroller. PCAP customization (projected capacitive) may be needed for glove support, water rejection, or custom shapes. Resistive screens require calibration for precise position mapping. This can be manual or software-based.

Capacitive Touch Screens

- Integration: Works with microcontrollers supporting PCAP (Projected Capacitive) technology. This enables multi-touch and gesture recognition.

- Customization: Offers flexibility like adjusting touch sensitivity or adding protective layers. Common in high-end devices.

- Calibration: Minimal tuning needed due to the electrostatic field design.

Resistive Touch Screens

- Integration: Uses simpler controllers that detect pressure. No need for advanced PCAP support.

- Customization: Limited but practical for specific uses, like glove compatibility in industrial settings.

- Calibration: Requires precise tuning to ensure accurate touch detection, as pressure sensitivity varies.

| Feature | Capacitive | Resistive |

|---|---|---|

| Integration | PCAP, microcontrollers | Simple controllers |

| Customization | High (gestures, sensitivity) | Basic (touch functions) |

| Calibration | Minimal | Precise tuning needed |

Related Articles:

What Are the Differences Between Built-In and External LCD Controllers?

Are all common character LCD modules based on the Hitachi HD44780 controller?

What Is Color Inversion in LCD Displays?

How Do LCD Modules Withstand Salt-Fog Environments?

What Is a Frame Buffer and How Does It Work in Embedded Systems?

FAQ

Can resistive screens handle multi-touch gestures?

No, most resistive screens are designed for single-point input and do not support multi-touch gestures

Do Capacitive screens use more power than resistive screens?

Capacitive screens consume slightly more power due to continuous electrostatic field monitoring. Resistive screens use power only when pressure activates the circuit.

Can capacitive screens work with wet fingers?

Capacitive screens struggle with wet fingers, as moisture disrupts electrostatic fields. Resistive screens handle wet conditions better with pressure-based input.

How long do capacitive and resistive screens last?

Capacitive screens last longer with glass substrates, but scratches reduce lifespan. Resistive screens wear faster due to flexible film pressure.

Is software integration easier for capacitive screens?

Capacitive screens integrate easily with PCAP controllers for multi-touch support. Resistive screens need complex tuning for pressure sensitivity.