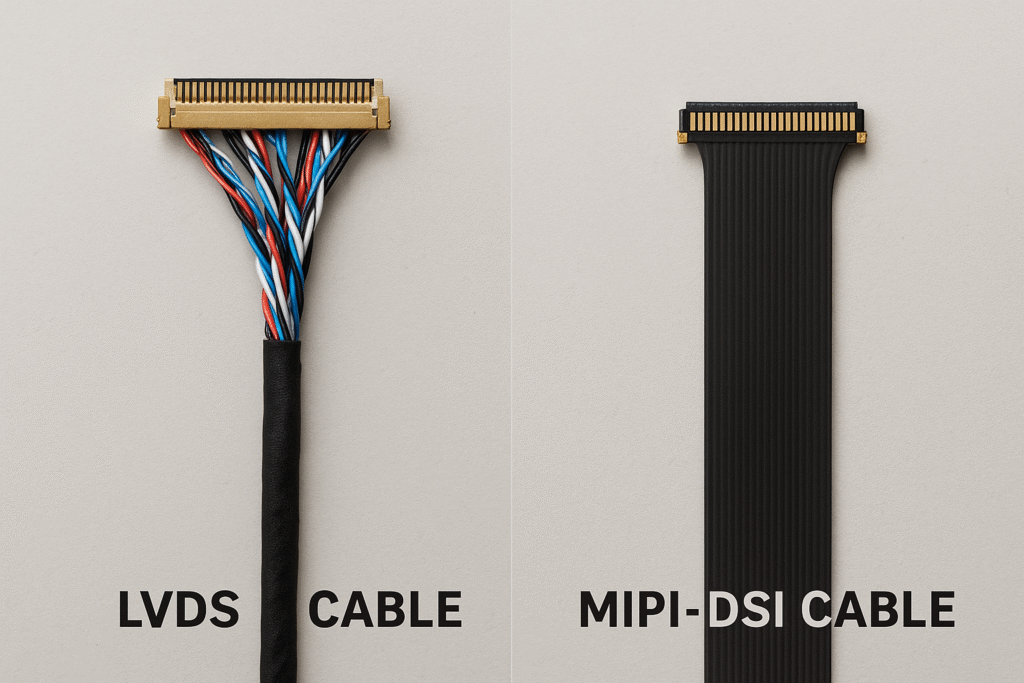

LVDS and MIPI DSI differ in signaling, speed, and applications. LVDS uses differential pairs for stable, high-speed data. MIPI DSI offers flexibility for modern displays with lower pin counts.

Years ago, I faced a tough choice between these interfaces for a client’s project. That experience taught me their strengths and weaknesses. Let’s dive into the details.

How Do LVDS Electrical and Signaling Characteristics Work?

Understanding LVDS starts with its core design. It’s a reliable, high-speed interface I’ve used in many LCD projects. Let’s explore its electrical and signaling traits.

LVDS uses differential signaling with low-voltage pairs. It operates at 1.8V to 3.3V, delivering data rates up to 3.125 Gbps. It ensures noise immunity and long-distance transmission.

How LVDS Works

LVDS, or Low Voltage Differential Signaling, relies on differential pairs to transmit data. Each pair consists of two wires carrying opposite signals. This setup cancels noise, making it ideal for high-speed applications. In my experience, LVDS shines in industrial displays where reliability is key.

1. Voltage and Power Efficiency

LVDS operates at low voltages, typically 1.8V to 3.3V. This reduces power consumption compared to older TTL interfaces. For example, a 24-bit RGB display running at 1080p needs stable, low-power signaling, which LVDS provides(Detailed Explanation of TTL Signal and LVDS Signal in LCD).

2. Data Rates and Bandwidth

LVDS supports data rates up to 3.125 Gbps per lane. In a typical 4-lane setup, it handles high-resolution displays like 1920×1080 at 60 Hz. I’ve seen clients use LVDS for large panels where bandwidth matters.

3. Noise Immunity

Differential signaling gives LVDS strong noise resistance. The paired signals cancel electromagnetic interference (EMI), ensuring clean data transmission over long cables, often up to 10 meters. This is why I recommend LVDS for rugged environments.

| Feature | LVDS Characteristics |

|---|---|

| Voltage Range | 1.8V–3.3V |

| Max Data Rate | 3.125 Gbps per lane |

| Noise Immunity | High (differential signaling) |

| Typical Cable Length | Up to 10 meters |

What Are the MIPI DSI Protocol and D-PHY Layer?

