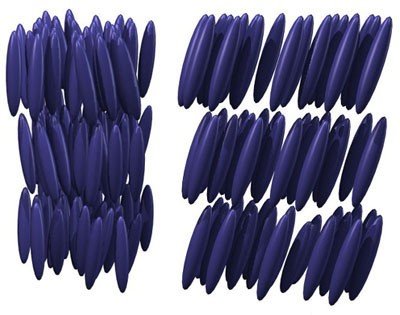

Liquid crystal phases differ in their molecular arrangements, which directly impacts their performance in displays. Nematic liquid crystals have molecules that align in one direction without forming layers, making them ideal for standard LCD screens in phones and TVs. Smectic liquid crystals organize into well-defined layers with molecules aligned within each layer, enabling extremely fast switching speeds used in specialized displays. Cholesteric liquid crystals form a twisted helical structure that can selectively reflect light, making them perfect for low-power, reflective displays like e-readers and electronic shelf labels.

The molecular structure of each liquid crystal phase determines its switching speed, power requirements, and optical properties. Nematic phases offer balanced performance with moderate switching speeds (1-10ms) and reasonable manufacturing costs, which explains their dominance in consumer electronics. Smectic phases can switch up to 1000 times faster than nematics but require more complex manufacturing processes. Cholesteric phases can maintain images without power but have slower refresh rates, making them suitable for static displays rather than video.

