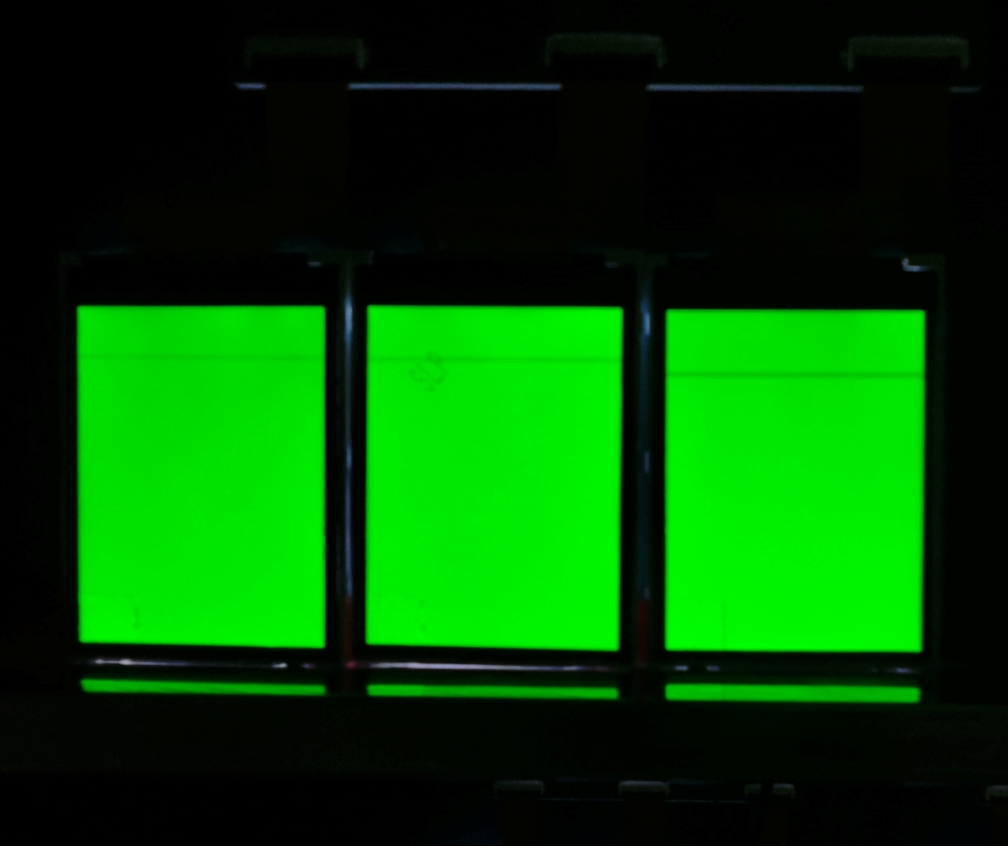

HUA XIAN JING provides a wide range of TFT LCD modules, with sizes spanning from 0.42 inches to 10.11 inches. These modules are available in both TN TFT LCD and IPS TFT LCD technologies, catering to diverse display requirements. To meet the demands of specialized industries, the company also offers a variety of customization options. These include wide operating temperature ranges, ensuring reliable performance in extreme environments, and sunlight-readable displays for optimal visibility in outdoor settings. In addition, HUA XIAN JING supports waterproof customization for applications requiring enhanced durability, as well as anti-glare and anti-reflective treatments to improve screen clarity under challenging lighting conditions.

By providing tailored solutions, HUA XIAN JING aims to address the unique needs of industries that require robust and reliable display technology.