MIPI DSI is newer and built for modern displays. I’ve implemented it in compact devices. Let’s break down its protocol and D-PHY layer.

MIPI DSI uses a packet-based protocol with D-PHY for high-speed data. It supports up to 4 Gbps per lane, ideal for mobile and compact displays with low pin counts.

Understanding MIPI DSI

MIPI DSI, or Display Serial Interface, is a packet-based protocol designed for efficiency. Its D-PHY layer handles both high-speed (HS) and low-speed (LP) signaling. I’ve used it for smartphone and tablet displays due to its flexibility.

1. D-PHY Structure

D-PHY uses one clock lane and up to four data lanes. HS mode transmits data at up to 4 Gbps per lane, while LP mode handles initialization and control. This dual-mode approach saves power, which I’ve seen benefit battery-powered devices(HDMI vs. MIPI-DSI: Which Display Interface Is Right for You?).

2. Packet-Based Communication

MIPI DSI sends data in packets, including headers and error-checking. This reduces errors in complex displays. For a 4K display, MIPI DSI’s packet structure ensures reliable data delivery.

3. Scalability

MIPI DSI scales from small screens to 4K panels. I’ve worked with clients who chose MIPI for its ability to handle high resolutions with fewer lanes than LVDS.

| Feature | MIPI DSI Characteristics |

|---|---|

| Data Rate per Lane | Up to 4 Gbps |

| Lane Configuration | 1 clock + 1–4 data lanes |

| Signaling Modes | High-Speed (HS) and Low-Speed (LP) |

| Typical Use | Mobile, tablet, and compact displays |

Which Interface Has Better Signal Integrity, LVDS or MIPI DSI?

Signal integrity is critical for display performance. I’ve seen projects fail due to poor signaling. How do LVDS and MIPI DSI compare?

Firmware setup for MIPI DSI can be tricky. I’ve spent hours debugging initialization. What’s the best approach to get it right?

Initialize MIPI DSI by configuring D-PHY, setting packet parameters, and enabling HS mode. Use vendor-specific commands for display compatibility. Timing is critical for stability(How do timing controllers (TCON) synchronize image data in LCDs?).

LVDS offers superior noise immunity for long cables. MIPI DSI excels in short-range, high-speed applications with lower power. Both handle high resolutions, but cable length matters.

Comparing Signal Integrity

Signal integrity affects display quality and reliability. LVDS and MIPI DSI approach this differently, and I’ve seen both in action across various projects.

1. LVDS Noise Resistance

LVDS’s differential signaling reduces EMI, making it ideal for long cables. In one project, a 5-meter cable caused no issues with LVDS, but MIPI struggled beyond 1 meter.

2. MIPI DSI’s Short-Range Advantage

MIPI DSI’s high-speed mode is optimized for short distances, typically under 1 meter. Its compact design suits mobile devices, but long cables degrade signal quality.

3. Error Handling

MIPI DSI’s packet-based system includes error-checking, reducing data corruption. LVDS lacks this but compensates with robust signaling. I’ve found MIPI better for dense, high-resolution displays.

| Parameter | LVDS | MIPI DSI |

|---|---|---|

| Cable Length | Up to 10m | Up to 1m |

| Noise Immunity | High | Moderate |

| Error Correction | None | Packet-based |

How Do Pinouts and PCB Design Differ for LVDS and MIPI DSI?

Proper implementation ensures display success. I’ve designed PCBs for both interfaces. What are the key considerations for pinouts and PCB layout?

LVDS requires more pins (20–30) for high resolutions. MIPI DSI uses fewer (8–12) with simpler PCB routing. Both need careful impedance control for reliable performance.

Designing for LVDS and MIPI

PCB design impacts cost and performance. I’ve learned this from countless LCD module projects, and the differences between LVDS and MIPI are stark.

2. LVDS Pinouts and Routing

LVDS uses multiple differential pairs, often 4–5 data pairs plus a clock pair. This increases pin count and PCB complexity. I’ve designed boards with matched-length traces to maintain signal integrity.

3. MIPI DSI Pin Efficiency

MIPI DSI needs fewer pins, typically 1 clock and 1–4 data lanes. This simplifies PCB layout, reducing costs. I’ve used it for compact devices where space is tight.