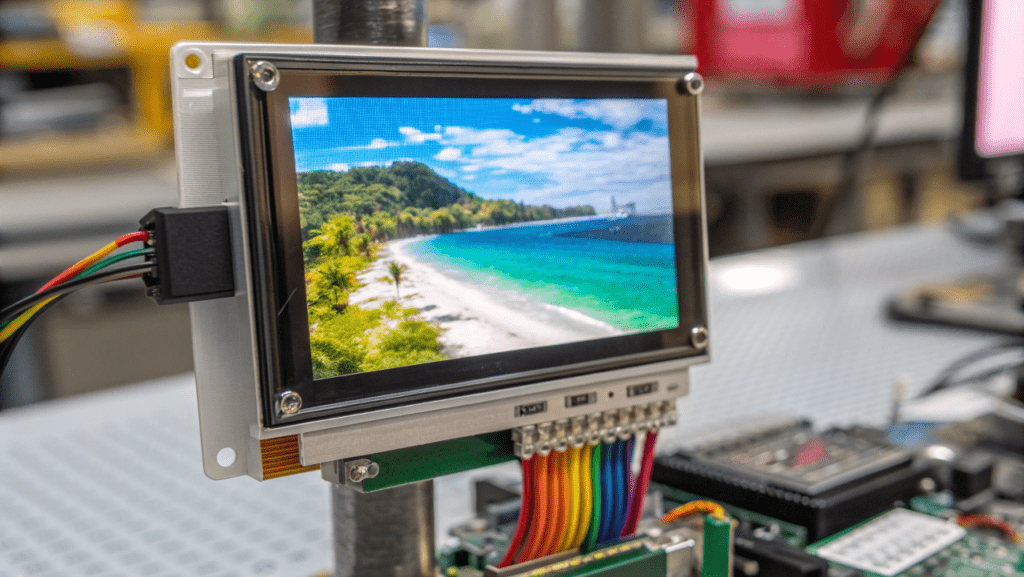

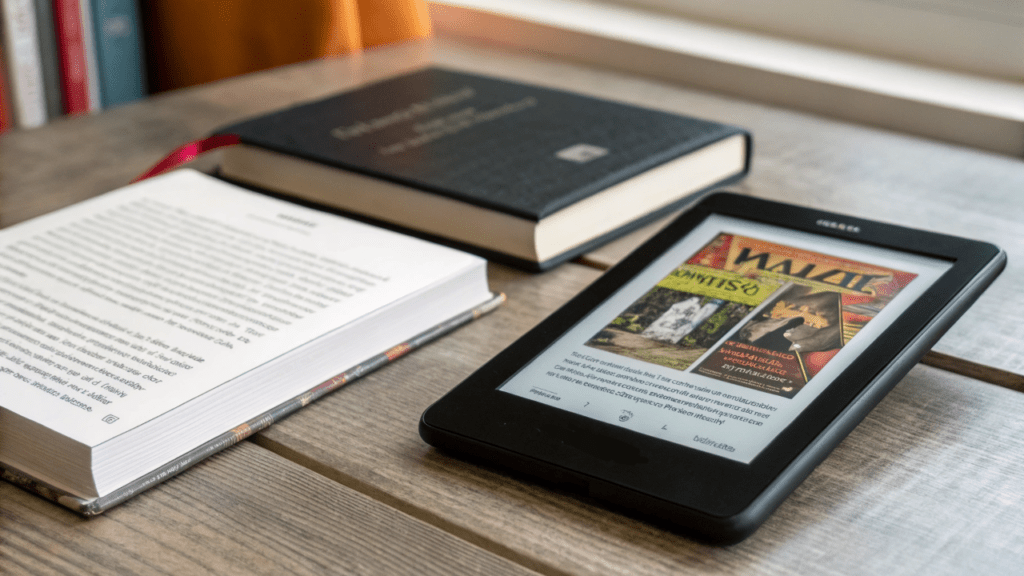

Different display applications require specific liquid crystal properties to meet their performance needs. Standard TVs and monitors use nematic liquid crystals because they provide good color reproduction and acceptable response times at competitive costs. High-speed specialized displays for military or scientific applications often use smectic liquid crystals for their microsecond response times. E-readers and other low-power devices benefit from cholesteric liquid crystals that can display static images indefinitely without consuming power.

HUA XIAN JING provides ODM/OEM service for TN,STN,HTN,FSTN,DFSTN or VA(EBTN) segment lcd module, we are the expert in the field of small and medium-sized LCD, providing professional customized service for 0.42 inch-10.11 inch LCD for the whole world.

What Are Liquid Crystalline Phases?

Types of Liquid Crystalline Phases

Nematic phase: The most common and technologically significant liquid crystal phase where molecules maintain orientational order but no positional order. Molecules align roughly parallel to each other but can move freely.

Smectic phase: Exhibits greater order than nematic phases, with molecules arranged in layers. Within these layers, molecules may be ordered (smectic B) or disordered (smectic A).

Cholesteric phase: Also called chiral nematic, these liquid crystals form a helical structure with molecules arranged in twisted planes.

Discotic phase: Formed by disc-shaped molecules that stack into columns.

Blue phase: Complex three-dimensional structures appearing in highly chiral liquid crystals within narrow temperature ranges.

How Do Liquid Crystals Respond to External Stimuli?

Liquid crystals demonstrate remarkable responsiveness to environmental changes. Temperature variations, electric fields, and magnetic forces can all alter their molecular alignment patterns.

This responsive nature enables their functionality in displays. When voltage is applied to nematic liquid crystal layers in LCD screens, molecules reorient themselves, changing how light passes through them. This property forms the fundamental mechanism behind most modern display technologies including televisions, computer monitors, and smartphone screens.

Technical Response Mechanisms

- Thermotropic behavior: Phase transitions occur at specific temperature points

- Electrooptic effects: Changes in optical properties when exposed to electric fields

- Magnetic susceptibility: Alignment changes in response to magnetic fields

- Photosensitivity: Some liquid crystalline materials change properties when exposed to light of specific wavelengths

What Are the Definitions and Display Uses of Nematic, Smectic, and Cholesteric Liquid Crystals?

Nematic liquid crystals have molecules aligned along one axis but not in fixed positions, making them ideal for twisted nematic (TN) displays in everyday electronics due to their simplicity and low cost. Smectic liquid crystals arrange molecules in layers, which can switch faster but are harder to produce, so they’re used in specialized displays. Cholesteric liquid crystals have a twisted structure that reflects light, perfect for low-power, reflective displays like e-paper.

In TN displays, the liquid crystal layer sits between two polarizers. Without voltage, the twisted molecules rotate light, letting it pass through the second polarizer. When voltage is applied, molecules straighten, blocking the light. This on-off light control forms the pixels in LCD screens.

Smectic phases come in types like smectic A and smectic C. Smectic C has tilted layers, which can be useful for certain display effects. Their ordered structure allows quicker switching, but aligning the layers evenly is tough, limiting their use to advanced prototypes or scientific tools.

Cholesteric liquid crystals reflect specific light colors based on their twist, which can change with temperature. This lets them create color displays without extra lighting, saving energy. They’re also bistable, meaning they can hold an image without power, making them great for e-readers.

