I’ve been working with LCD modules for over 13 years, and I can confidently say that we’re witnessing the most significant transformation in automotive instrument clusters since the invention of the dashboard itself.

LCDs are fundamentally changing how drivers interact with their vehicles by replacing traditional analog gauges with customizable, information-rich digital displays that can adapt to individual preferences and driving conditions.

Last week, I received a call from one of my longtime customers, who assembles automotive displays. He was amazed by how much his automotive clients were demanding LCD-based instrument clusters instead of the old mechanical gauges. This conversation got me thinking about just how revolutionary this shift really is.

What Technological Advancements Are Driving LCD Instrument Cluster Innovation?

Modern LCD technology has reached a maturity level that makes it perfect for automotive applications.

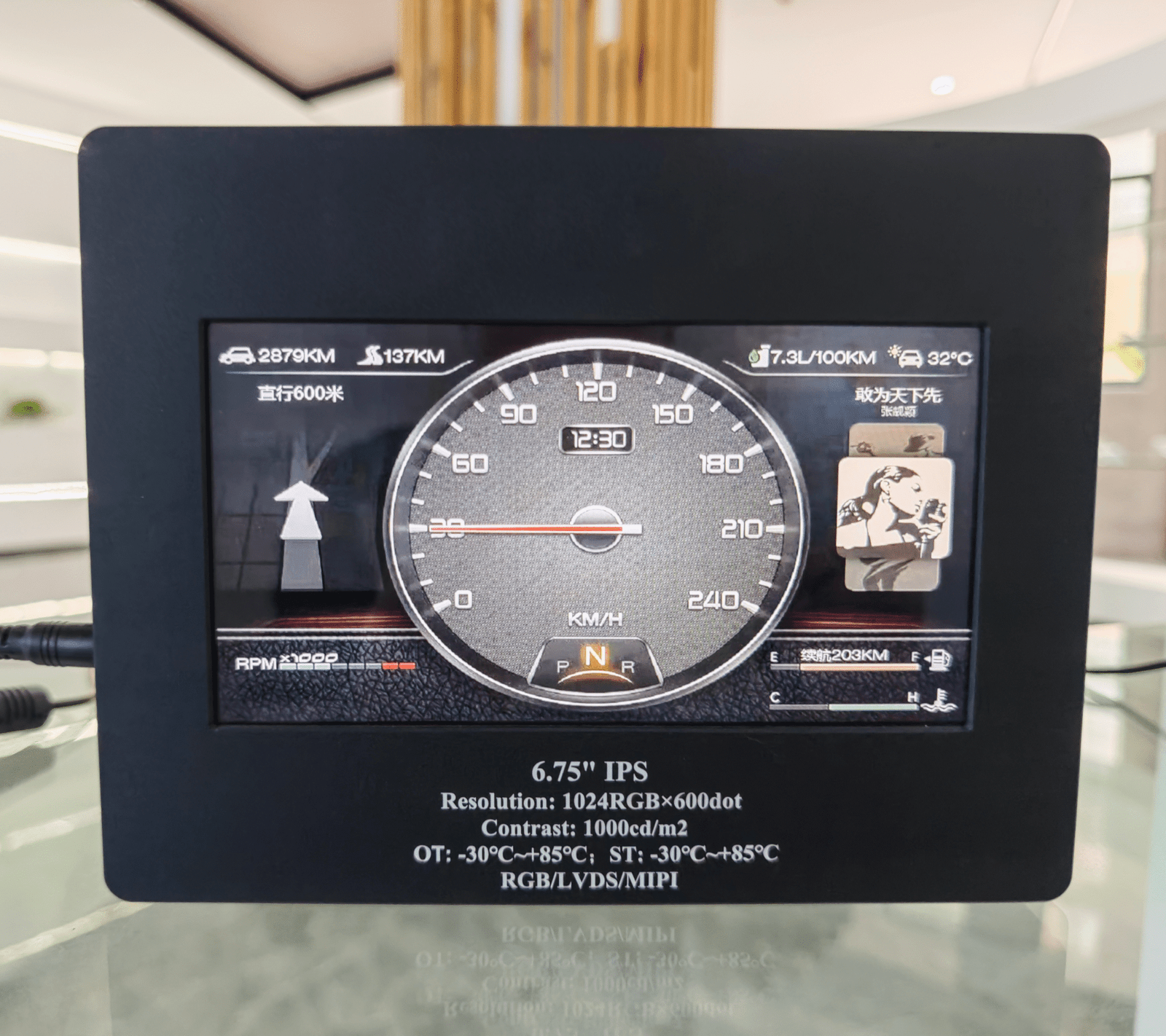

Advanced TFT-LCD displays now offer resolutions up to 1920×720 pixels, brightness levels exceeding 1000 nits for sunlight readability, and response times fast enough to eliminate motion blur during rapid data updates(What Makes an LCD Sunlight Readable??).

Display Resolution and Quality Improvements

The technological leap in LCD displays has been remarkable. Today’s automotive LCDs feature high-definition resolutions that can display detailed graphics, maps, and multiple information streams simultaneously. The improvement in display resolution has been one of the key technological innovations, with early displays offering basic monochromatic readouts evolving to full-color, high-resolution panels capable of displaying complex 3D graphics and animations(How much does the resolution of the LCD screen affect the image quality?).

Enhanced Brightness and Visibility

Automotive LCD displays now achieve brightness levels between 1000+ nits, making them highly visible even in direct sunlight. This represents a significant advancement over earlier displays that struggled with outdoor visibility. The enhanced brightness ensures that critical driving information remains clearly visible under all lighting conditions, from bright daylight to nighttime driving(Why Do LCDs Need 1,500 Nits Peak Brightness for HDR?).

Integration of Advanced Technologies

Modern LCD instrument clusters integrate seamlessly with vehicle systems through various interfaces including CAN bus, LVDS, and digital I/O connections. This integration allows for real-time data processing and display of information from multiple vehicle systems simultaneously. The displays can now show everything from basic speedometer readings to complex ADAS alerts, navigation information, and multimedia content(How is CAN or LIN Bus Integration Handled with LCD Modules?).