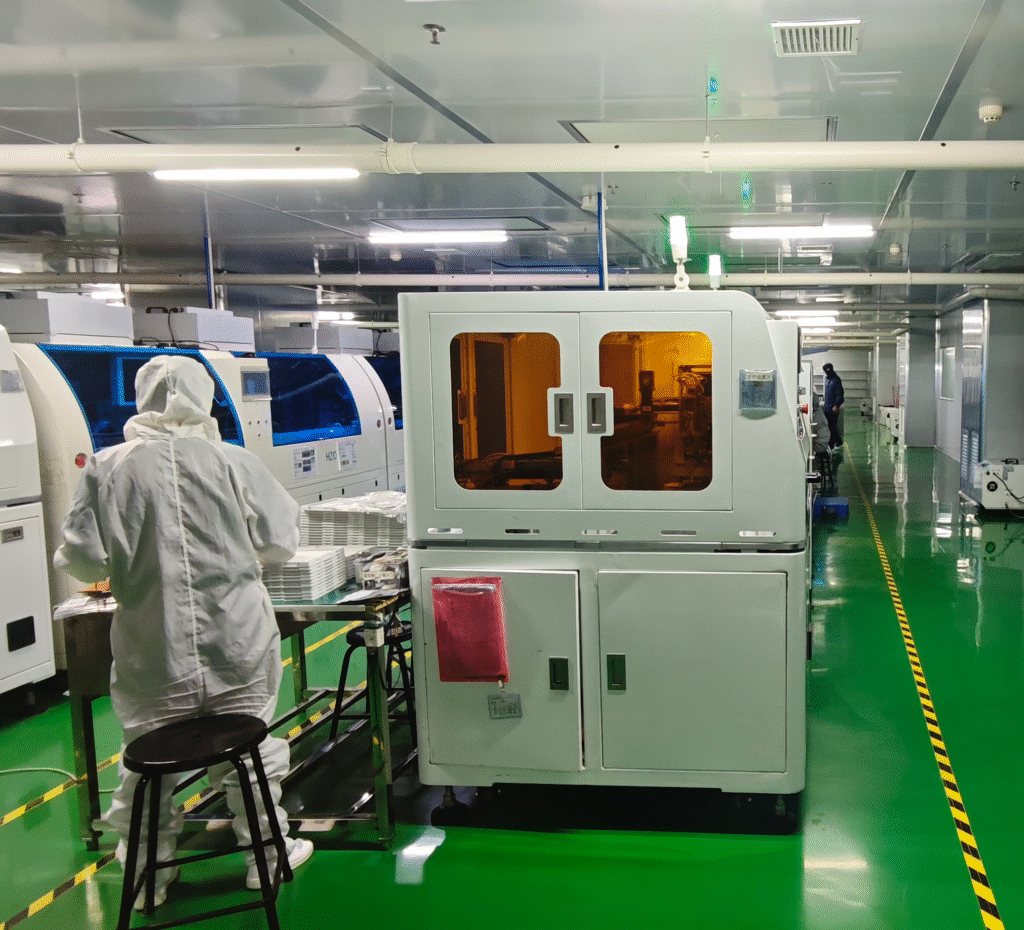

Hua Xian Jing is a manufacturer specializing in small and medium size LCD module, our product size ranges from 0.32 inch – 10.11 inch, and provide ODM/OEM service. Our factory specializes in B2B services, including factories, LCD suppliers, etc. We only provide wholesale service.

Contact us for specific MOQ.

Just tell us what you want, we can select the product that meets your requirements from 10000+ standard products.