Research is looking into blue phase liquid crystals for faster switching and better viewing angles, but they’re still in early stages.

Nematic Liquid Crystals:

- Molecules align parallel to a direction called the director.

- They show birefringence, meaning they bend light differently depending on direction, helping control light.

- Electric fields can shift the director, changing how light passes through.

Smectic Liquid Crystals:

- Molecules form layers with varying order.

- Smectic A has upright molecules, while smectic C has tilted ones.

- Some smectic phases have ferroelectric properties, allowing rapid switching.

Cholesteric Liquid Crystals:

- The director twists in a helix, reflecting specific light wavelengths.

- The helix’s pitch controls the color reflected.

- They can be bistable, holding states without constant power.

How Do These Liquid Crystal Phases Compare in Display Performance?

Nematic phases are the go-to for most displays because they’re easy to make and work well. Smectic phases could be faster but are harder to produce, so they’re less common. Cholesteric phases shine in low-power, reflective displays but switch slowly.

Nematic:

- Switching Speed: Moderate

- Power Consumption: Moderate

- Color: Needs backlighting and filters

- Manufacturing: Easy

Smectic:

- Switching Speed: Fast

- Power Consumption: Varies

- Color: Similar to nematic

- Manufacturing: Difficult

Cholesteric:

- Switching Speed: Slow

- Power Consumption: Low

- Color: Can be built-in but limited

- Manufacturing: Moderate

How Do Nematic, Smectic, and Cholesteric Liquid Crystals Differ in Technical Performance for Displays?

Nematic liquid crystals realign fast under electric fields, enabling quick pixel switches in LCDs. Smectic liquid crystals need precise layer alignment, complicating production, while cholesteric liquid crystals reflect light selectively for energy-efficient displays.

The nematic liquid crystal phase thrives in displays because its molecules shift direction with low voltage, hitting response times around 1-5 milliseconds. Engineers tweak dielectric anisotropy to balance speed and power, ensuring displays react smoothly without draining batteries. In contrast, smectic liquid crystal layers demand exact alignment to avoid defects, which spikes manufacturing costs. Their ferroelectric variants can hit sub-millisecond switches, tempting niche markets despite the hassle.

Cholesteric liquid crystals use their helical twist for Bragg reflection, bouncing back specific light wavelengths to create vivid colors without backlights. Their pitch—the distance for a full helix turn—can be tuned for red, green, or blue, but slow switching limits them to static displays like signs.

Molecular Orientation and Electric Field Response:

- Nematic: Molecules tilt with fields, driven by positive dielectric anisotropy (4-10 typical values).

- Smectic: Layers resist movement, but ferroelectric smectic C flips in microseconds with high polarization (100-200 nC/cm²).

- Cholesteric: Helices unwind partially with fields, but realignment takes 10-100 milliseconds.

Thermal and Environmental Stability:

- Nematic: Stable from -20°C to 80°C; blends widen this range.

- Smectic: Narrower range (20-60°C); humidity can disrupt layers.

- Cholesteric: Broad range (0-100°C); resists humidity due to tight helix packing.

Optical Characteristics:

- Nematic: Wide viewing angles (up to 170°) with IPS tech; contrast ratios hit 1000:1.

- Smectic: Narrower angles (120° max); high contrast (2000:1) possible.

- Cholesteric: Reflective, angle-dependent; contrast varies (10:1 to 50:1).

Manufacturability and Scalability:

- Nematic: Mature production; costs ~$0.01/cm² for panels.

- Smectic: Complex alignment raises costs to $0.05/cm².

- Cholesteric: Simple for e-paper but niche, costing $0.02/cm².

What Limits the Practical Use of Smectic and Cholesteric Phases in Mainstream Displays?

Smectic phases face alignment challenges, slowing production and raising costs. Cholesteric phases switch too slowly for video but excel in low-power static displays.

- Smectic Challenges: Misaligned layers cause light leakage, cutting contrast. Precision equipment can fix this but adds 20-30% to costs.

- Cholesteric Limits: Slow response (100 ms+) suits e-readers, not TVs. Their memory effect saves power, holding images without voltage.

- Emerging Uses: Liquid crystal paint with cholesteric traits could lead to color-shifting coatings, while liquid crystal water research explores bio-compatible displays.

How Are Different Liquid Crystal Phases Used in Modern Display Technologies?