4. Impedance and Shielding

Both interfaces require controlled impedance (100 ohms for LVDS, 50 ohms for MIPI). Proper shielding prevents crosstalk. I always recommend ground planes for both.

| Interface | Pin Count (24-bit RGB) | PCB Complexity | Impedance |

|---|---|---|---|

| LVDS | 20–30 | High | 100 ohms |

| MIPI DSI | 8–12 | Low | 50 ohms |

How Do You Initialize a MIPI DSI Display in Firmware?

Firmware setup for MIPI DSI can be tricky. I’ve spent hours debugging initialization. What’s the best approach to get it right?

Initialize MIPI DSI by configuring D-PHY, setting packet parameters, and enabling HS mode. Use vendor-specific commands for display compatibility. Timing is critical for stability.

MIPI DSI Initialization Steps

Firmware development for MIPI DSI requires precision. I’ve worked on projects where improper setup caused flickering or blank screens. Here’s how to do it right.

2. D-PHY Configuration

Start with the D-PHY layer. Set the clock lane to LP mode, then transition to HS mode. I’ve found that incorrect timing here causes most failures.

3. Packet Setup

Configure packet headers, including resolution and refresh rate. Vendor datasheets are key. For example, a 1080p display needs precise packet timing to avoid artifacts.

4. Display Commands

Send vendor-specific commands to initialize the display panel. I once debugged a project where missing commands caused a blank screen. Always verify with the datasheet.

| Step | Action |

|---|---|

| D-PHY Setup | Configure clock and data lanes |

| Packet Parameters | Set resolution, refresh rate |

| Display Commands | Send vendor-specific initialization |

When Should You Use LVDS vs MIPI DSI?

Choosing between LVDS and MIPI depends on the application. I’ve seen both excel in different scenarios. Which is better for your project?

LVDS suits large, industrial displays with long cables. MIPI DSI excels in compact, high-resolution mobile devices with low power and fewer pins.

Applications and Trade-offs

Application fit drives interface choice. I’ve advised clients on this based on their project needs, from industrial panels to smartphone displays.

1. LVDS in Industrial Settings

LVDS handles high resolutions over long distances, perfect for factory displays or medical equipment. Its high pin count is a trade-off for reliability.

2. MIPI DSI in Mobile Devices

MIPI DSI’s low pin count and power efficiency make it ideal for smartphones and tablets. I’ve seen it used in 4K displays with minimal power draw.

3. Bandwidth and Resolution

Both support high resolutions, but MIPI DSI scales better for 4K and beyond. LVDS is limited by lane count in ultra-high-resolution setups.