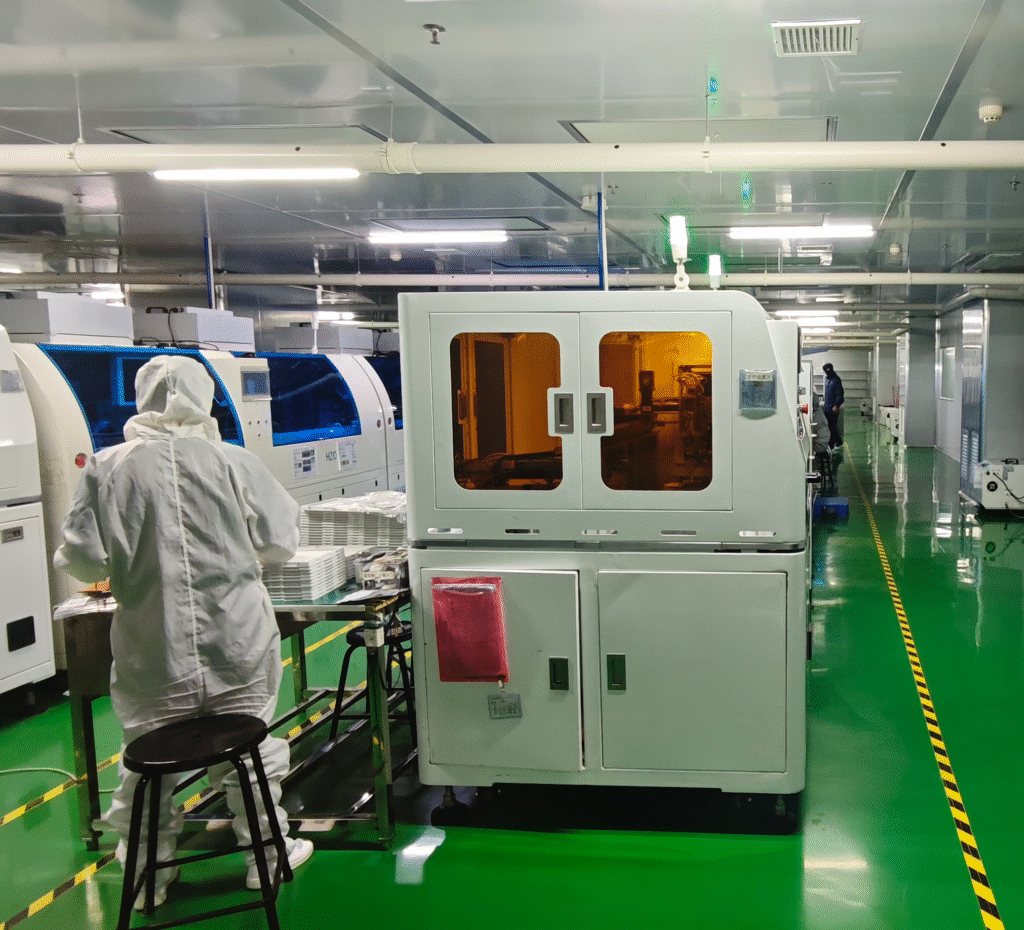

Based on 14 years of experience, our engineers have designed and generated a large number of LCD module prototypes for our customers, when you tell us your product and requirements, we can quickly design LCD module prototypes for you.

The maximum time for our engineers to design the prototype is less than 7 days!

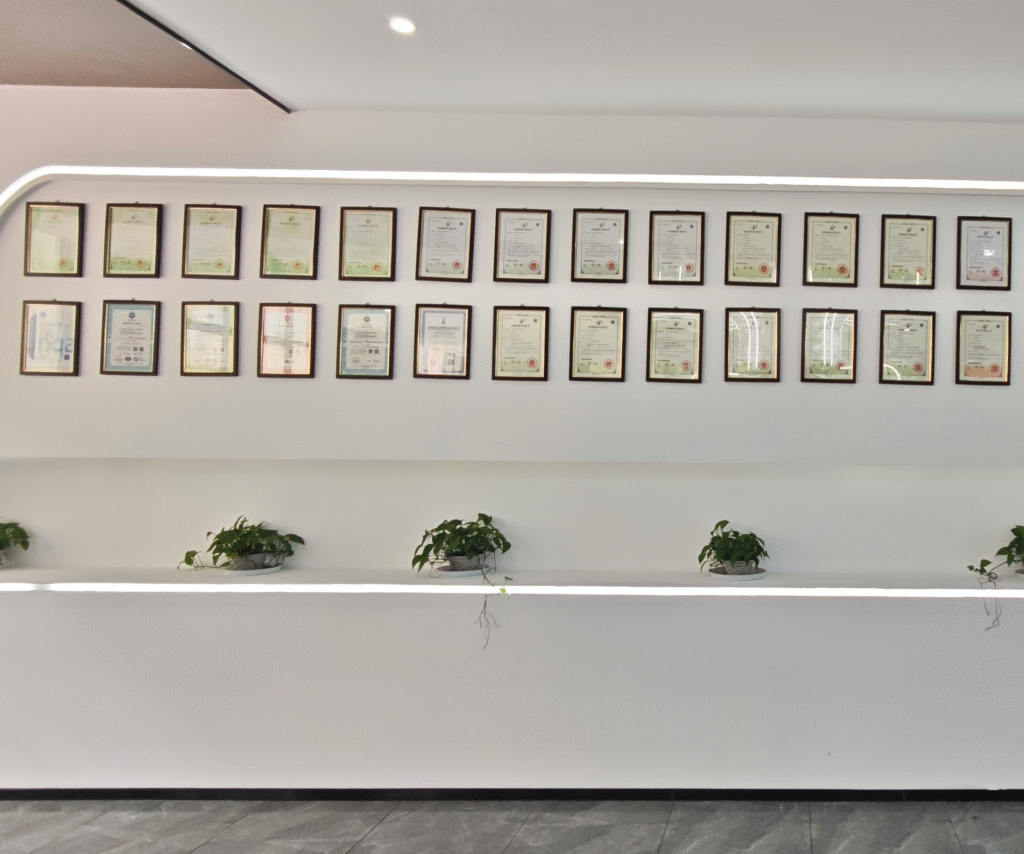

Our factory have passed ISO 9001 quality certification. If your product is in a special industry (eg: medical, aerospace, marine) that requires established industry certification, we will be able to apply for certification for your product.