Different liquid crystal phases are used according to their unique properties: nematic phases dominate mainstream displays like TVs and phones, smectic phases appear in specialized high-speed displays, and cholesteric phases excel in low-power reflective displays like e-readers.

The display industry has strategically matched liquid crystal phases to application needs. Nematic liquid crystals have become the backbone of the consumer electronics industry because they offer reliable performance at reasonable manufacturing costs. Their moderate switching speeds and good optical properties make them suitable for most everyday devices. Meanwhile, specialized applications that require either ultra-fast response times or extremely low power consumption rely on smectic and cholesteric phases respectively.

Applications by Liquid Crystal Phase Type

Nematic LCD Applications:

- Twisted nematic (TN): Budget monitors, calculators, industrial displays

- In-plane switching (IPS): Premium smartphones, professional monitors

- Vertical alignment (VA): High-contrast televisions, gaming monitors

- Response times: 1-10ms in modern implementations

- Viewing angles: 60-178° depending on configuration

- Market share: >90% of all liquid crystal displays

Smectic LCD Applications:

- Ferroelectric displays: Military heads-up displays, scientific instruments

- Surface-stabilized ferroelectric LCDs: High-speed optical shutters

- Response times: As low as 10μs (microseconds)

- Binary switching states: Excellent for field-sequential color

- Operating temperature range: Typically narrower than nematic displays

- Applications requiring microsecond switching: Machine vision, 3D shutter glasses

Cholesteric LCD Applications:

- Electronic shelf labels: Retail price displays that update infrequently

- E-readers: Low-power reading devices

- Outdoor signage: Information displays in harsh lighting conditions

- Power consumption: Near-zero when image is static

- Sunlight readability: Superior to other technologies without backlighting

- Color capabilities: Can produce vivid colors without filters or backlights

Why Is Nematic Phase Dominant in Commercial Displays?

The dominance of nematic liquid crystal phases in commercial displays stems from their manufacturing advantages. Production scalability, temperature stability, and reasonable performance across most metrics have made them the industry standard.

Nematic LCDs benefit from decades of manufacturing optimization, allowing for efficient production of large panels with high yields. While smectic displays offer faster switching and cholesteric displays provide better power efficiency, neither can match the overall balance of cost and performance that nematic displays deliver. This explains why your smartphone, computer monitor, and television likely all use some variation of nematic liquid crystal technology.

Technical Comparison for Display Applications

| Phase Type | Response Time | Power Efficiency | Manufacturing Complexity | Viewing Angle | Color Reproduction |

|---|---|---|---|---|---|

| Nematic | 1-10ms | Moderate | Low | Good to Excellent | Excellent with color filters |

| Smectic | 10μs-1ms | Moderate | High | Good | Good with sequential color |

| Cholesteric | 10-100ms | Excellent | Moderate | Excellent | Good in reflective mode |

How Are Emerging Applications Utilizing Specialized Liquid Crystal Phases?

Emerging applications are leveraging the unique properties of specialized liquid crystal phases. Medical imaging, augmented reality, and smart windows represent growing markets that benefit from specific liquid crystalline properties.

Ferroelectric smectic displays enable ultra-fast shuttering needed for advanced 3D imaging systems. Cholesteric formulations are finding new uses in energy-efficient smart windows that can switch between transparent and privacy modes. Meanwhile, polymer-stabilized blue phase liquid crystals—a specialized type with cubic molecular arrangement—are being developed for next-generation displays with microsecond response times and simplified manufacturing compared to traditional smectic displays.

How Do Nematic, Smectic, and Cholesteric Liquid Crystals Compare in Display Performance?

Liquid crystals play a vital role in modern display technology, and their performance hinges on three key factors: response time, stability under temperature changes, and interactions with electric fields. The three main phases—nematic, smectic, and cholesteric—each bring unique strengths and challenges to the table. Below, we’ll explore how these phases stack up in display applications, diving into technical specifics to highlight their differences.

Response Time

- Nematic Liquid Crystals: These have a slower response time, typically ranging from 5-10 milliseconds. The loose molecular alignment in nematic phases means molecules take longer to reorient when triggered, making them suitable for standard displays like TVs but less ideal for fast-paced applications.

