What Is Color Inversion in LCD Displays?

Color inversion in LCD displays reverses dark and light pixels, creating a high-contrast effect.

Color inversion in LCD displays reverses dark and light pixels, creating a high-contrast effect.

Subpixel rendering boosts the sharpness of images on small LCD modules by controlling each red, green, and blue subpixel separately.

Dot clock frequency counts all pixels per frame, factors in the extra blanking pixels, and multiplies by how many frames the LCD shows per second.

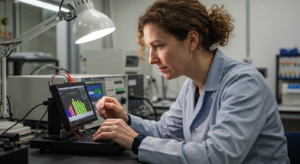

LCDs are tested in labs with dust chambers to check how well they block sand and dust. These tests copy tough conditions to see if particles get inside and affect performance.

LCDs at sub-zero temperatures show slowed response times, washed-out contrast, and visible ghosting when liquid crystals stiffen below 0 °C.

Engineers now use monitor gamma calibration, firmware updates, and factory LUT refresh to match the color gamma correction to standards like sRGB and BT.1886.

Salt spray chambers in testing the usability of LCDs LCD modules resist salt-fog environments using corrosion-resistant materials. They rely on specialized coatings to protect components. Advanced sealing techniques block salt mist entry. MIL-STD-810G and ASTM B117 tests ensure

Engineers test parity error detection in LCD frame buffers by using memory patterns that help expose single-bit faults.

You need to match your LCD module’s interface—such as SPI, I²C, parallel, or advanced types—to what your microcontroller unit offers.

You might face issues like unclear results or missing data about reverse polarity protection diode setups. This guide covers how to handle those problems with practical tips.

Download our comprehensive catalog to explore 10,000+ LCD module options in detail:

0.42-10.11 inch TFT LCD

16×2-320×240 COB LCD

8×2-320×240 COG LCD