Processing Power and Graphics Capabilities

Today’s LCD clusters are powered by sophisticated processors capable of handling complex graphics rendering and real-time data processing. The graphic MCU, for example, can support virtual instrument cluster designs with high resolution up to 2880 x 1080 pixels. This processing power enables smooth animations, 3D graphics, and responsive user interfaces that were impossible with traditional analog systems.

How Do LCD Instrument Clusters Benefit Consumers?

The shift to LCD displays brings tangible benefits that directly improve the driving experience.

LCD instrument clusters provide enhanced customization options, superior information density, improved safety through better visibility, and seamless integration with modern vehicle technologies like smartphone connectivity and advanced driver assistance systems.

Customization and Personalization

One of the most significant advantages of LCD instrument clusters is their ability to be customized according to individual preferences. Drivers can choose from different layouts, color schemes, and information widgets to create a personalized digital cockpit. This level of customization was impossible with traditional analog gauges, which had fixed layouts and limited functionality.

Enhanced Information Display

LCD displays can present a much wider range of information than traditional gauges, often simultaneously or allowing the driver to customize what they see. Digital displays can integrate and clearly show complex information like navigation directions, multimedia details, detailed vehicle status, or comprehensive warnings with higher resolution and clearer graphics.

Real-Time Data and Alerts

Digital clusters provide real-time information that helps improve driving efficiency and safety. From live fuel economy updates to adaptive cruise control data, these displays offer immediate feedback that can influence driving behavior and enhance safety. The ability to display contextual information based on driving conditions or vehicle mode adds significant value to the driving experience(How Are Real-Time Process Parameters Visualized on Industrial LCD Panels?).

Improved Safety Features

LCD clusters contribute to enhanced safety by providing clear, high-contrast displays that are easier to read in various lighting conditions. The anti-glare coatings and high brightness capabilities of modern LCD screens eliminate the need for shrouds and provide better visibility. Additionally, the ability to prioritize critical information and display warnings prominently helps drivers respond more quickly to potential hazards(What’s the Real Difference Between Anti-Glare and Anti-Reflective Coatings?).