- Smectic Liquid Crystals: With their tightly packed, layered structure, smectic phases switch much faster, often below 1 millisecond. This speed makes them perfect for dynamic displays, such as those in gaming monitors or high-precision scientific tools.

- Cholesteric Liquid Crystals: Response times here vary widely, from 10-100 milliseconds, depending on the setup. They’re optimized for static images rather than motion, shining in devices like e-readers where holding an image without power is key.

Stability and Temperature Effects

- Nematic Liquid Crystals: Nematic phases work across a broad temperature range, roughly -20°C to 80°C, but they struggle at extremes. Cold temperatures increase viscosity, slowing response, while heat can disrupt alignment, affecting clarity.

- Smectic Liquid Crystals: Thanks to their layered molecular arrangement, smectic phases offer greater stability, typically between 20°C and 60°C. However, they’re sensitive to temperature shifts—above 50°C, layer disruption can trigger unwanted phase changes.

- Cholesteric Liquid Crystals: These stand out for their stable reflective properties, holding steady from 0°C to 100°C. Temperature does affect the helix pitch (shifting by about 0.1 nm/°C), which alters reflected colors, a trait used in specialized displays.

Electric Field Interactions

- Nematic Liquid Crystals: Nematic phases reorient easily under low voltages, usually 1-5 volts, with a threshold as low as 0.5-1 volt. This energy efficiency makes them a staple in everyday devices like smartphones and laptops.

- Smectic Liquid Crystals: These require stronger electric fields, around 10-20 volts, due to their rigid layers. In ferroelectric smectic phases, spontaneous polarization can hit 100-200 nC/cm², demanding precise control that complicates their use.

- Cholesteric Liquid Crystals: Unlike the others, cholesteric phases don’t reorient fully. Fields above 10 V/μm unwind their helical structure, changing reflectivity rather than alignment—a feature exploited in reflective signage or bistable displays.

Technical Details at a Glance

Based on all five outlines:

| Property | Nematic | Smectic | Cholesteric |

|---|---|---|---|

| Response Time | 5-10 ms (slower) | <1 ms (faster) | 10-100 ms (variable) |

| Temperature Range | -20°C to 80°C | 20°C to 60°C | 0°C to 100°C |

| Field Requirement | 1-5 V (low power) | 10-20 V (higher power) | >10 V/μm (reflectivity) |

How Does Viewing Angle Performance Compare Between Liquid Crystal Phases?

Viewing angle performance varies significantly between different liquid crystal implementations. Standard TN nematic displays have limited viewing angles (typically ±45° vertically), while IPS nematic configurations achieve nearly 180° viewing angles by keeping molecules parallel to the screen.

Smectic displays typically offer moderate to good viewing angles depending on their implementation. Cholesteric displays excel with natural wide viewing angles in reflective applications without requiring additional optical films. These viewing angle differences directly influence user experience, with professional applications generally requiring wider viewing cones than personal devices.

What Are the Key Advantages and Limitations of Different Liquid Crystal Phases?

The key advantages and limitations vary by phase: nematic phases offer cost-effectiveness and manufacturing maturity but have moderate response times; smectic phases provide ultra-fast switching but face manufacturing challenges; cholesteric phases excel in power efficiency but have limited refresh rates.

Display engineers must carefully consider these tradeoffs when selecting materials. Nematic liquid crystals dominate the market because their balanced properties suit most consumer applications. While not perfect in any single metric, they provide reasonable performance across viewing angle, color reproduction, response time, and cost. This makes them the go-to choice for mainstream displays where manufacturing scalability and reliability are paramount.

Comparative Analysis of Liquid Crystal Phases for Displays

Nematic Phase Advantages:

- Manufacturing maturity: Established high-volume production processes

- Cost efficiency: Typically $5-15 per square foot of display area

- Wide operating temperature range: Generally -20°C to 70°C

- Continuous gray scale: Analog voltage control allows precise brightness levels

- Compatibility with thin-film transistor (TFT) backplanes

- Supply chain robustness: Multiple material suppliers globally

Nematic Phase Limitations:

- Response times: Limited to milliseconds range (problematic for some VR/AR)

- Viewing angle: Requires compensation films in many configurations

- Continuous power consumption: Requires constant voltage to maintain image

- Contrast ratio: Typically 1000:1 to 5000:1 (lower than OLED)

- Backlight dependency: Requires separate light source

- Limited flexibility for curved or bendable implementations

Smectic Phase Advantages:

- Switching speed: As fast as 10-100 microseconds

- Binary switching states: Excellent for field-sequential color without blur

- Memory effect: Some configurations retain state briefly without power

- High contrast potential: Sharp transitions between states

- Potential for higher resolution: Smaller pixel geometries possible

- Superior performance in extreme environments (specialized military displays)

Smectic Phase Limitations:

- Manufacturing complexity: Precise layer alignment requirements

- Narrow temperature operating range: Typically 20-40°C without special formulations

- Higher driving voltages: Often 15-30V versus 3-5V for nematic

- Cost: 3-10× higher than comparable nematic displays

- Limited supplier base: Fewer companies specialize in smectic materials

- Cell gap sensitivity: Performance highly dependent on precise spacing

Cholesteric Phase Advantages:

- Bistable operation: Near-zero power consumption for static images

- Reflective viewing: Excellent readability in bright conditions

- No polarizers required: Higher optical efficiency

- Color without filters: Selective reflection based on helical pitch

- Wide viewing angles in reflective mode

- Robust against pressure/physical stress

Cholesteric Phase Limitations:

- Slow refresh rates: Typically 100-500ms

- Limited color gamut: 40-60% of standard RGB

- Complex driving schemes: Requires specialized controllers

- Temperature sensitivity of color: ~2nm wavelength shift per °C

- Limited contrast ratio: Typically 10:1 to 15:1

- Poor performance in low light without supplemental illumination

Why Do Different Applications Require Specific Liquid Crystal Phases?

Different applications prioritize specific performance metrics that align with particular liquid crystal phases. Fast response times are crucial for virtual reality displays to prevent motion sickness, making smectic phases attractive despite their cost. E-readers prioritize power efficiency and sunlight readability, making cholesteric phases ideal despite their slower refresh rates.

Traditional displays like televisions and monitors benefit from nematic phases’ balance of good-enough performance across multiple metrics at reasonable manufacturing costs. Medical displays might prioritize accuracy and reliability, while automotive displays need extreme temperature stability. These application-specific requirements explain why no single liquid crystal phase dominates all display markets.

Application-Specific Phase Selection

| Application | Primary Requirements | Preferred Phase | Key Reason |

|---|---|---|---|

| Smartphones | Efficiency, color, response | Nematic (IPS) | Balance of properties |

| E-readers | Power efficiency, readability | Cholesteric | Bistable operation |

| VR headsets | Ultra-fast response, low blur | Smectic/Blue Phase | Microsecond switching |

| Outdoor signage | Sunlight visibility, durability | Cholesteric | Reflective operation |

| Medical monitors | Accuracy, reliability, angle | Nematic (IPS) | Mature technology |

| Automotive displays | Temperature range, longevity | Special Nematic | Environmental stability |

How Are Hybrid and Composite Systems Addressing Traditional Limitations?

Hybrid and composite liquid crystal systems are addressing traditional limitations by combining the benefits of multiple phases. Polymer-stabilized liquid crystal systems improve temperature stability and mechanical robustness while maintaining the optical properties of their base phase.

Blue phase liquid crystals—which exist in a narrow temperature range between cholesteric and isotropic phases—offer extremely fast response times without the alignment layer requirements of smectic displays. Polymer-network liquid crystals improve switching speed in nematic systems. These emerging approaches demonstrate how material science advances continue to overcome the inherent limitations of pure liquid crystal phases.

Emerging Hybrid Technologies

- Polymer-stabilized blue phase: Sub-millisecond response without alignment layers

- Polymer-dispersed liquid crystals: Switchable opacity without polarizers

- Dual-mode cholesteric: Both reflective and transmissive operation

- Polymer-stabilized ferroelectric: Wider temperature range than pure smectic

- Optically compensated bend mode: Faster nematic response with specialized cell design

Comparison with Alternative Technologies

Liquid Crystal Displays (LCDs) have long been a cornerstone of display technology, but they face competition from alternatives like Organic Light-Emitting Diodes (OLEDs) and Light-Emitting Diode (LED)-based displays. This section compares LCDs with OLEDs and clarifies the distinction between LED-backlit LCDs and true LED displays, highlighting their strengths and roles.