| Application | LVDS Fit | MIPI DSI Fit |

|---|---|---|

| Industrial Displays | Excellent | Poor |

| Mobile Devices | Poor | Excellent |

| Max Resolution | 1080p–2K | Up to 4K+ |

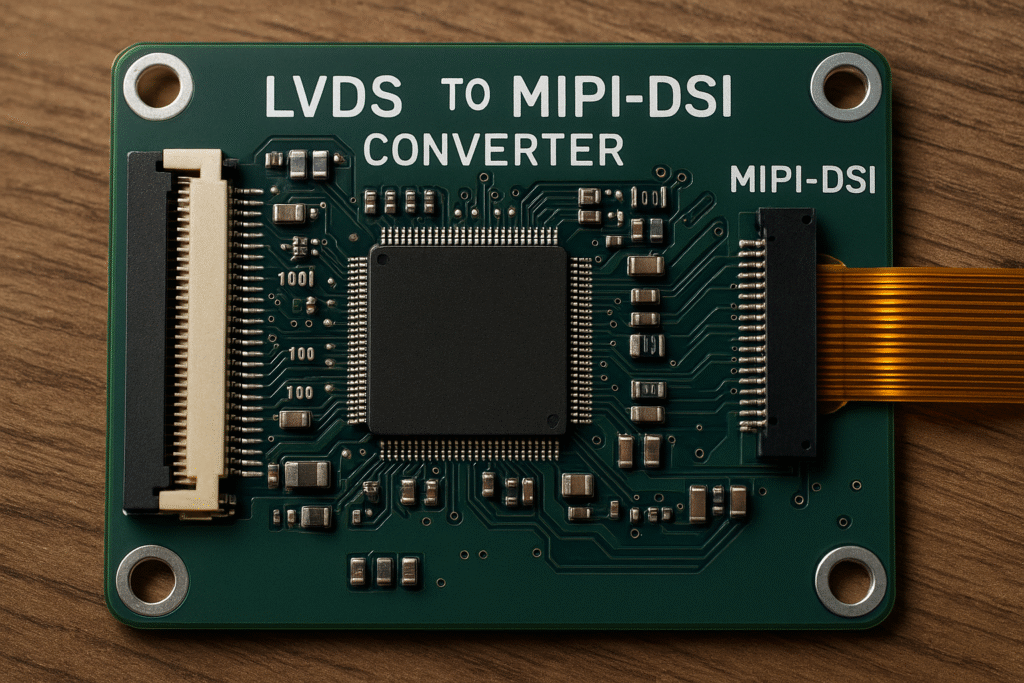

How Can You Connect an LVDS Processor to a MIPI Display?

Switching between LVDS and MIPI can be challenging. I’ve helped clients migrate systems. What are the best bridging solutions?

Use bridge ICs like SN65DSI86 for LVDS-to-MIPI or LT8912B for MIPI-to-LVDS. They simplify transitions but require careful firmware and PCB design.

Bridging LVDS and MIPI

Migration often occurs when upgrading legacy systems. I’ve implemented bridge solutions to save costs and time.

1. Bridge ICs

Chips like SN65DSI86 convert MIPI to LVDS, while LT8912B does the reverse. I’ve used these to connect modern controllers to older displays.

2. Firmware Challenges

Bridge ICs need specific firmware configurations. I once spent days debugging a bridge chip due to mismatched timing settings. Always check compatibility.

3. Cost and Complexity

Bridging adds cost but avoids redesigning entire systems. For small runs, it’s cost-effective. I recommend evaluating production volume before deciding.

| Bridge Direction | Common ICs | Key Consideration |

|---|---|---|

| MIPI to LVDS | LT8912B | Timing configuration |

| LVDS to MIPI | SN65DSI86 | Firmware setup |

How Do You Ensure EMC Compliance for LVDS and MIPI in Tough Environments?

EMC compliance is vital for automotive and industrial displays. I’ve navigated these standards for clients. How do LVDS and MIPI compare?(What EMI/EMC Rules Must Automotive LCD Displays Follow?)

LVDS has better EMC performance for long cables. MIPI DSI requires shielding for compliance. Both meet automotive and industrial standards with proper design.

Ensuring EMC Compliance

Electromagnetic compatibility (EMC) ensures displays work without interference. I’ve designed systems to meet strict automotive and industrial standards.

1. LVDS EMC Advantages

LVDS’s differential signaling reduces EMI, making it easier to pass EMC tests. I’ve used it in automotive dashboards with minimal shielding.

2. MIPI DSI Challenges

MIPI DSI’s high-speed signals generate more EMI, requiring robust shielding. I’ve added ground planes and ferrites to pass compliance tests.

3. Testing Standards

Both interfaces must meet standards like CISPR 25 for automotive. I recommend early EMI testing to avoid costly redesigns.

| Interface | EMI Performance | Shielding Needs |

|---|---|---|

| LVDS | Low EMI | Minimal |

| MIPI DSI | Higher EMI | High (ground planes) |

Conclusion

LVDS and MIPI DSI serve distinct needs. LVDS excels in industrial settings, MIPI in mobile. Choose based on application, cable length, and EMC requirements.

FAQs

What is the main difference between LVDS and MIPI DSI?

LVDS offers simple, robust differential signaling suitable for longer distances, while MIPI DSI is optimized for high-speed, low-power mobile displays with a packet-based protocol.

Can LVDS be used for high-resolution displays?

Yes, LVDS reliably supports resolutions up to Full HD/WUXGA, making it suitable for many large-screen and industrial applications.

Why is MIPI DSI preferred in mobile devices?

MIPI DSI is preferred for its low power consumption, high-resolution support, minimal pin count, and compact implementation, ideal for battery-powered devices.

How difficult is it to transition from LVDS to MIPI?

Transitioning typically requires bridge ICs or significant design changes, making it feasible but dependent on application requirements, available resources, and development timeline.

What are key EMC considerations for LVDS and MIPI DSI?

LVDS needs shielded cables to reduce EMI. MIPI DSI requires short traces and ground planes to minimize high-speed signal interference.