We provide professional after-sales service. You don’t need to worry about the docking problem of LCD module and your product, we can communicate with your engineers directly to solve the technical problems quickly.

It usually takes 7–10 days to create samples and 30–45 days for mass production.

We’ve got you covered! We’ll share a packing video before shipping and use reliable transport methods. Plus, we offer a 1-year warranty, so if you spot any issues with the LCD module upon arrival, you can request a return.

As a leading LCD module manufacturer in China, HUA XIAN JING often has distributors ship directly from our factory, so delivery times are the same. However, prices may differ, and working directly with us means more convenient after-sales support.

We’ll pick a driver IC that matches your motherboard and communication interface requirements, tailoring everything to your specific needs.

Absolutely! We offer not just standard rectangular panels, but also custom shapes like round, bar-type, hexagonal, octagonal, and more.

Here’s how it works:

Not really. Refurbished LCD panels can have hidden issues, and their lifespan or MTBF (Mean Time Between Failures) isn’t guaranteed.

We’ve designed over 10,000+ LCD modules for customers. That means we can quickly match you with the right solution, ensure stable production, and offer long-term technical support.

HUA XIAN JING has a dedicated lab for testing. We use thermal shock machines to check the operating temperature range and salt spray testers to evaluate corrosion resistance, among other tests.

We provide free LCD prototype design, ongoing technical support, driver code examples, and LCD module datasheets for the long haul.

