Multiplexing in LCDs reduces pin count to simplify hardware design. It lowers manufacturing costs for small and medium size LCDs. This technique enables compact displays in devices like calculators and IoT modules. Engineers use multiplex drive to balance cost and display performance. However, contrast and flicker challenges may arise in high-resolution applications. Multiplexing suits embedded LCD systems where space and budget are priorities.

What is Multiplexing in LCDs?

Multiplexing in LCDs is a technique that cuts down the number of pins needed to control the display by grouping segments and activating them one by one. It works by organizing the display into rows and columns, turning on one row at a time while sending signals to the columns.

This method is a go-to choice for small and medium size LCDs because it keeps the hardware simple and cheap. Designers often use it in embedded LCD systems where space is tight, but they must watch out for dimmer visuals as a trade-off.

Technical Details of Multiplexing in LCDs

- Multiplex Ratio: This shows how many rows share one set of column drivers. A 4:1 ratio means four rows run off one set.

- Duty Cycle: Each row gets power for a fraction of the time. With a 4:1 ratio, a row is on for 1/4 of the cycle.

- Voltage Control: The system uses exact voltages to light up the right segments. This is handled by a multiplex drive setup.

- Frame Rate: The display refreshes at 60 Hz or more to stop flickering.

| Feature | Details |

|---|---|

| Multiplex Ratio | Number of rows tied to one column driver set. |

| Duty Cycle | Time each row is active during a cycle. |

| Voltage Control | Exact levels to turn on specific segments. |

| Frame Rate | Speed of refresh, usually 60 Hz or higher, to avoid flicker. |

How Does Multiplexing Affect LCD Performance?

Multiplexing affects LCD performance by changing contrast and speed based on how many rows are grouped. It makes displays affordable but can lower quality if not balanced right.

This trade-off matters in graphic LCDs where clear visuals are key. Designers tweak the multiplex ratio to keep the display sharp and responsive for users.

Key Factors in Performance

- Contrast Drop: More rows in the multiplex definition can make visuals less bold. A lower ratio helps keep them crisp.

- Speed Impact: Higher multiplexing needs faster updates. A quick multiplex drive ensures smooth changes on screen.

- Power Use: The setup can shift energy needs. Smart voltage tweaks cut down on waste.

How Multiplexing Works in LCDs?

Multiplexing in LCDs operates by organizing display segments into rows and columns, which are activated in a time-shared sequence rather than all at once. This approach reduces the number of pins required to control the display, making it an efficient solution for compact and cost-effective designs. By sharing connections among multiple segments, multiplexing simplifies the hardware while still enabling a functional display.

Row and Column Addressing

In a multiplexed LCD, segments are controlled by applying voltage at the intersections of rows and columns. Timing signals dictate when each intersection is activated, illuminating the corresponding segment. This method, known as addressing, ensures that only the intended segments light up at the right time, creating a coherent display.

Multiplex Ratios

Multiplex ratios, such as 1:2 or 1:4, define how many segments share a single pin. For example:

- 1:2: Two segments share one pin.

- 1:4: Four segments share one pin.

A higher ratio reduces the pin count, which saves space and cost, but it can also lower the display’s brightness or contrast if not managed properly. This balance is critical in determining the overall quality of the LCD.

