To find the dot clock frequency, use this simple formula:

Dot Clock (MHz) = H_res × V_res × Refresh Rate × (1 + Blanking%) ÷ 1,000,000.

For example, with a 320×240 LCD at 60 Hz and 10% blanking, the dot clock is about 5.07 MHz.

This works because it counts all pixels per frame, factors in the extra blanking pixels, and multiplies by how many frames the LCD shows per second.

Getting this calculation right ensures your LCD runs smoothly without flicker or distortion.

It also helps you pick the right hardware and components, like the microcontroller or FPGA, to match the required pixel clock.

What is Pixel Clock and How Does It Relate to Display Frequency?

The pixel clock is a specific clock rate that determines the speed at which pixels are transmitted from the source to the display, directly influencing the display frequency or refresh rate. It synchronizes the transfer of lcd display pixels by defining how frequently the image updates per second, measured in hertz (Hz).

Understanding the pixel clock helps you precisely configure display settings, especially for complex setups involving embedded lcd modules. Adjusting pixel clock affects both resolution frequency and lcd pixel transfer efficiency, ensuring stable and clear images on medium and small size lcd module displays.

Pixel Clock Calculation and Relationship to Resolution and Refresh Rate

The pixel clock can be calculated using the following clock rate formula:

For example, a display configuration with 1920 horizontal pixels, 1080 vertical pixels, and a refresh rate of 60 Hz with a blanking period of 20% will have a pixel clock of around 148.5 MHz. This calculation ensures precise timing regulation for each display pixel.

What is a Blanking Period and Why Does It Matter?

A blanking period refers to intervals between transmitting display pixel data, including horizontal and vertical blanking periods along with synchronization pulses. Its primary function is to provide necessary timing for the display’s internal circuits to reset and prepare for the next frame or line.

Technical Insights on Identifying Blanking Periods

To accurately determine blanking values, consult the manufacturer’s lcd module datasheet or standard timing references such as VESA timing standards. Typically, blanking periods are clearly listed, enabling precise control over lcd development processes and ensuring optimal performance for embedded lcd applications.

How to Extract Precise LCD Timing Data from Datasheets and VESA Tables?

You can accurately obtain LCD timing data by carefully reviewing the lcd module datasheet, which lists essential parameters such as H_total, V_total, H_sync, V_sync, H_backporch, and V_backporch. Additionally, official VESA timing tables provide standardized values that are useful references when configuring embedded lcd and medium or small size lcd modules.

Practically, applying the frequency resolution formula to these extracted values allows you to compute precise blanking intervals and ensures compatibility with your specific display hardware. This method helps establish optimal synchronization for reliable and stable display performance on embedded lcd modules.

Calculating Blanking Intervals Using Timing Data

Use the following steps to accurately calculate blanking intervals:

- Horizontal Blanking Interval = (H_total − Horizontal Active Pixels); typical values range from 160 to 280 pixels depending on resolution.

- Vertical Blanking Interval = (V_total − Vertical Active Lines); typical values range from 20 to 45 lines depending on module type.

Applying these calculations directly from datasheet values ensures precise timing alignment, enhancing pixel data handling efficiency in small to medium lcd module designs.

How Can You Adjust Standard VESA Timings for Embedded and Small LCD Modules?

You can directly modify standard VESA timings slightly to meet specific requirements of embedded or small-size lcd displays. Such adjustments typically involve tweaking the blanking intervals or slight changes in pixel clock frequency while maintaining synchronization integrity.

Technical Insights on Adjusting VESA Timings

When adapting VESA timings, limit adjustments of horizontal or vertical blanking periods by no more than ±5-10% from standard values. For instance, if a standard timing table lists a horizontal blanking of 200 pixels, adjustments to 190-210 pixels typically remain within safe synchronization limits, ensuring stable and clear image performance on embedded lcd displays.

How Do You Accurately Calculate Dot-Clock for an LCD Display?

