You see them everywhere – from your digital watch to industrial equipment – but most people don’t understand what makes these simple displays so reliable and cost-effective.

A monochrome LCD display shows information in a single color, typically black text on a white background, using liquid crystal technology to control light transmission through pixels.

After 13 years in the LCD industry, I’ve seen countless clients choose monochrome displays for their projects. Let me share what I’ve learned about these essential components.

How Does a Monochrome LCD Display Work?

Monochrome LCDs operate on a simple principle that I explain to every new client who visits our factory.

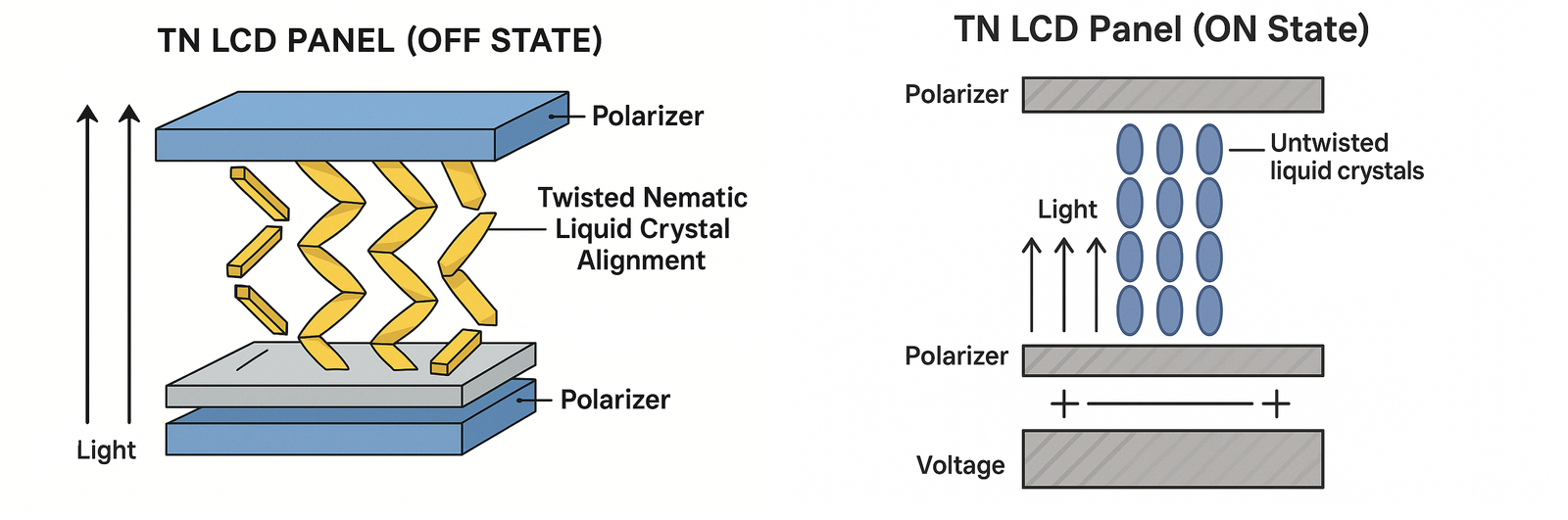

Monochrome LCDs work by using liquid crystals that twist and untwist to control light passage, creating visible patterns when voltage is applied to specific segments or pixels.

The Basic Components

Every monochrome LCD contains several key layers that work together:

| Layer | Function | Material |

|---|---|---|

| Glass Substrate | Structural support | Thin glass sheets |

| Transparent Electrodes | Apply voltage | Indium Tin Oxide (ITO) |

| Liquid Crystal | Light control | Nematic liquid crystals |

| Polarizing Filters | Block/allow light | Polarized film |

| Backlight (optional) | Light source | LED or EL |

The Working Process

The process happens in microseconds. When I apply voltage to specific electrodes, the liquid crystals align in a particular direction. This alignment either blocks or allows light to pass through the polarizing filters.

In a reflective display, ambient light bounces off the back reflector. In a transmissive display, the backlight provides illumination. The liquid crystals act like tiny shutters, opening and closing to create the desired pattern.

Voltage Control Systems

Most monochrome LCDs use multiplexing to control multiple segments efficiently. I’ve worked with duty cycles ranging from 1:2 to 1:240, depending on the complexity of the display.

Why Does a Monochrome LCD Only Show One Color?

This question comes up in almost every client meeting, especially from those considering color alternatives.

Monochrome LCDs show only one color because they lack color filters and use a single backlight wavelength, making them simpler and more cost-effective than color displays.

The Absence of Color Filters

Color LCD displays require red, green, and blue filters for each pixel. Monochrome displays skip this entirely. This design choice reduces manufacturing complexity and cost significantly.

Single Wavelength Systems

Most monochrome displays use white light or a specific wavelength. I’ve seen clients request amber, green, or blue backlights for specific applications. The liquid crystal material responds to voltage the same way regardless of color.

Cost and Simplicity Benefits

Removing color filters reduces the number of manufacturing steps. This translates to lower production costs and higher yields. In my experience, monochrome displays cost 60-80% less than equivalent color displays.