Driver Role

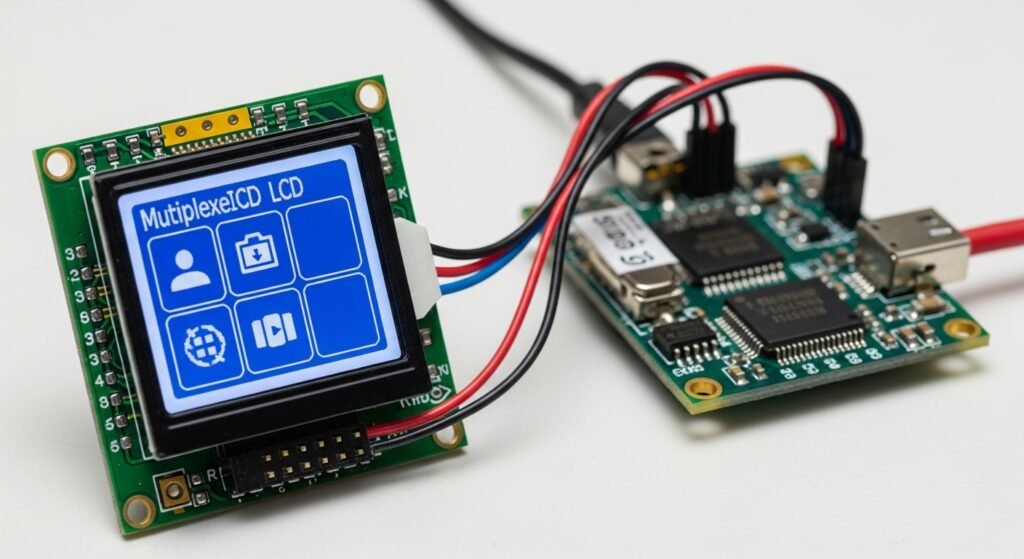

A microcontroller or integrated circuit (IC) serves as the driver in a multiplexed LCD system. It sends precisely timed signals to control the sequence of segment activation. This process, often referred to as the multiplex drive, ensures that the display updates smoothly without flickering or errors.

Static vs. Dynamic Multiplexing

The choice between static and dynamic multiplexing depends on the display’s size, complexity, and the available space for hardware connections.

Multiplexing in LCDs can be categorized into two types:

- Static (Direct Drive): Each segment has its own dedicated pin. This method is simple to implement but requires more pins, making it less practical for complex displays.

- Dynamic (Multiplexed): Multiple segments share pins, activated in a timed sequence. This reduces the pin count but demands precise timing control to maintain display clarity.

Benefits of Multiplexing in LCDs

Multiplexing in LCDs is a clever technique that allows multiple signals to share a single connection, much like a telephone exchange routing several calls through a few lines. In the context of liquid crystal displays (LCDs), this means controlling numerous display segments with fewer pins. Let’s explore the key benefits this approach brings to LCD design and functionality.

Reduced Pin Count

One of the standout advantages of multiplexing is the reduction in pin count. By allowing multiple segments to share the same pin, multiplexing drastically cuts down the number of external connections required. For example, in a 1:4 multiplexed setup, four segments can be controlled with just one pin instead of four. This simplifies hardware design, making it especially valuable for compact devices like digital watches or calculators, where space is at a premium.Simplified Drive Circuitry

Multiplexing also streamlines the electronics that power the display, known as the drive circuitry. With fewer pins to manage, the complexity of signal management decreases significantly. This means designers can create less intricate circuits, reducing the time and effort needed for development. Think of it as organizing a busy office with fewer phone lines—less clutter, easier coordination, and a smoother operation overall.Increased Display Density

Another benefit is the ability to pack more segments into a limited space, boosting display density. This is particularly useful for small and medium-sized LCDs or graphic LCDs, where maximizing information in a compact area is crucial. Multiplexing enables devices like smartwatches or medical monitors to show detailed data—such as time, notifications, or vital signs—without requiring a larger physical footprint. It’s like fitting more passengers into a single bus without adding extra seats.Cost Efficiency

Finally, multiplexing drives down manufacturing costs. The reduced pin count and simplified drive circuitry mean fewer materials and less complex assembly processes. For instance, a multiplexed LCD might save up to 75% of the pins compared to a static drive, lowering production expenses. This cost efficiency makes multiplexing a go-to choice for affordable consumer electronics, from smartphones to car dashboards, ensuring high performance doesn’t come with a high price tag.