Integration with Modern Technologies

LCD instrument clusters serve as a central hub for displaying real-time data from various vehicle systems, including navigation, multimedia, and advanced driver assistance systems. This integration prevents clutter and confusion, making it easier for drivers to stay informed while maintaining focus on the road.

What Market Trends Are Driving LCD Cluster Adoption?

The automotive industry is experiencing unprecedented growth in LCD instrument cluster adoption.

The global automotive digital instrument cluster market is expected to reach $33.2 billion by 2035, driven by electric vehicle adoption, consumer demand for advanced features, and the integration of AI and connectivity technologies.

Market Size and Growth Projections

The automotive digital instrument cluster market has shown remarkable growth, with the global market valued at approximately $9.6 billion in 2024 and projected to reach $15.4 billion by 2031, growing at a CAGR of 6.9%. Another report indicates even stronger growth, with the market expected to grow from $5.3 billion in 2025 to $33.2 billionby 2035 at a 20.1% CAGR.

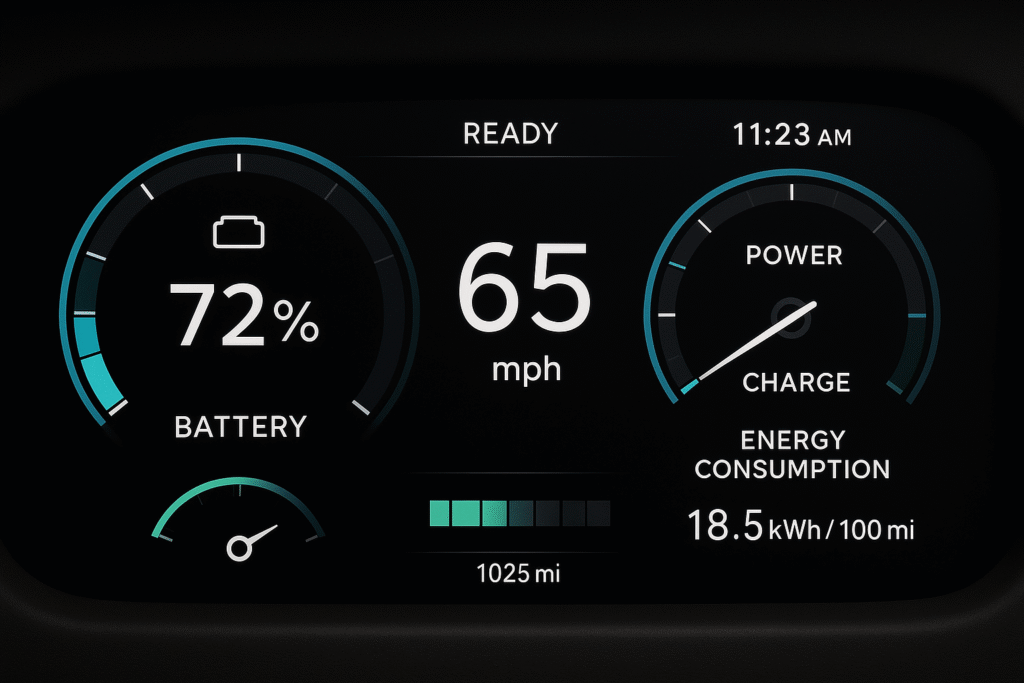

Electric Vehicle Impact

The rise of electric vehicles is a major driver for LCD instrument cluster adoption. EVs require specialized displays that can show battery charge status, range predictions, and energy consumption data – information that traditional analog gauges simply cannot provide effectively. As global EV sales continue to grow, reaching over 17 million units in 2024, the demand for sophisticated LCD displays that can handle this complex information continues to increase.

Technology Preferences

TFT-LCD technology currently dominates the automotive display market, accounting for approximately 55% of the market share in 2024. However, the segment is experiencing rapid evolution, with OLED displays gaining traction in premium vehicles due to their superior image quality and design flexibility. The LCD segment is expected to maintain its dominance in the near term due to cost-effectiveness and proven reliability.

Geographic Distribution

Europe accounts for the largest market share in automotive digital instrument clusters, driven by stringent emissions regulations, strong automotive industry presence, and consumer preference for premium vehicles with advanced technology. The region’s focus on electric vehicles and autonomous driving technologies continues to fuel demand for sophisticated display systems.