How Are Monochrome LCDs Classified?

Classification helps clients choose the right display for their specific needs.

Monochrome LCDs are classified by driving method (passive/active), display type (segment/dot matrix), and lighting (reflective/transmissive/transflective)().

By Driving Method

| Type | Description | Applications |

|---|---|---|

| Passive Matrix | Simple electrode grid | Calculators, watches |

| Active Matrix | TFT-controlled pixels | Industrial HMIs, medical devices |

By Display Type

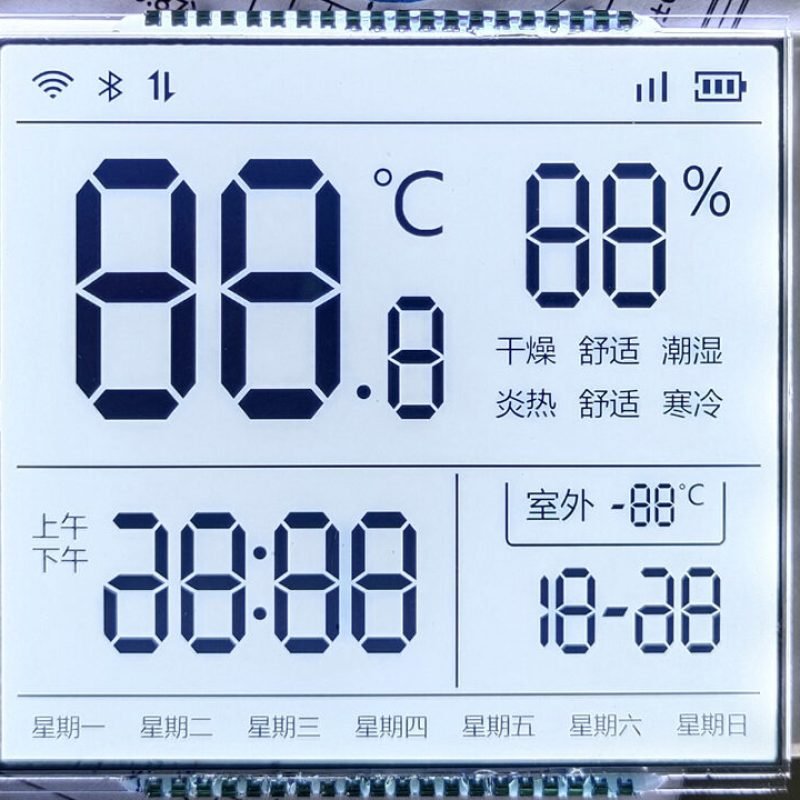

Segment displays work well for numbers and simple symbols. I recommend them for cost-sensitive applications. Dot matrix displays offer more flexibility for text and graphics(Differences Between Segment LCD and Dot Matrix LCD).

By Lighting Method

Reflective displays use ambient light and work best in bright conditions. Transmissive displays need backlighting for dark environments. Transflective displays combine both approaches(What Sets Transmissive, Reflective, and Transflective LCDs Apart?).

By Liquid Crystal Mode

Different LC modes affect viewing angles and contrast(TN, STN, STN, FSTN, STN and EBTN LCD: What Are The Differences?):

- TN (Twisted Nematic): Fast response, low cost

- STN (Super Twisted Nematic): Better contrast, wider viewing angle

- VA (Vertical Alignment): High contrast ratio

- IPS (In-Plane Switching): Excellent viewing angles

How Do Monochrome LCDs Differ from Others Display?

Understanding these differences helps clients make informed decisions.

Monochrome LCDs differ from other displays in color capability, power consumption, cost, and application focus, offering simplicity and efficiency over visual richness.

Comparison with Color LCDs

Color LCDs require three sub-pixels per pixel, increasing complexity. Monochrome displays use single pixels, making them more efficient and reliable.

Power Consumption Differences

| Display Type | Power Consumption | Efficiency |

|---|---|---|

| Monochrome LCD | 10-50mW | High |

| Color LCD | 100-500mW | Medium |

| OLED | 50-200mW | Variable |

| E-paper | 0.1-1mW | Very High |

Contrast and Readability

Monochrome displays often achieve better contrast ratios than color displays. I’ve measured contrast ratios exceeding 1000:1 in premium monochrome displays.

Response Time Performance

Monochrome displays typically respond faster than color displays. Response times under 100ms are common, making them suitable for dynamic applications.

What Are the Main Advantages and Disadvantages of Monochrome LCDs?

Every technology has trade-offs that I discuss honestly with clients.

Monochrome LCDs offer low cost, low power consumption, and high reliability, but sacrifice color information and visual appeal compared to modern display technologies.

Key Advantages

Cost Effectiveness: Manufacturing costs remain 60-80% lower than color alternatives. This makes them ideal for high-volume applications.

Power Efficiency: Low power consumption extends battery life in portable devices. Many of my clients choose monochrome displays specifically for this reason.

Durability: Fewer components mean fewer failure points. I’ve seen monochrome displays operate reliably for over 10 years in industrial environments.