Challenges of Multiplexing in LCDs

Multiplexing in LCDs is a technique where multiple segments share the same control pins, activating them in a time-shared sequence rather than all at once. While this reduces the number of connections needed, it introduces several challenges that impact display quality and performance. Below, we explore these challenges—reduced contrast, flicker and refresh rate issues, and scalability limits—and discuss potential mitigations.

Reduced Contrast

In a multiplexed LCD, segments are not continuously active. Instead, they are turned on only part of the time in a shared cycle, which reduces their overall brightness and contrast. Multiplexing means that the display controller rapidly switches between segments, illuminating each one briefly. The more segments sharing the same pins (a higher multiplex ratio), the less time each segment is active, making the display appear dimmer compared to a non-multiplexed setup.

Mitigation Strategies

- Higher Refresh Rates: By increasing how often the segments are cycled, brightness can be better maintained, though this requires more power and faster electronics.

- Better LCD Materials: Using advanced materials like STN (Super-Twisted Nematic) can enhance contrast over basic TN (Twisted Nematic) LCDs. However, costlier options like IPS TFT (In-Plane Switching Thin-Film Transistor) are typically avoided in budget-conscious designs due to their higher price.

Flicker and Refresh Rate

A higher multiplex ratio can lead to flicker, where the display appears to blink. This happens because each segment’s active time becomes shorter as more segments are multiplexed, and if the refresh rate—the speed at which the display cycles through all segments—isn’t fast enough, the human eye notices the interruptions. Multiplexing, in this context, refers to the process of managing multiple display elements with fewer control lines, but it demands precise timing.

Optimization Techniques

- Optimized Timing: Fine-tuning the signal timing ensures segments refresh quickly enough to appear steady, reducing flicker.

- Higher Refresh Rates: Boosting the refresh rate helps, but it increases power consumption and the complexity of the driving circuitry, requiring a careful trade-off.

Scalability Limits

Multiplexing works well for small to medium-sized displays, like those in simple calculators or embedded LCD systems (e.g., in appliances or small gadgets). However, it becomes less effective for large or high-resolution displays. As the number of segments grows, each segment’s active time shrinks further, worsening contrast and flicker. Additionally, the control circuitry becomes more complex, making it harder to maintain quality across a bigger screen.

Why Scalability is Limited

- Reduced Active Time: More segments mean less time per segment, degrading visibility.

- Circuit Complexity: Larger displays require intricate timing and more robust drivers, increasing design difficulty.

- Alternative Approaches: For bigger or sharper displays, technologies like active matrix TFT are often used instead, despite their higher cost.

What Are the Practical Applications of Multiplexing in LCDs?

- Small Devices: Multiplexing shines in small and medium size LCDs, such as those in calculators, watches, and thermometers. A 1:4 multiplex ratio often controls multiple segments with minimal pins.

- Embedded Systems: In embedded LCD systems, multiplexing supports microcontroller-driven displays in IoT devices, using 8-bit microcontrollers for efficient signal timing.

- Power Efficiency: Multiplexed displays consume less than 1 mA/cm² in low-power setups, extending battery life in portable devices.

- Refresh Rates: A 60 Hz refresh rate ensures smooth visuals in most LCD modules.

| Application | Details |

|---|---|

| Small Devices | Calculators, watches, thermometers use 1:4 ratios for compact designs. |

| Embedded Systems | IoT devices rely on multiplex drive with 8-bit controllers. |

| Power Efficiency | Consumes <1 mA/cm², ideal for battery-powered LCD modules. |

| Refresh Rates | 60 Hz or higher prevents flicker in small and medium size LCDs. |

Why Is Multiplexing Less Suited for High-Quality Displays?

Multiplexing is less effective for high-quality displays like IPS TFT LCDs due to contrast and scalability issues. It struggles to meet the demands of large, high-resolution screens requiring vibrant visuals.

This limitation pushes designers toward active matrix technologies for premium displays. For users needing sharp, colorful outputs, multiplexing may fall short, raising concerns about visual quality.