Accurately calculating the dot-clock involves determining the total pixels per frame, multiplying them by the refresh rate, and converting the resulting pixel rate into megahertz (MHz). This ensures that the LCD display synchronizes correctly, providing stable and clear images without timing errors.

In practice, the calculation process includes clearly identifying active pixels (H_active and V_active), adding the respective horizontal and vertical blanking periods, and finally computing the dot clock using the resulting totals. Proper dot-clock calculation directly influences performance stability, particularly for embedded and small-size lcd modules.

Technical Step-by-Step Dot-Clock Calculation

Follow these steps to precisely calculate the dot-clock:

Total Pixels per Frame:

- H_total = H_active (resolution) + H_blank

- V_total = V_active (resolution) + V_blank

Pixels per Second (Pixel_rate):

- Pixel_rate = H_total × V_total × Refresh_rate

Convert Pixel_rate to MHz:

- Pixel Clock (MHz) = Pixel_rate ÷ 1,000,000

Worked Examples for Dot-Clock Calculation

Example 1: 320×240 pixels at 60 Hz refresh rate, with 10% blanking

- Horizontal Active Pixels (H_active): 320 pixels

- Vertical Active Pixels (V_active): 240 pixels

- Total Horizontal Pixels (H_total): 320 + (320 × 10%) = 352 pixels

- Total Vertical Pixels (V_total): 240 + (240 × 10%) = 264 pixels

- Pixel_rate = 352 × 264 × 60 = 5,576,880 pixels/sec

- Dot Clock: 5,576,880 ÷ 1,000,000 ≈ 5.58 MHz

Example 2: 480×320 pixels at 75 Hz refresh rate, with detailed sync signals

- Horizontal Active Pixels (H_active): 480 pixels, H_blank: 100 pixels (from datasheet)

- Vertical Active Pixels (V_active): 320 pixels, V_blank: 20 pixels (from datasheet)

- H_total: 480 + 100 = 580 pixels

- V_total: 320 + 20 = 340 pixels

- Pixel_rate = 580 × 340 × 75 = 14,790,000 pixels/sec

- Dot Clock: 14,790,000 ÷ 1,000,000 ≈ 14.79 MHz

These calculations clearly demonstrate accurate methods of determining dot-clock frequencies required for reliable display operation.

How Can You Convert Between Frequency and Period if Only Period is Provided?

You can easily convert between frequency and period using simple mathematical conversions if only one of these parameters is given in datasheets or timing tables. This allows you to quickly interpret timing data and correctly configure the pixel clock.

Technical Conversion Between Frequency and Period

- Frequency (Hz) = 1 ÷ Period (seconds)

- Period (seconds) = 1 ÷ Frequency (Hz)

For instance, a pixel clock period of 20 nanoseconds (20 ns) corresponds directly to a frequency calculation:

- Frequency = 1 ÷ 20 × 10⁻⁹ seconds = 50 MHz

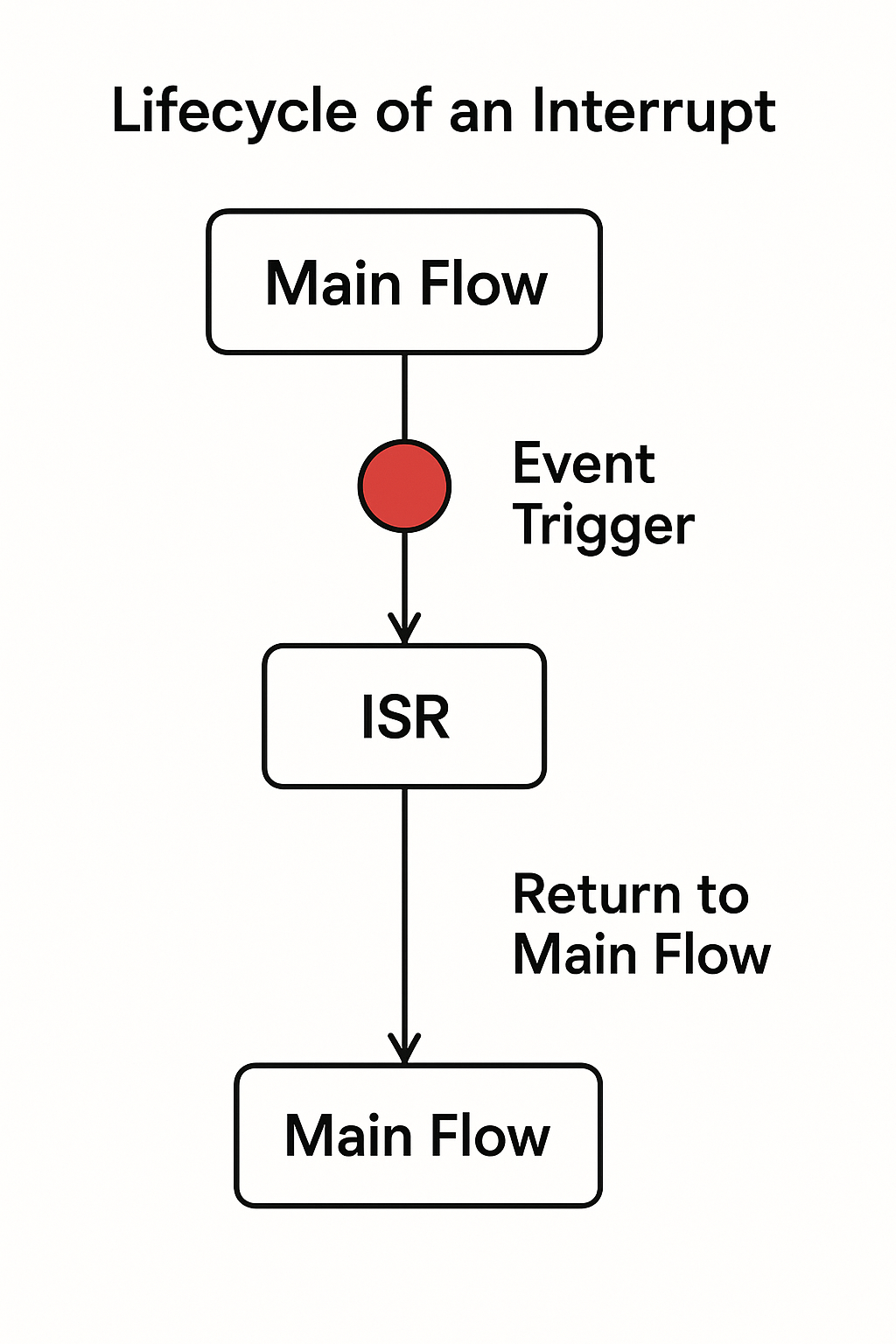

How Do You Implement Dot Clock Generation in Hardware for LCD Displays?

You can generate the dot clock for LCD displays using hardware methods such as MCU timers, PLL (Phase-Locked Loop) circuits, or crystal oscillators. The chosen method directly affects the precision of the clockrate, as well as jitter levels, influencing the overall image quality and stability of the LCD module.

When selecting a hardware solution for embedded lcd applications, you must balance the trade-offs between precise clock frequency control and potential jitter. PLL circuits typically offer flexible frequency adjustments but might introduce jitter, while crystal oscillators provide stable frequencies with minimal jitter at fixed values.

Hardware Methods for Dot Clock Generation

Follow these steps to precisely calculate the dot-clock:

Total Pixels per Frame:

- H_total = H_active (resolution) + H_blank

- V_total = V_active (resolution) + V_blank

Pixels per Second (Pixel_rate):

- Pixel_rate = H_total × V_total × Refresh_rate

Convert Pixel_rate to MHz:

- Pixel Clock (MHz) = Pixel_rate ÷ 1,000,000

Hardware Methods for Dot Clock Generation

Here is a quick comparison of typical hardware methods used for dot clock generation:

| Method | Frequency Precision | Jitter Level | Complexity & Cost |

|---|---|---|---|

| MCU Timer | Moderate | Higher jitter | Low cost, simple |

| PLL Circuit | High (adjustable frequency) | Moderate jitter | Medium complexity |

| Crystal Oscillator | Very high (fixed frequency) | Very low jitter | Simple, moderate cost |

For instance, using a PLL circuit, you can adjust the dot clock to precisely match unusual lcd pixel frequencies that standard oscillators might not support. However, carefully managing jitter is necessary to maintain good signal integrity and stable image quality.