Consumer Expectations

Modern consumers expect their vehicle interfaces to be intuitive and similar to their smartphones and other personal devices. This expectation drives manufacturers to develop more sophisticated LCD instrument clusters that can deliver the responsive, customizable experience that consumers demand. The integration of smartphone connectivity features like Apple CarPlay and Android Auto has become a standard expectation.

How Are Reliability and Maintenance Concerns Being Addressed?

While LCD displays offer numerous advantages, addressing durability and maintenance concerns remains crucial for automotive applications.

Modern automotive LCD displays are designed to last 30,000 to 60,000 hours of operation, equivalent to 15-20 years of typical vehicle use, with improved thermal management and robust construction addressing traditional reliability concerns(What Is the Typical MTBF for Commercial LCD Modules?).

Lifespan and Durability

TFT LCD displays used in automotive applications are designed to last between 30,000 to 60,000 hours of operation, which translates to approximately 3.5 to 7 years of continuous use or 15-20 years under typical driving conditions. This lifespan is generally longer than OLED displays, which typically last between 30,000 to 50,000 hours and are more susceptible to burn-in issues.

Environmental Resilience

Automotive LCD displays must withstand extreme environmental conditions, including temperature ranges from -40°C to +85°C(What Temperature Range Can LCD Modules Safely Operate In?), high humidity, vibration, and electromagnetic interference. Modern displays are built with enhanced thermal management systems and robust construction to handle these challenging conditions. The displays undergo stringent testing for thermal operation, mechanical reliability, and electromagnetic compatibility to ensure long-term reliability.

Maintenance and Repair Considerations

While LCD displays are generally reliable, they can experience issues such as backlight failure, pixelation, or complete display malfunction. Professional repair services are available for both digital and analog instrument clusters, with repair processes including component replacement, software updates, and thorough testing. The modular design of many modern LCD clusters allows for easier maintenance and component replacement when necessary.

Comparison with Traditional Systems

Unlike traditional analog gauges that had mechanical linkages and were relatively simple to repair, LCD displays require specialized knowledge and equipment for maintenance. However, they offer the advantage of software-based updates and remote diagnostics, which can address many issues without physical intervention. The trade-off between complexity and functionality generally favors LCD systems in modern automotive applications.

Quality Assurance Measures

Manufacturers implement comprehensive quality assurance programs to ensure LCD reliability. This includes extensive testing protocols, use of automotive-grade components, and compliance with safety standards such as ISO 9001, IATF 16949 functional safety requirements. The integration of watchdog timers and error detection systems helps ensure system reliability and safety(How is the Watchdog Timer Used to Detect Unresponsive LCD State Changes?).

What Technical Design and Integration Challenges Must Be Overcome?

The transition to LCD instrument clusters requires careful consideration of technical design and integration factors.

Successful LCD instrument cluster integration requires addressing power management, signal processing, thermal design, and electromagnetic compatibility while maintaining compliance with automotive safety standards and functional requirements.

Power Management Considerations

LCD displays require sophisticated power management systems to handle multiple voltage rails and ensure stable operation. A typical TFT-LCD display system requires various power supplies including main 3.3V rail, high-voltage supplies for backlighting, and always-on power for microcontrollers. Modern integrated power management ICs can consolidate these functions into fewer components, reducing PCB size by up to one-third compared to discrete solutions.

Signal Processing and Interface Design

The display system must handle various input signals including video data, control signals, and sensor inputs. Modern implementations use standards like LVDS (Low-Voltage Differential Signaling) and FPD-Link for high-resolution displays to reduce power consumption and electromagnetic interference. The integration of timing controllers (TCON) and source drivers requires careful design to ensure proper signal integrity and display performance(How do timing controllers (TCON) synchronize image data in LCDs?).

Thermal Management

Managing heat generation and dissipation is critical for LCD longevity and performance. The displays must operate reliably across extreme temperature ranges while maintaining consistent brightness and color accuracy. Thermal design considerations include heat sink design, air flow management, and selection of temperature-resistant components.