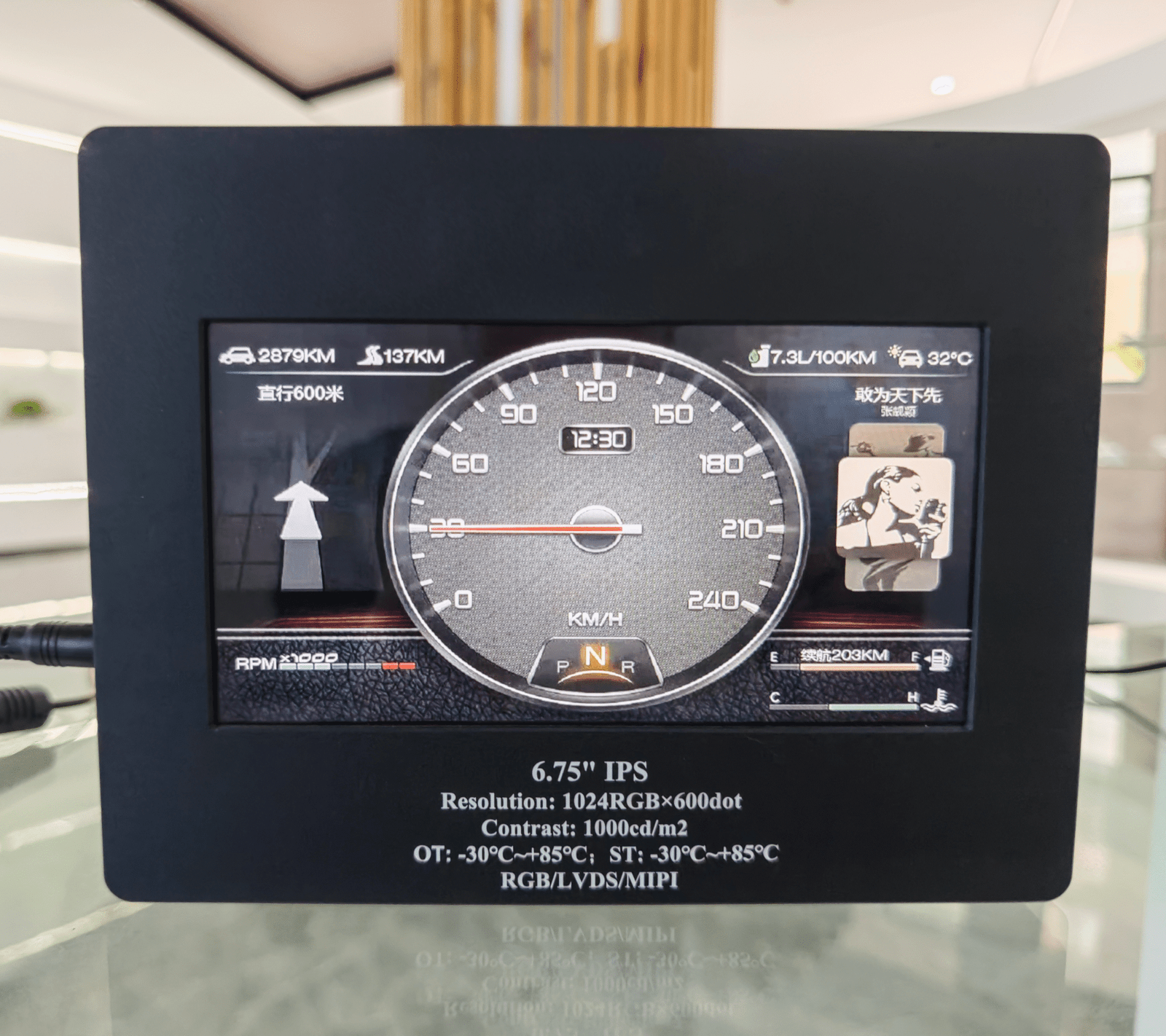

Specialized industry applications refer to sectors such as automotive, medical, and marine, where LCD modules must meet strict operational and safety requirements.

For example, LCD modules used in automotive displays need to be sunlight-readable, operate reliably across a wide temperature range, and withstand shocks and vibrations. Marine applications require additional features like resistance to salt fog corrosion to ensure durability in harsh maritime environments.

These specialized requirements are backed by industry-specific certifications. In the automotive field, LCD modules may need IATF 16949 certification to ensure automotive-grade quality and reliability. In healthcare, standards like IEC 60601 help guarantee electrical safety and performance for medical devices.

The materials used in the LCD will determine the best operating temperature range of the LCD. Ordinary bonding adhesives use double-sided adhesive tape, their operating temperature range is usually in -20°C – 70°C. The use of optical bonding adhesives with optical bonding technology can usually enhance the LCD’s operating temperature range to -40°C – 90°C or more. Optical bonding adhesives are usually made of materials such as acrylic fibers, silicone and optically transparent resins.

For monochrome LCDs, the use of reflective LCDs can ensure that the sunlight can be read clearly, but reflective LCDs can be applied to a small number of scenarios, so the market usually use the transreflective LCD as a centering scheme.

TFT LCD can also be customized to reflective LCD, but adjusting the brightness is often the most practical solution, just need to ensure that the LED backlight brightness in the range of 700-1000 nits, you can achieve the effect of sunlight readable.

Yes, it is important! The touch screen is the outermost layer of the display, and not only does it need to be rugged enough to last, but in many cases it also needs to fulfill some specific functions:

These features require special surface treatment to achieve anti-fingerprint, anti-glare or anti-reflective coatings and other effects.

We are well aware that each industry has special certification standards, such as IATF16949 for automotive, IQC 60601 for medical industry, MIL-STD for military standard, etc. Our strong production capacity can meet these certification standards, but we need you to inform us of your needs in advance.

You can talk to us with complete confidence and we can sign a non-disclosure agreement to keep your secrets 100% confidential.

In our 13 years of experience in LCD ODM/OEM services, there are few such cases. Enterprises often suffer from the discontinuation of raw materials for LCD, and Hua Xian Jing is the source manufacturer of LCD, we can also quickly find a replacement in the face of raw material discontinuation.

For the replacement of existing LCD products, we need you to provide at least one of the following information:

Note: Whether you are replacing an existing LCD or customizing a new LCD module, you will need to meet our minimum order quantity.

Customize the interface, define the Pins, let us know if you have everything ready to interface with the LCD module. You define the arrangement, number of pins, and interfaces, even PCB/FPC lengths, wiring, and ZIP connector/board-to-board docking methods, and you’re ready to dock without having to change anything that’s already in place.

According to lab data, the Mean Time Between Failure (MTBF) of HUA XIAN JING LCD modules is 50,000 – 70,000 hours, which is about 5.4 – 8 years. However, the life expectancy of a TFT LCD is usually affected by temperature, usage environment, and human damage. Of course, we do offer a 1-year warranty to protect the quality of our products.

Download our comprehensive catalog to explore 10,000+ LCD module options in detail:

0.42-10.11 inch TFT LCD

16×2-320×240 COB LCD

8×2-320×240 COG LCD