How Does Dot Clock Influence Interface Protocol Selection (Parallel RGB, LVDS, SerDes)?

The chosen dot clock directly determines the suitable interface protocol (Parallel RGB, LVDS, SerDes) for LCD displays, as each protocol requires different pixel serialization rates. Higher dot clocks usually favor LVDS or SerDes interfaces because they effectively handle faster pixel rate transfers.

Dot Clock and Interface Protocols

- Parallel RGB Interface: Ideal for low to moderate pixel clock rates (below 40 MHz), simple wiring but prone to EMI issues at higher frequencies.

- LVDS Interface: Suitable for moderate to high pixel clocks (typically 25 MHz–100 MHz), reduces EMI significantly due to differential signaling.

- SerDes Interface: Best for very high pixel clocks (above 100 MHz), serializes pixel data at high rates, significantly reducing EMI and improving signal integrity.

Clearly matching the dot clock frequency to the appropriate interface ensures stable data transmission and optimal display operation.

What Hardware Considerations Affect LCD Development Regarding Dot Clock?

When developing LCD hardware, you must verify the microcontroller or FPGA can support the required dot clock frequencies. Adequate support prevents issues such as image instability, high electromagnetic interference (EMI), and excessive power consumption.

Technical Considerations for LCD Development

- Microcontroller/FPGA Support: Always confirm your hardware can comfortably handle the necessary pixel clock rate, typically by checking the device’s maximum supported frequency stated in datasheets.

- Power Consumption & EMI: High dot clock frequencies increase both power consumption and EMI emissions; selecting suitable interface protocols and careful PCB layout techniques (like differential lines) can mitigate these effects.

- Signal Integrity: Ensure proper impedance matching, controlled PCB trace lengths, and shielding practices to maintain robust signal integrity, especially at higher dot clock frequencies (above 50 MHz).

How Can You Dynamically Adjust LCD Resolution and Refresh Rate in Embedded Systems?

You can dynamically adjust the resolution and refresh rate of an embedded LCD by recalculating the dot clock frequency in real-time, adapting instantly to changing display requirements. This capability is especially relevant for portable devices, enabling optimized visual performance while controlling power consumption.

Practically, recalculating the pixel clock on-the-fly allows embedded devices to switch smoothly between high-resolution modes for detailed images and lower-resolution modes for efficient power management. Correct runtime adjustment ensures stable image quality without artifacts or synchronization problems.

Steps to Dynamically Recalculate Dot Clock

When adjusting resolution and refresh rate dynamically, follow these critical steps:

- Determine new H_active, V_active, and refresh rate based on current operational requirements.

- Calculate total pixels per frame (H_total and V_total) including recalculated blanking intervals.

- Compute the new pixel clock using:

For instance, switching from a 640×480 at 60 Hz mode to a lower power 320×240 at 30 Hz mode significantly reduces pixel clock frequency, improving battery life in portable embedded lcd devices.

How Do Higher Pixel Clocks Affect EMI and Signal Integrity on LCD Modules?

EMI and Signal Integrity Mitigation Strategies

To mitigate EMI and signal integrity problems at higher pixel clock frequencies (above 50 MHz), consider these design strategies:

- Controlled Slew Rates: Implement controlled slew rates on signal lines to reduce sudden voltage changes that generate EMI, typically by adding series termination resistors.

- Proper PCB Layout: Maintain impedance-controlled traces, differential pairing for interfaces like LVDS or SerDes, and minimized trace lengths. Ground planes should shield sensitive signals to further reduce EMI.

How Can You Create Custom LCD Timings if Datasheets Lack Information?