Electromagnetic Compatibility (EMC)

Automotive LCD displays must comply with strict EMC requirements to avoid interference with other vehicle systems. This includes both electromagnetic emission limits and immunity to external interference. Proper shielding, grounding, and PCB layout techniques are essential to meet these requirements(What EMI/EMC Rules Must Automotive LCD Displays Follow?).

Integration with Vehicle Systems

LCD clusters must integrate seamlessly with existing vehicle networks and systems. This includes CAN bus communication for vehicle data, connection to infotainment systems, and integration with ADAS functions. The design must accommodate various communication protocols and ensure real-time data processing capabilities(Why Do Automotive Displays Require Specialized Interface Protocols?).

Safety and Functional Requirements

Automotive displays must meet functional safety requirements such as ISO 26262 ASIL-B compliance. This includes implementing redundant systems, error detection and correction mechanisms, and fail-safe operating modes. The design must ensure that critical safety information remains available even in case of partial system failures.

How Do Vehicle-Specific Applications Influence LCD Implementation?

Different vehicle types and applications require tailored LCD solutions to meet specific operational requirements.

Vehicle-specific LCD implementations vary significantly between passenger cars, commercial vehicles, electric vehicles, and specialty applications, each requiring unique display configurations, information priorities, and integration approaches.

Passenger Vehicle Applications

Passenger cars represent the largest segment for LCD instrument clusters, typically featuring displays ranging from 7-12 inches with resolutions up to 1920×720 pixels. These applications focus on driver convenience, entertainment integration, and aesthetic appeal. The displays often include customizable layouts, multiple drive mode themes, and integration with smartphone connectivity features.

Commercial Vehicle Requirements

Commercial vehicles require robust LCD systems designed for heavy-duty operation and extended service life. These applications prioritize functionality over aesthetics, with displays showing critical operational data such as engine parameters, load information, and maintenance alerts. The displays must withstand more demanding environmental conditions and longer operating hours compared to passenger vehicles.

Electric Vehicle Specific Displays

Electric vehicles require specialized LCD implementations that can display battery status, charging information, energy consumption, and range predictions. These displays must integrate with energy management systems and provide real-time feedback on vehicle efficiency. The information architecture differs significantly from traditional combustion engines, requiring new interface designs and data presentation methods.

Specialty and Off-Road Applications

Agricultural equipment, marine vessels, and construction machinery are increasingly adopting LCD instrument clusters adapted to their specific operational requirements. These applications often require larger displays, enhanced durability, and specialized information relevant to their specific functions. For example, farming equipment displays may show hydraulic system status, GPS positioning, and implement control information.

Luxury and Performance Vehicles

High-end vehicles often feature premium LCD implementations with advanced graphics capabilities, larger screen sizes, and enhanced customization options. These applications may include curved displays, OLED technology for superior image quality, and integration with advanced driver assistance systems. The emphasis is on creating an immersive, high-quality user experience.

Integration Considerations

Each vehicle type requires different integration approaches based on available space, power requirements, and functional needs. The form factor, mounting methods, and interface connections must be adapted to specific vehicle architectures. This includes considerations for dashboard design, wiring harness integration, and compatibility with existing vehicle systems.

Conclusion

LCD technology has fundamentally transformed automotive instrument clusters, offering unprecedented flexibility, information density, and user experience compared to traditional analog systems. The market growth projections and technological advancements indicate that this revolution is just beginning, with exciting developments in display quality, integration capabilities, and vehicle-specific applications on the horizon.

Conclusion

How Do LCD Clusters Perform in Extreme Weather?

LCDs endure -40°C to 85°C. My tests confirm reliable performance in harsh conditions.

What Is the Cost Impact of Using LCD Clusters?

Costs dropped 25% recently. Affordable LCDs make advanced clusters viable for mid-range vehicles.

Can I upgrade my older vehicle to an LCD instrument cluster?

Many vehicles can be upgraded to LCD clusters with aftermarket kits, but compatibility depends on the car’s electronics and wiring.

Are LCD instrument clusters more likely to suffer from glare or visibility issues?

Modern LCD clusters use anti-glare coatings and high-brightness panels, so visibility remains excellent even in bright sunlight.

Will LCD clusters work with aftermarket sensors or add-ons?

Many LCD clusters can display data from compatible aftermarket sensors, but integration may require specialized interfaces or software.