Sunlight Readability: Reflective monochrome displays work excellently in bright conditions where color displays struggle.

Power Consumption Differences

Limited Visual Appeal: Single-color displays can’t compete with modern color displays for user engagement.

Information Density: Without color coding, displaying complex information becomes challenging.

Market Perception: Some clients view monochrome displays as outdated, even when they’re the best technical choice.

Performance Comparison

| Factor | Monochrome LCD | Color LCD | OLED |

|---|---|---|---|

| Cost | Low | Medium | High |

| Power | Very Low | Medium | Variable |

| Contrast | High | Medium | Very High |

| Color | None | Full | Full |

| Lifespan | Very Long | Long | Medium |

How Are Monochrome LCDs Manufactured?

Manufacturing monochrome LCDs requires precision and quality control at every step.

Monochrome LCD manufacturing involves glass preparation, electrode patterning, liquid crystal injection, and final assembly using clean room processes and precision equipment.

Glass Substrate Preparation

The process starts with ultra-clean glass substrates. I’ve seen how even microscopic particles can create defects. The glass goes through multiple cleaning stages using specialized chemicals(What Is a Glass Substrate in the TFT LCD Industry?).

Electrode Pattern Creation

Photolithography Process: Engineers use photomasks to create precise electrode patterns. This step determines the display’s resolution and functionality.

ITO Deposition: Indium Tin Oxide coating provides transparent conductivity. The thickness must be controlled within nanometers for optimal performance(Why Is ITO Glass Vital for LCD Displays and Touchscreens?).

Liquid Crystal Processing

| Step | Process | Critical Parameters |

|---|---|---|

| Alignment | Rubbing/photo-alignment | Direction accuracy ±0.1° |

| Spacing | Bead/post spacers | Thickness ±0.1μm |

| Sealing | UV/thermal cure | Zero contamination |

| Injection | Vacuum fill | Complete coverage |

Assembly and Testing

Final assembly includes polarizer application, backlight integration, and driver IC attachment. Every display undergoes electrical testing and optical inspection(How to Master the LCD Aging Test Process?).

Quality Control Measures

I’ve implemented multiple checkpoints throughout production:

- Incoming material inspection

- Process parameter monitoring

- Visual defect detection

- Electrical performance testing

- Environmental stress testing

Where Are Monochrome LCDs Used?

Monochrome displays serve countless applications across many industries.

Monochrome LCDs are used in industrial equipment, consumer electronics, medical devices, automotive systems, and anywhere simple, reliable information display is needed.

Industrial Applications

Control Panels: Machine operators need clear, reliable displays that work in harsh conditions. Monochrome LCDs excel here(How Are Embedded LCDs Used in Human-Machine Interfaces (HMIs) for Industrial Control Systems?).

Measurement Equipment: Multimeters, oscilloscopes, and test equipment benefit from high-contrast, easy-to-read displays.

Consumer Electronics

| Device Category | Examples | Key Requirements |

|---|---|---|

| Timekeeping | Watches, clocks | Low power, reliability |

| Calculators | Scientific, basic | Cost, durability |

| Appliances | Microwaves, washing machines | Simplicity, visibility |

| Fitness | Heart rate monitors, pedometers | Battery life, readability |

Medical and Healthcare

Medical devices require displays that work reliably for years. Blood glucose meters, patient monitors, and diagnostic equipment often use monochrome displays for their proven reliability.

Automotive Systems

Modern vehicles contain dozens of monochrome displays. Dashboard indicators, climate control panels, and diagnostic displays all benefit from the technology’s reliability and cost-effectiveness(How Are The LCDs Revolutionizing Automotive Instrument Clusters?).

Specialized Applications

Marine Equipment: GPS units, fish finders, and navigation systems use monochrome displays for their excellent sunlight readability.

Aerospace: Aircraft instruments require displays that function reliably in extreme conditions.

Security Systems: Alarm panels and access control systems prioritize reliability over visual appeal.

Conclusion

Monochrome LCDs remain essential in modern electronics, offering unmatched cost-effectiveness, reliability, and power efficiency for countless applications worldwide.

FAQ

How long can a monochrome LCD run before replacement?

With proper drive voltage and cooldown lighting, the panel itself easily exceeds 50,000 h; systems usually retire only when the LED backlight drops to 50% brightness after 70,000–100,000 h.

Will my display still respond in a –30 °C cold start?

Yes—wide-temperature LC mixtures keep segments bistable down to –30 °C, though response time slows; units tested at –30 °C to 85 °C remain readable without damage.

Can Monochrome LCDs Be Customized for Specific Applications?

Yes, monochrome LCDs can be tailored for specific sizes, shapes, and functions. Customization ensures compatibility with devices like medical or industrial equipment.

Is maintenance required for monochrome LCDs?

Monochrome LCDs require almost no maintenance as there are no moving parts and minimal risk of aging under typical conditions.

Is monochrome still relevant when color is everywhere?

Where battery life, glare-free readability, or 10-year field reliability trump aesthetics—industrial meters, wearable sensors, and mission-critical panels—monochrome LCDs remain the optimum choice.