Limitations in High-Quality Displays

- Contrast Reduction: Higher multiplex ratios (e.g., 1:8) reduce segment active time, dimming graphic LCDs.

- Scalability Issues: Large displays need complex multiplex drives, increasing flicker risk at <50 Hz.

- Alternative Technologies: IPS TFT LCDs use active matrix drivers for better clarity but at higher costs.

How Do Multiplexed and Direct-Drive LCDs Compare?

Multiplexed LCDs share pins across multiple segments, while direct-drive LCDs use one pin per segment for maximum clarity. Multiplexing saves space and cost, but direct-drive offers superior contrast for specific applications.

Designers pick multiplexing for compact, low-cost devices like calculators, where small and medium size LCDs thrive. Direct-drive suits applications needing crisp visuals, despite higher pin counts, guiding choices in embedded LCD systems.

- Pin Count: Multiplexed LCDs use fewer pins (e.g., 1:4 ratio controls four segments per pin), while direct-drive needs one pin per segment.

- Cost: Multiplexing reduces hardware costs by up to 70% compared to direct-drive in LCD modules.

- Contrast: Direct-drive achieves 100% segment active time, ensuring sharper visuals than multiplexed displays.

- Power: Multiplexed systems consume <1 mA/cm², while direct-drive may use 2-3 mA/cm² due to more active pins.

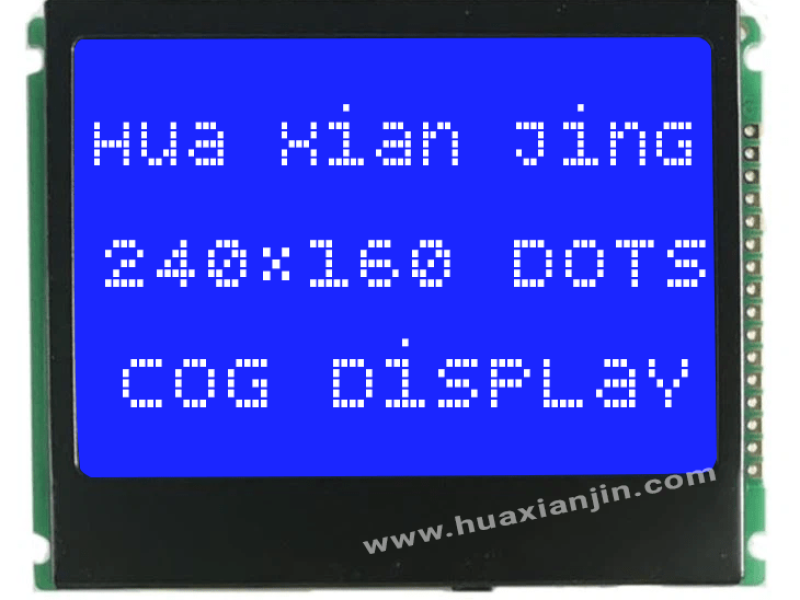

- Scalability: Multiplexing supports graphic LCDs up to 240×128 pixels, but direct-drive struggles beyond 100 segments.

| Feature | Multiplexed LCD | Direct-Drive LCD |

|---|---|---|

| Pin Count | Low (e.g., 1:4 ratio, 4 segments/pin) | High (1 pin per segment) |

| Cost | Lower (up to 70% savings) | Higher (more pins, complex circuits) |

| Contrast | Moderate (reduced by time-sharing) | High (100% active time) |

| Power | <1 mA/cm² in low-power setups | 2-3 mA/cm² |

| Scalability | Good for 240×128 pixels max | Limited to ~100 segments |

When Should You Choose Multiplexed or Direct-Drive LCDs?

Multiplexed LCDs suit compact, battery-powered devices, while direct-drive LCDs are ideal for high-contrast, small-scale displays. Multiplexing fits cost-sensitive applications, but direct-drive excels in clarity-critical uses.