If an LCD datasheet lacks timing specifications, you can generate your own custom timings by using specialized pixel clock calculator tools available online or within custom spreadsheets. These tools simplify deriving functional pixel clock frequencies and timing intervals.

Generating Custom LCD Timings

Follow this practical approach when creating custom LCD timings:

- Start by estimating blanking intervals (typically 20-30% of active pixels) based on similar standard displays.

- Input active resolution, estimated blanking intervals, and desired refresh rate into a pixel clock calculator tool.

- Verify resulting dot clock frequency aligns with your hardware’s supported frequency range (microcontroller, FPGA, or oscillator limits) to avoid exceeding hardware capabilities or causing visual artifacts.

How Do You Validate and Troubleshoot LCD Pixel Clock and Sync Signals Effectively?

You can effectively validate LCD pixel clock and synchronization signals using test equipment like oscilloscopes or logic analyzers, combined with precise calculations of frequency and timing periods. Performing accurate measurements ensures your LCD setup operates correctly, avoiding issues such as image distortion or synchronization errors.

In practice, using hardware measurement tools allows you to visually confirm the pixel clock frequency, resolution frequency, and correct timing of sync pulses. Comparing these real-world measurements with values from theoretical frequency calculator period tools or manual calculations helps identify discrepancies quickly and accurately.

Measurement Techniques for Pixel Clock and Sync Signals

- Oscilloscope: Captures waveforms visually, allowing you to directly measure pixel clock frequency, sync pulse widths, and identify jitter or noise.

- Logic Analyzer: Records digital signals precisely, helps verify sync signals like H_sync and V_sync, and identifies timing mismatches.

- Frequency Period Calculators: Useful for quick theoretical verification; however, manual calculation using datasheet values tends to provide more precise control, especially when adjusting timing parameters.

For instance, a pixel clock expected at 33 MHz should appear clearly on an oscilloscope with minimal jitter; noticeable deviations or unstable waveforms indicate timing or hardware issues requiring troubleshooting.

What Common Mistakes Should You Avoid When Configuring LCD Pixel Clock?

Common mistakes when configuring the LCD pixel clock include forgetting to include adequate blanking intervals, making rounding errors during frequency-to-period conversions, and exceeding hardware frequency limits. These mistakes lead directly to visible problems such as flicker, artifacts, or complete image instability.

Avoiding Typical Pixel Clock Configuration Pitfalls

- Omitting Blanking Time: Always ensure horizontal and vertical blanking intervals (sync pulses and back-porches) match datasheet or VESA standards; missing or shortening these intervals commonly results in synchronization failures and distorted images.

- Rounding Errors: Avoid rounding off values too early in calculations; maintain accuracy by rounding only at the final stage, ensuring the dot clock matches precisely.

- Exceeding Hardware Limits: Confirm your microcontroller or FPGA’s maximum supported frequency clearly from hardware specifications; for example, pushing beyond a 60 MHz limit for a controller designed for lower frequencies will cause severe visual artifacts or device malfunction.

FAQ

What happens if my pixel clock is slightly lower than required?

A slightly lower pixel clock can result in flickering or distorted images, as the LCD timing signals may not synchronize correctly.

Can I use a higher dot clock frequency than recommended by the datasheet?

Using a higher dot clock than recommended can cause visual artifacts, overheating, increased EMI, or even permanent damage to your LCD module or hardware.

Is it better to choose PLL or crystal oscillator for my LCD dot clock?

If your design needs flexible frequency adjustments, choose PLL circuits; if low jitter and stable fixed frequency matter most, pick crystal oscillators.

Do I always need to measure pixel clock with a scope or analyzer?

Yes, measuring pixel clock signals directly with a scope or logic analyzer helps confirm real-world timing accuracy and quickly identifies any hidden issues.

Can dynamic resolution switching harm my embedded LCD or MCU?

Dynamic resolution switching won’t harm your embedded LCD or MCU if calculated correctly and within hardware frequency specifications; improper calculations can cause instability or visual problems.