Liquid Crystal Displays vs. OLEDs

A Liquid Crystal Display (LCD) uses liquid crystals—special materials that can change their orientation under an electric field—to control light from a backlight, typically creating images on screens like TVs or monitors. In contrast, OLEDs use organic compounds that emit light when electrified, eliminating the need for a backlight. Here’s how they stack up:

- Contrast Ratio: OLEDs excel with superior contrast, offering true blacks since each pixel can turn off completely. LCDs, reliant on a constant backlight, experience light leakage, resulting in lower contrast ratios (e.g., 1,000:1 vs. OLED’s near-infinite contrast).

- Cost: LCDs are more cost-competitive. Their mature manufacturing processes make them cheaper to produce, especially for larger screens, while OLEDs remain pricier due to complex production.

- Color Accuracy: Both deliver vibrant colors, but OLEDs often edge out with deeper blacks and more vivid hues, thanks to their self-emissive nature.

- Viewing Angles: OLEDs maintain color consistency across wider angles (up to 170°), while LCDs may distort colors beyond 160°.

- Lifespan: LCDs typically outlast OLEDs, which can suffer from burn-in—permanent image retention—over time.

Liquid Crystal Displays vs. LEDs

The comparison between LCDs and LEDs often involves confusion due to terminology. Here, we distinguish between LED-backlit LCDs (a type of LCD) and true LED displays (a distinct technology), both of which use LEDs but in different ways.

LED-Backlit LCDs

These are still LCDs at their core, using liquid crystals to modulate light. The twist? They swap traditional fluorescent backlights for LEDs, enhancing efficiency and color. Examples include most modern TVs, computer monitors, and laptop screens.True LED Displays

In true LED displays, each pixel is made of individual red, green, and blue LEDs, directly emitting light without liquid crystals. These are commonly seen in large-scale applications like billboards, stadium scoreboards, and outdoor signage.Key Differences:

- Technology: LED-backlit LCDs rely on liquid crystals with an LED backlight, while true LED displays use LEDs as the pixels themselves.

- Applications: LED-backlit LCDs dominate consumer electronics for close-up viewing. True LED displays shine in large, outdoor settings where visibility from a distance matters.

- Brightness: True LED displays are far brighter (often 5,000+ nits), ideal for sunlight, compared to LED-backlit LCDs (up to 1,000 nits).

- Pixel Density: LED-backlit LCDs offer high resolution for detailed images up close. True LED displays have larger pixels, suited for far-off viewing.

- Cost: True LED displays are costlier per square foot due to the number of LEDs required.

Related Articles:

How Do You Drive Transflective LCD Modes Successfully?

How Do Brightness Levels Impact Color Accuracy in LCD Displays?

What EMI/EMC Rules Must Automotive LCD Displays Follow?

What Is Circular Polarization and How Does It Improve LCD Displays?

What Is Embedded DisplayPort (eDP) and Why Is It Used in Modern Devices?

FAQ

What causes the color shifts in cholesteric displays when temperature changes?

Temperature changes alter the pitch of the helical structure in cholesteric liquid crystals (approximately 2nm wavelength shift per °C), which directly affects which wavelengths of light are reflected, causing visible color shifts in displays as environmental temperatures fluctuate.

Can smectic liquid crystals be used in consumer TVs and monitors?

While technically possible, smectic liquid crystals are rarely used in consumer TVs and monitors due to their significantly higher manufacturing costs, more complex driving requirements, and narrower operating temperature ranges compared to nematic liquid crystals.

How do blue phase liquid crystals differ from the three main phases discussed?

Blue phase liquid crystals represent a specialized phase that exists in a narrow temperature range between cholesteric and isotropic phases, featuring a cubic molecular arrangement that enables microsecond response times without requiring alignment layers, potentially combining the speed advantages of smectic phases with simpler manufacturing.

Are there any liquid crystal displays that work without electricity?

Yes, bistable cholesteric liquid crystal displays can maintain an image indefinitely without power after the initial setting, making them ideal for electronic shelf labels, e-readers, and other applications where content changes infrequently and power efficiency is critical.

What determines the viewing angle limitations in different liquid crystal displays?

Viewing angle limitations primarily result from the orientation of liquid crystal molecules relative to the display surface and the observer; TN panels have poor vertical viewing angles because the effective birefringence changes significantly when viewed from above or below, while IPS and VA technologies align molecules differently to minimize these variations and achieve wider viewing angles.