This choice addresses user needs for cost, power, and visual quality. For high-resolution or fast-refresh displays, multiplexing may disappoint, prompting users to consider direct-drive or active matrix alternatives.

Use-Case Suitability

- Multiplexed LCDs: Best for calculators, watches, and embedded LCD systems with 1:2 or 1:4 ratios. They save pin count and power, ideal for battery-powered devices.

- Direct-Drive LCDs: Preferred for small graphic LCDs needing maximum contrast, like medical readouts, but limited to fewer segments.

- Avoid Multiplexing: Not suitable for IPS TFT LCDs or displays requiring >60 Hz refresh rates due to flicker risks.

What Are the Key Differences Between Multiplexing and Direct Drive in LCDs?

Multiplexing shares pins among segments to save space, while direct drive uses one pin per segment for top contrast. Multiplexing cuts costs and complexity, but direct drive delivers sharper visuals.

Designers favor multiplexing for small and medium size LCDs in cost-sensitive devices like thermometers. Direct drive fits applications needing high clarity, such as medical displays, despite increased pin requirements.

- Pin Count: Multiplexing uses 1:4 or 1:8 ratios, controlling multiple segments per pin. Direct drive requires one pin per segment.

- Cost: Multiplexed LCD modules reduce hardware costs by up to 65% compared to direct drive.

- Contrast Quality: Direct drive ensures 100% active time per segment, while multiplexing lowers brightness due to time-sharing.

- Power Consumption: Multiplexed displays use <0.8 mA/cm², while direct drive consumes 1.5-2.5 mA/cm².

- Complexity: Multiplexing simplifies multiplex drive circuits; direct drive needs more intricate wiring.

| Feature | Multiplexing | Direct Drive |

|---|---|---|

| Pin Count | Low (1:4 or 1:8 ratios) | High (1 pin/segment) |

| Cost | 65% lower than direct drive | Higher (more pins) |

| Contrast | Moderate (time-shared) | High (100% active time) |

| Power | <0.8 mA/cm² | 1.5-2.5 mA/cm² |

| Complexity | Simpler multiplex drive | More complex wiring |

When Should You Choose Multiplexing Over Direct Drive?

Multiplexing is ideal for cost-sensitive, compact designs like calculators or IoT devices. Direct drive suits high-contrast needs but is less practical for complex displays.

This choice addresses user concerns about balancing cost and quality. Multiplexing may not meet demands for IPS TFT LCDs or fast-refresh applications, pushing designers toward direct drive for premium visuals.

Use-Case Considerations

- Multiplexing: Best for embedded LCD systems in battery-powered devices with 1:4 ratios.

- Direct Drive: Suited for small graphic LCDs needing maximum contrast, like instrumentation panels.

- Avoid Multiplexing: Not ideal for high-resolution displays or refresh rates above 60 Hz due to flicker risks.

FAQ

How does temperature affect multiplexed LCD performance?

Temperature extremes can slow LCD response times or reduce contrast in multiplexed displays. Using temperature-compensated drivers or materials like STN LCDs helps maintain performance across varying conditions.

What happens if the multiplex driver fails in an LCD?

A failed multiplex driver can cause the entire display to stop functioning or show erratic patterns. Replacing the driver IC or checking for signal integrity issues typically resolves this problem.

Can multiplexing support color LCDs effectively?

Multiplexing is less effective for color LCDs due to the need for precise control over multiple color layers, often leading to poor color accuracy. Active matrix technologies like TFT are better suited for color displays.

How do you choose the right multiplex ratio for a project?

The right multiplex ratio depends on balancing pin count, contrast needs, and refresh rate capabilities for your specific display size. Start with a lower ratio (e.g., 1:2 or 1:4) and adjust based on testing for optimal clarity.

What microcontrollers support multiplexed LCD driving?

Most MCUs with general-purpose I/O and timer modules can drive multiplexed LCDs. Look for controllers with waveform generator peripherals for ease.